Light rail transport system for bulk materials

a technology for light rail and bulk materials, applied in transportation and packaging, rope railways, ways, etc., can solve the problems of high maintenance cost, high noise of highway trucks, and not very popular with the public, and achieve smooth rotational transition, high wear environment, and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

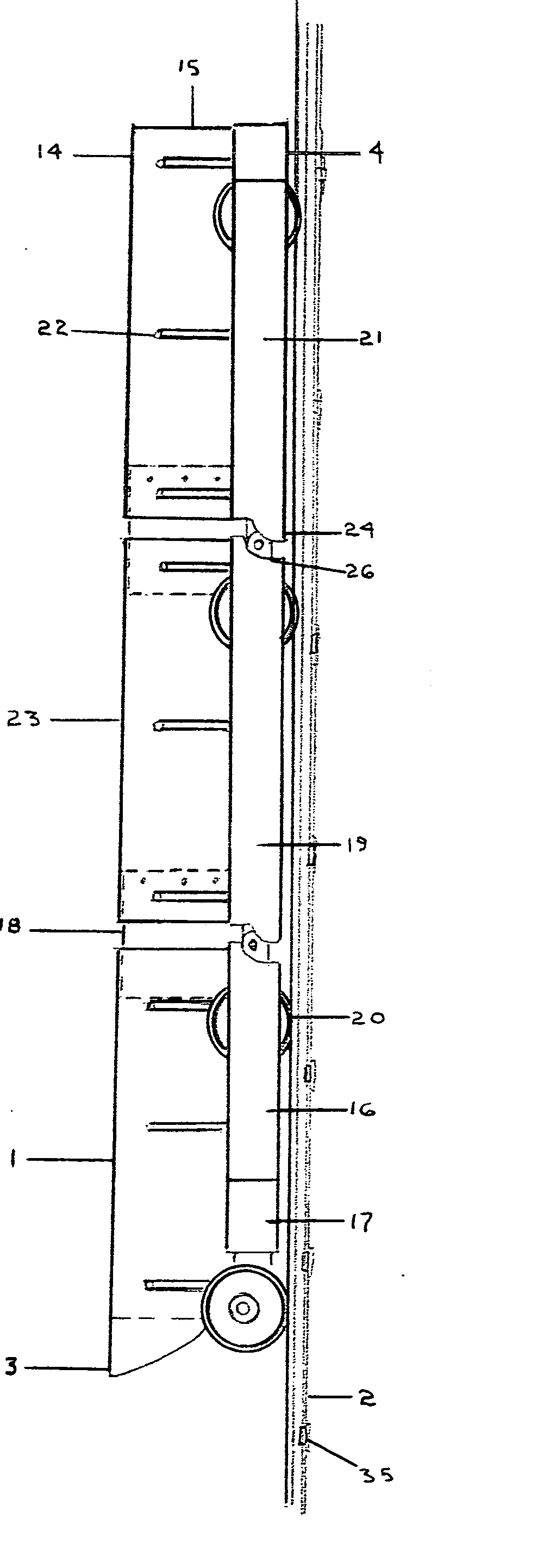

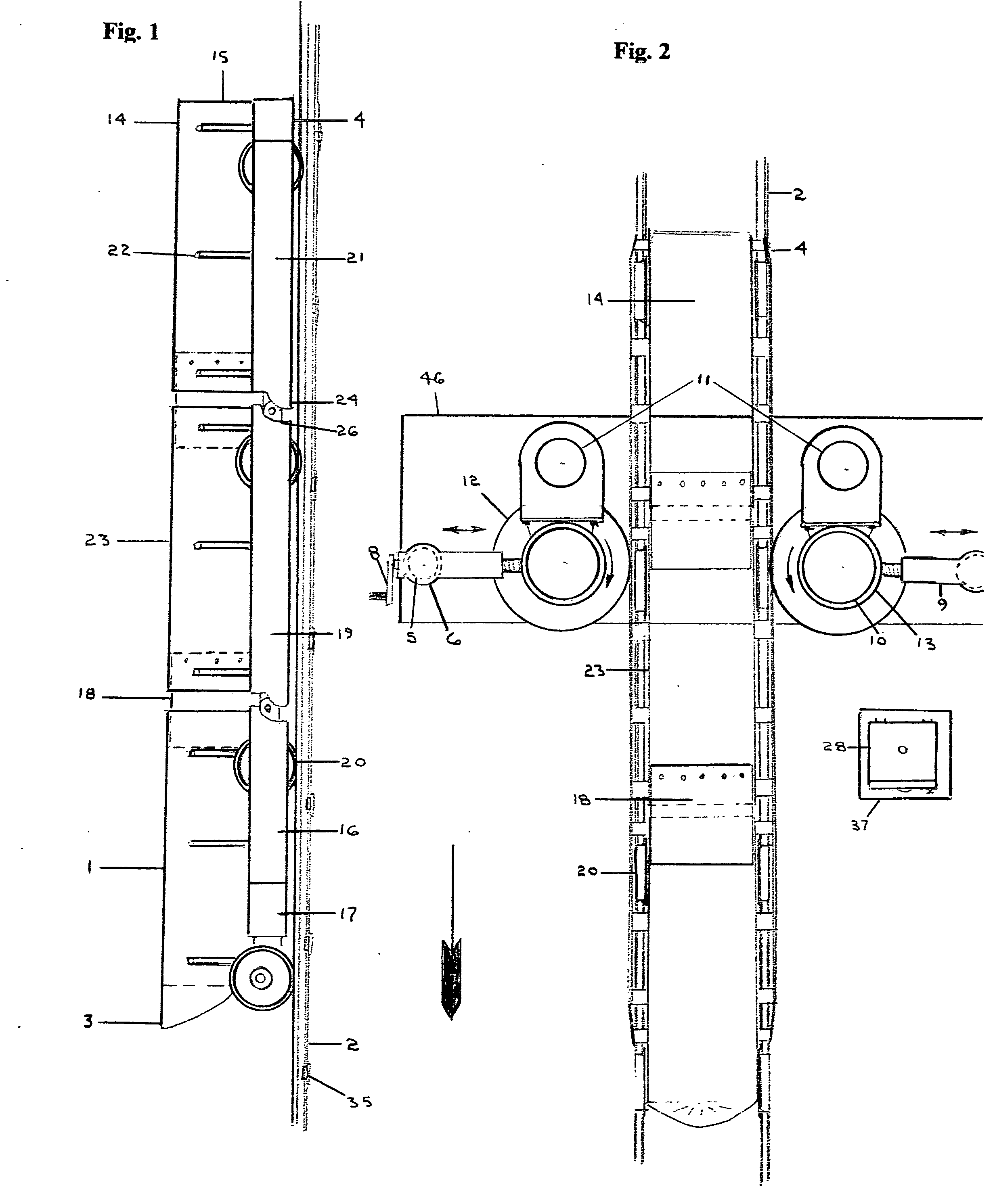

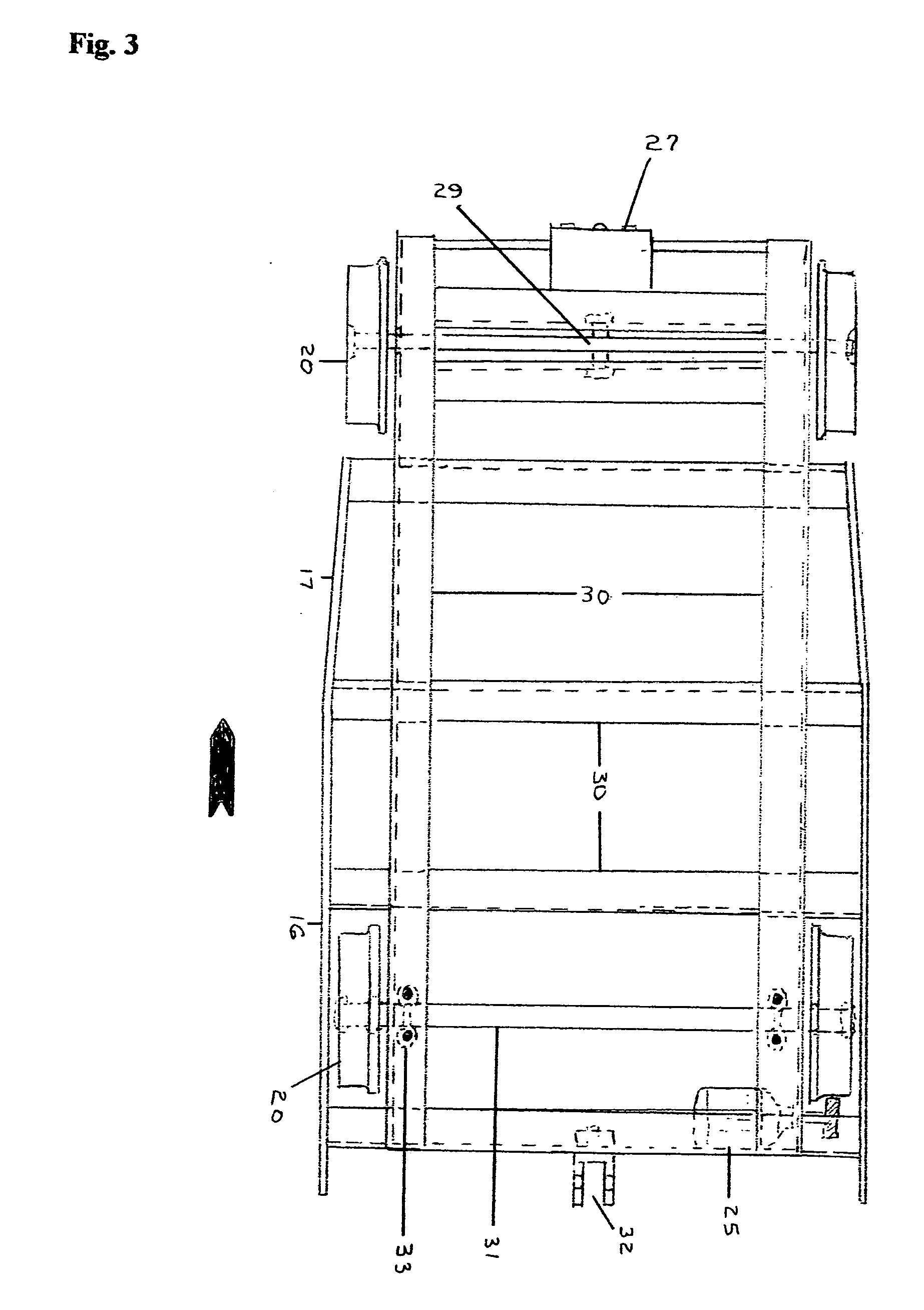

[0055]FIGS. 1-10 illustrate the invention but with regard to the reverence numerals used therein, the following index is presented to facilitate a better understanding of the numbering system used throughout all the figures.

1lead car trough2light rail track3front car discharge chute4rear car drive plate taper5support post for screw-jack6rotational cap for screw-jack7vertical post support brackets8screw-jack mechanicalcontrol handle9screw-jack housing10drive electric motor11pivot post for drive unit12drive tire13drive gear reducer14trough rear car15end plate rear car16front car main drive plate17front car drive plate taper18flexible sealing flap19intermediate cars drive plates20flanged wheel21rear car drive plate22car troughs support saddles23intermediate car trough24drive plate for rotation front25front car system generator26drive plate for rotation rear27safety system alarm pack28control box for A / C inverterfront car29front axle lead car pivot30car frame angle iron supportpin-twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com