Power bogie with independent wheels for 100 percent low-floor light rail vehicles

A power bogie and independent wheel technology, applied in the field of bogies, can solve the problems of inconvenient passage for passengers due to two steps, failure to achieve 100% low-floor vehicles, and difficulty in changing the suspension position of light rail vehicle motors and gearboxes, etc., to achieve The effect of lower floor surface and low floor requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

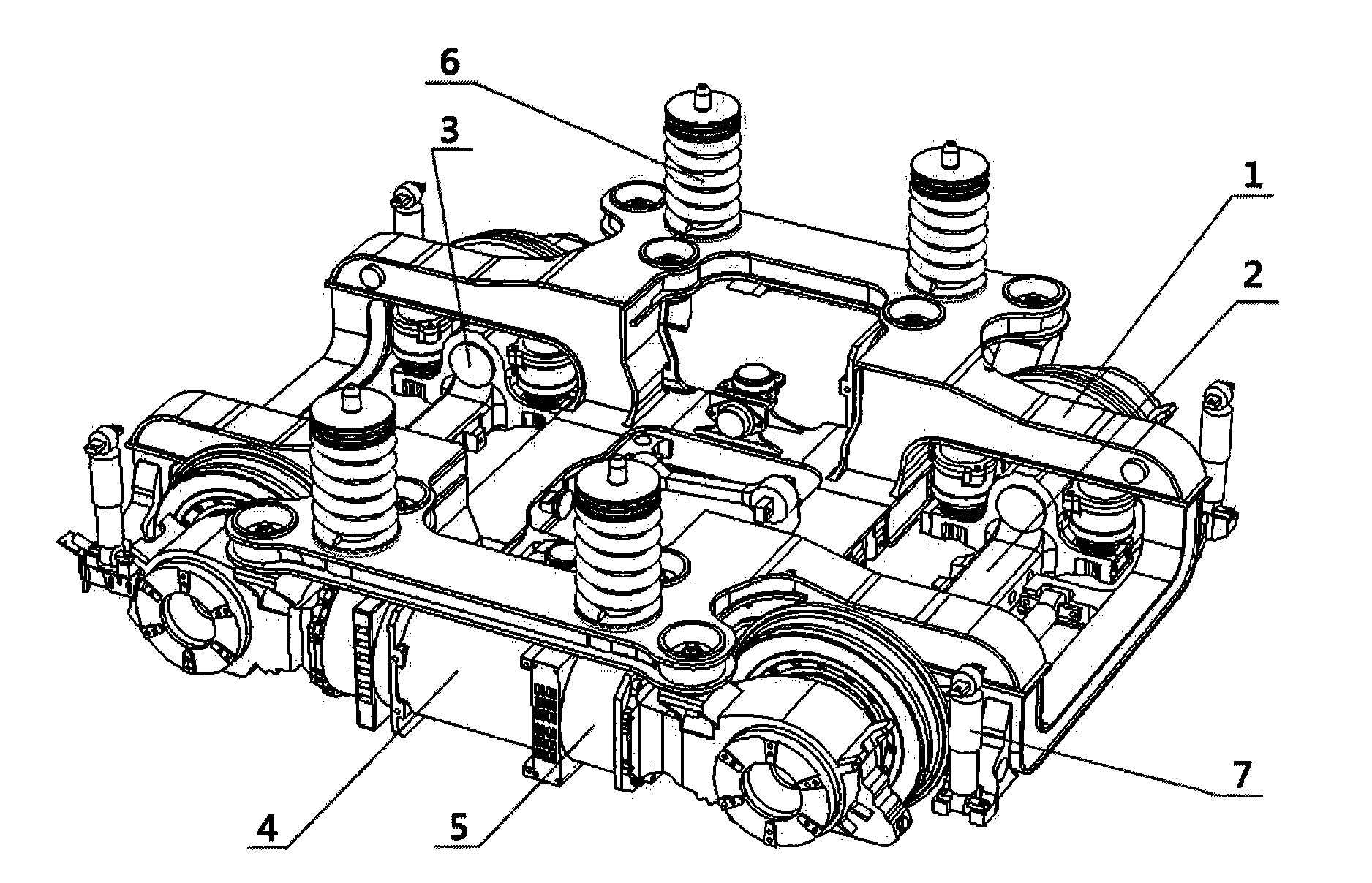

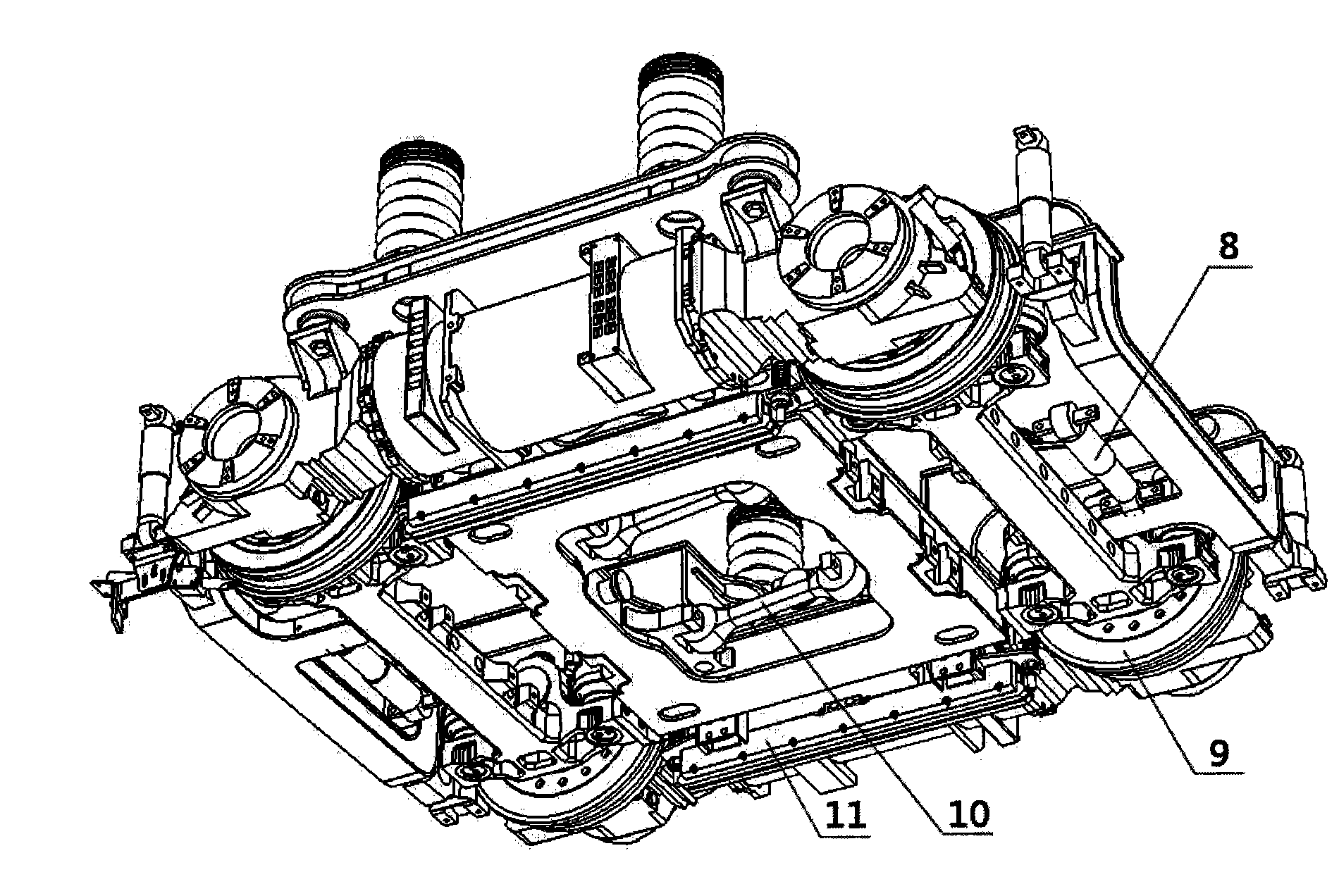

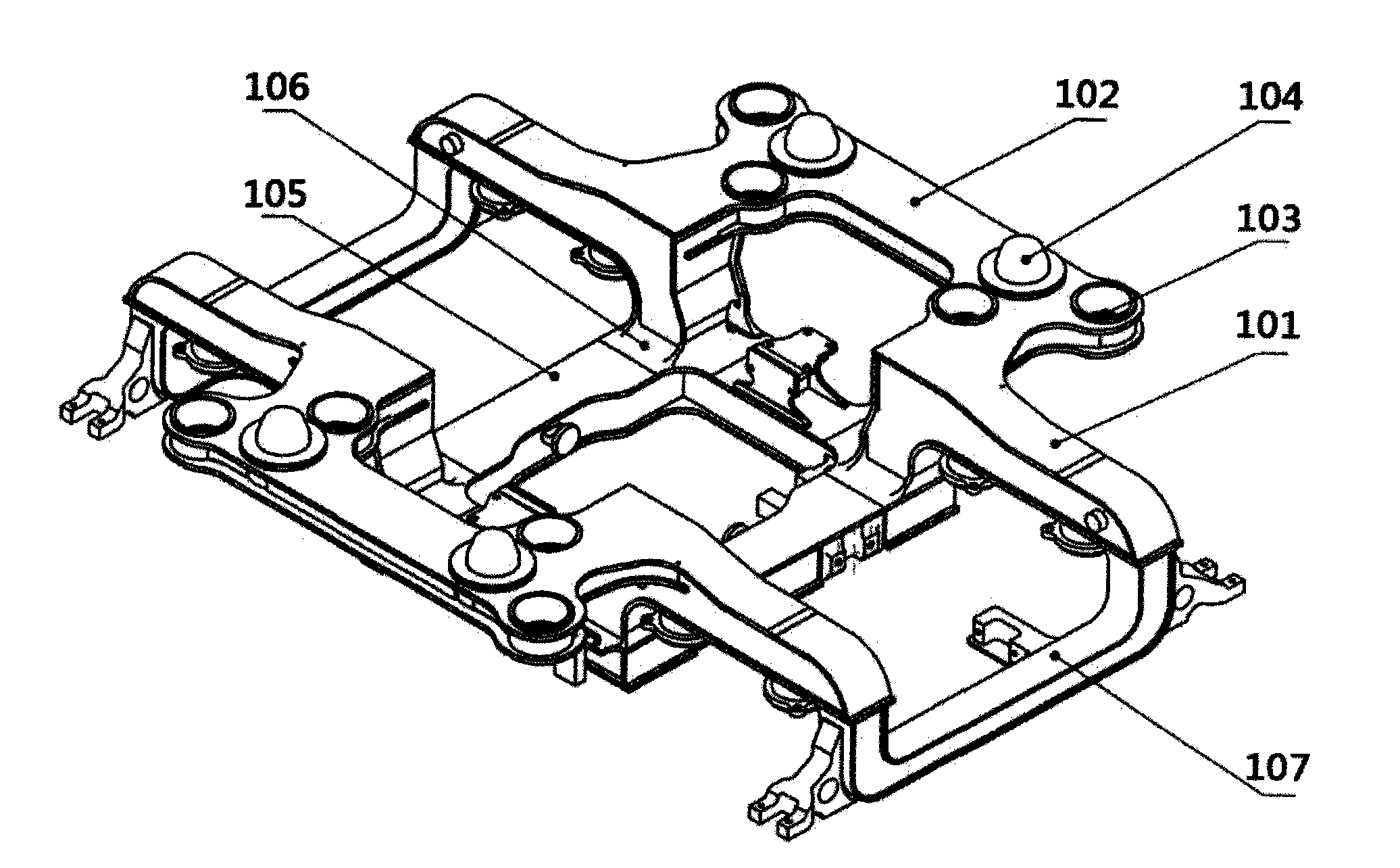

[0022] refer to figure 1 , figure 2 , the bogie of the present invention is composed of the following parts: a frame composed of side beams, cross beams and end beams welded together to form 1; axle bridges to form 2; short shaft 3; driven by a motor and a gear box through a coupling transmission Device 4; hydraulic brake unit 5 integrated with traction motor; secondary suspension system composition 6; secondary vertical vibration damping device 7; secondary lateral vibration damping device 8; elastic wheel 9 with vibration and noise reduction effects; Parallel double tie rod traction system 10; advanced magnetic track braking system 11. The frame composition is the basis for assembling other parts, and is one of the key components to realize the lowering of the car body floor; the short shaft 3 is assembled on the axle bridge composition 2, and is one of the key parts for changing the long shaft to a short shaft. The axle-bridge composition 2 is assembled with the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com