Device and method for railway heavy type turnout multi-point-switch synchronous traction and control

A technology of switch machines and turnouts, which is applied in the direction of railway signals, railway car body parts, electrical equipment for manipulating turnouts or line breakers, etc. It can solve the problems of safety impact, poor scalability and maintainability, and achieve Improve safety, facilitate multi-machine traction, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

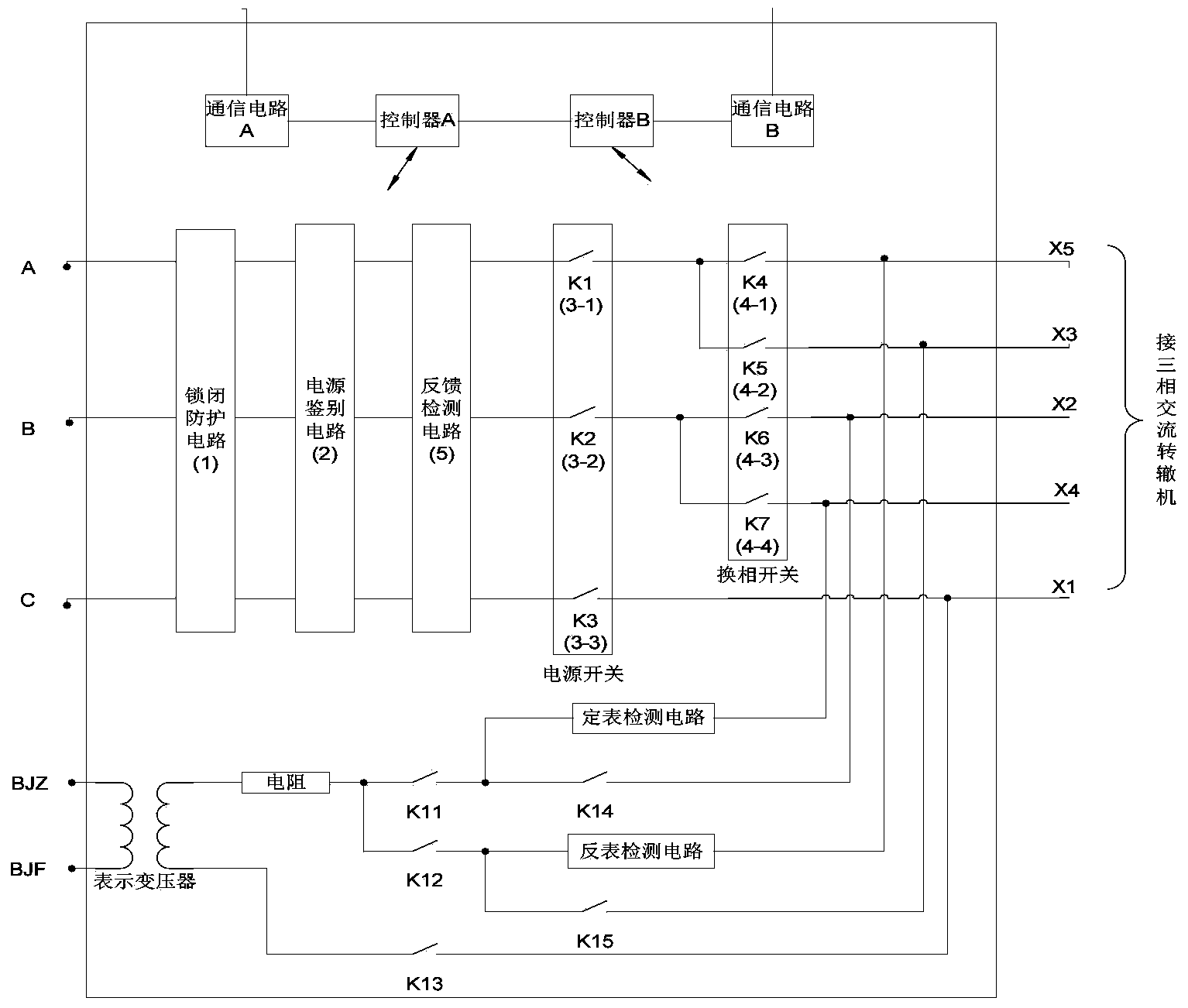

[0023] Example 1: see image 3 , a synchronous traction control device for multiple switch machines of railway heavy-duty turnouts, including a phase A power line connected to a power identification circuit 2 and a feedback detection circuit 5 through a locking protection circuit 1, and its output terminal is connected through a power switch K 1 3-1, with reversing switch K 4 4-1 X connected to the switch machine 5 , through the power switch K 1 3, with reversing switch K 5 4-2 X connected to the switch machine 3 ; The B-phase power line is connected with the power identification circuit 2 and the feedback detection circuit 5 through the locking protection circuit 1, and its output terminal is connected through the power switch K 2 3-2, with reversing switch K 6 4-2 X connected to the switch machine 2 , through the power switch K 2 3-1, with reversing switch K 7 4-2 X connected to the switch machine 4 ; The C-phase power line is connected with the power identification...

Embodiment 2

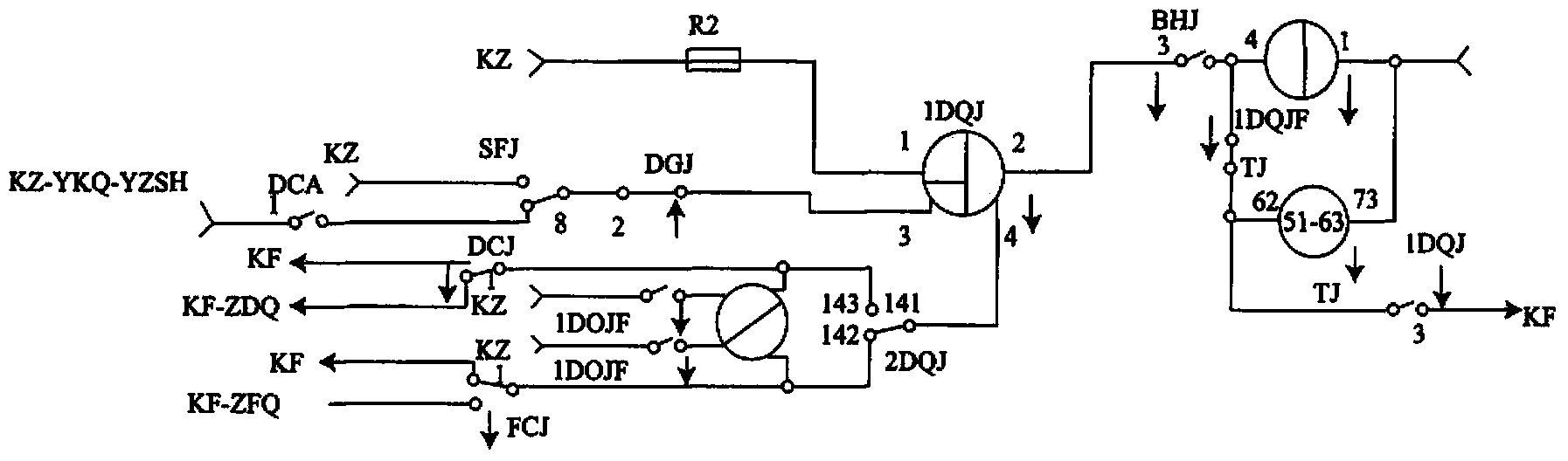

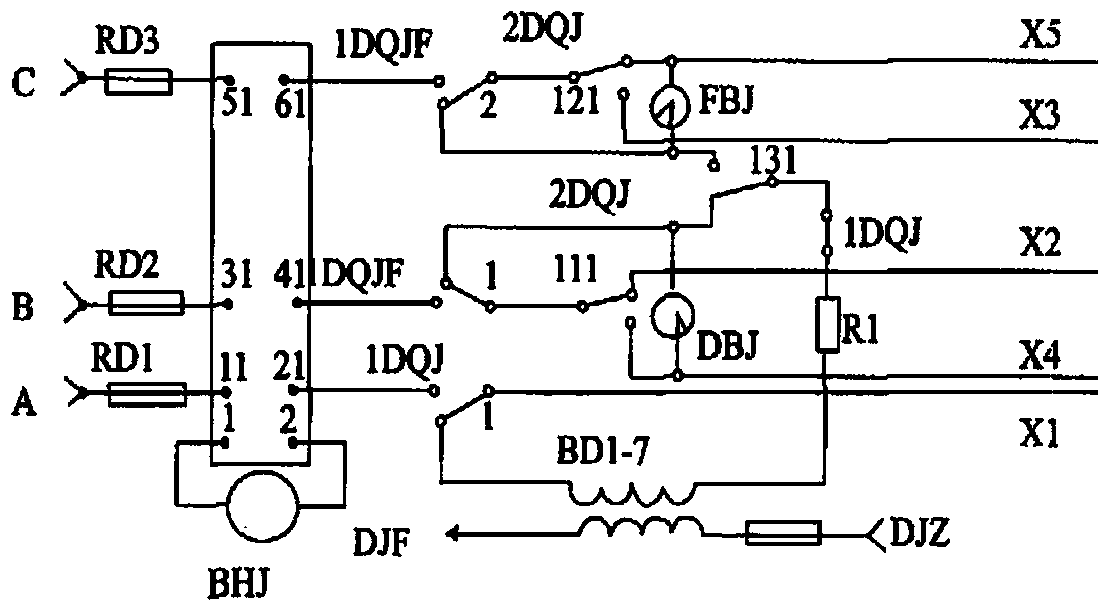

[0030]Embodiment 2: The synchronous traction control device for multiple point machines of railway heavy-duty turnouts, including the execution logic of the software part, the ZBHJ logic circuit and the QDJ logic circuit of the three-phase AC five-wire turnout control circuit for multi-machine traction.

[0031] See Figure 4 , ZBHJ is the general relay of the BHJ protection relays of multiple switch machines. In the figure, 1BHJ-nBHJ are the protection relays of the first and nth switch machines respectively. When the switch does not rotate, ZBHJ falls. After all the switch machines are started, the ZBHJ is sucked up, and after all the switch machines are switched, the ZBHJ falls.

[0032] See Figure 5 , QDJ is usually in the suction state, when the inconsistency time of the switch machine in the switch exceeds the slow release time, QDJ will fall. When the action of the switch machine is inconsistent, it plays the role of cutting off the power supply.

Embodiment 3

[0033] Embodiment 3: a method for synchronous traction control of multiple switch machines for railway heavy-duty turnouts, its main feature is to include the following steps: see Figure 6

[0034] (1) Device initialization and self-test;

[0035] (2) Check whether the device is faulty, if it is faulty, reverse to safety, if there is no fault, check whether the command has been received;

[0036] (3) Use the communication circuit to receive commands from the interlocking system, including turnout control, turnout locking, power cut off when multiple switch machines are not synchronized, and the sequence number of the switch start, and calculate the sequence number based on the sequence number Action delay time of the switch;

[0037] (4) Check whether the communication circuits A and B have received the above commands, if not, execute the detection signal, first close K11, K13 and K14, check whether there is a signal through the fixed meter detection circuit, if so, set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com