Construction method of monolithic road-bed in rail tunnel

A technology of integral ballast bed and rail transportation, applied in the direction of track, laying track, track maintenance, etc., can solve the problems affecting the appearance quality of the overall ballast bed, the influence of the geometric dimension of the rail row, and the human quality accident, so as to improve the construction quality and reduce the construction process. , Improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] , construction technology

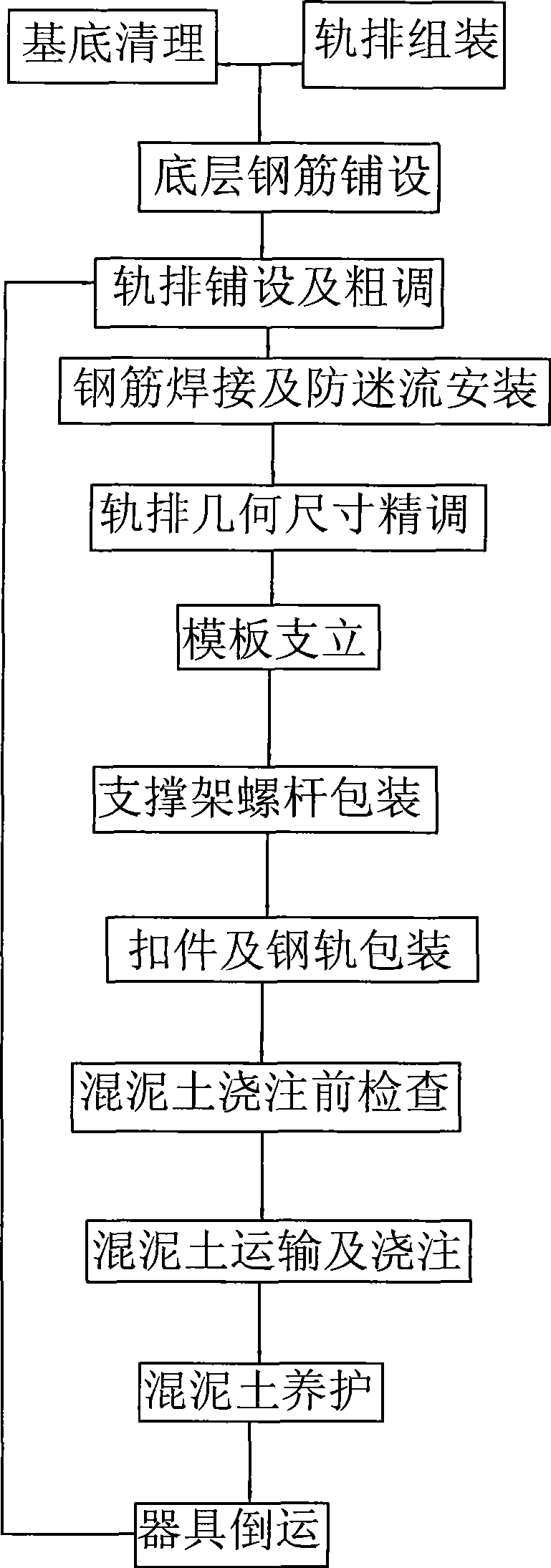

[0018] Such as figure 1 --- Construction process flow chart. The main construction process of the "support frame method" construction includes construction preparation, rail row assembly, base cleaning, bottom steel bar laying, rail row laying, rail row erection, steel bar binding and welding, formwork support, concrete pouring, and concrete curing.

[0019] , construction preparation

[0020] Due to the narrow construction site in the subway tunnel and the numerous construction procedures of the overall ballast bed, adequate preparation and reasonable organization of personnel and procedures are required in terms of construction preparation and construction organization, so as to avoid cross-operation interference and affect construction quality and project progress.

[0021] 1. Design and process construction equipment that matches this construction method.

[0022] 2. Purchase construction materials matching the corresponding constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com