Arcuated steel rail beam and manufacturing method thereof

A manufacturing method and technology of steel track beams, applied in the direction of tracks, roads, bridges, etc., can solve the problems that track beams cannot be used for free and are not suitable for ride-on light rail trains, and achieve the effect of solving the deformation problem of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

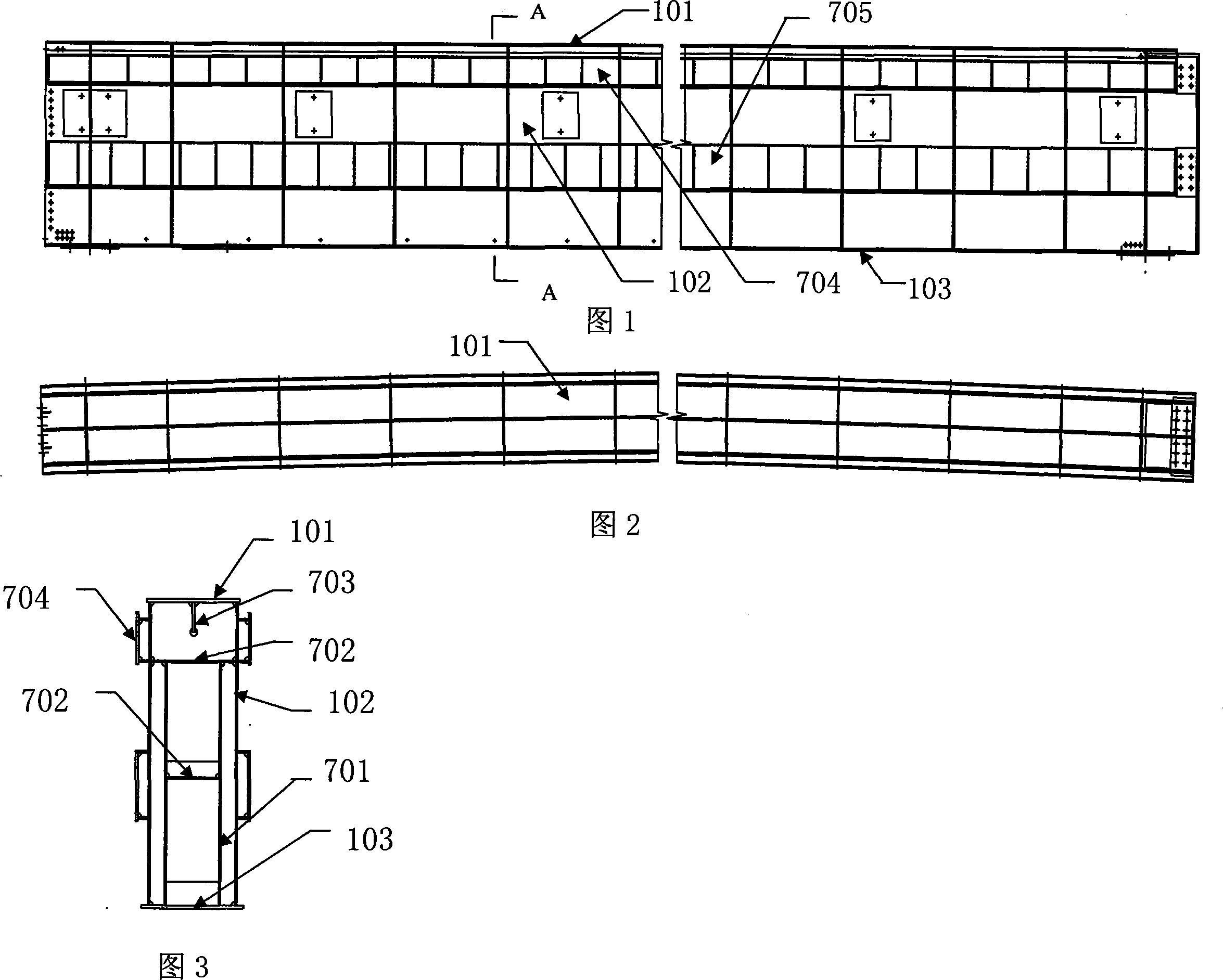

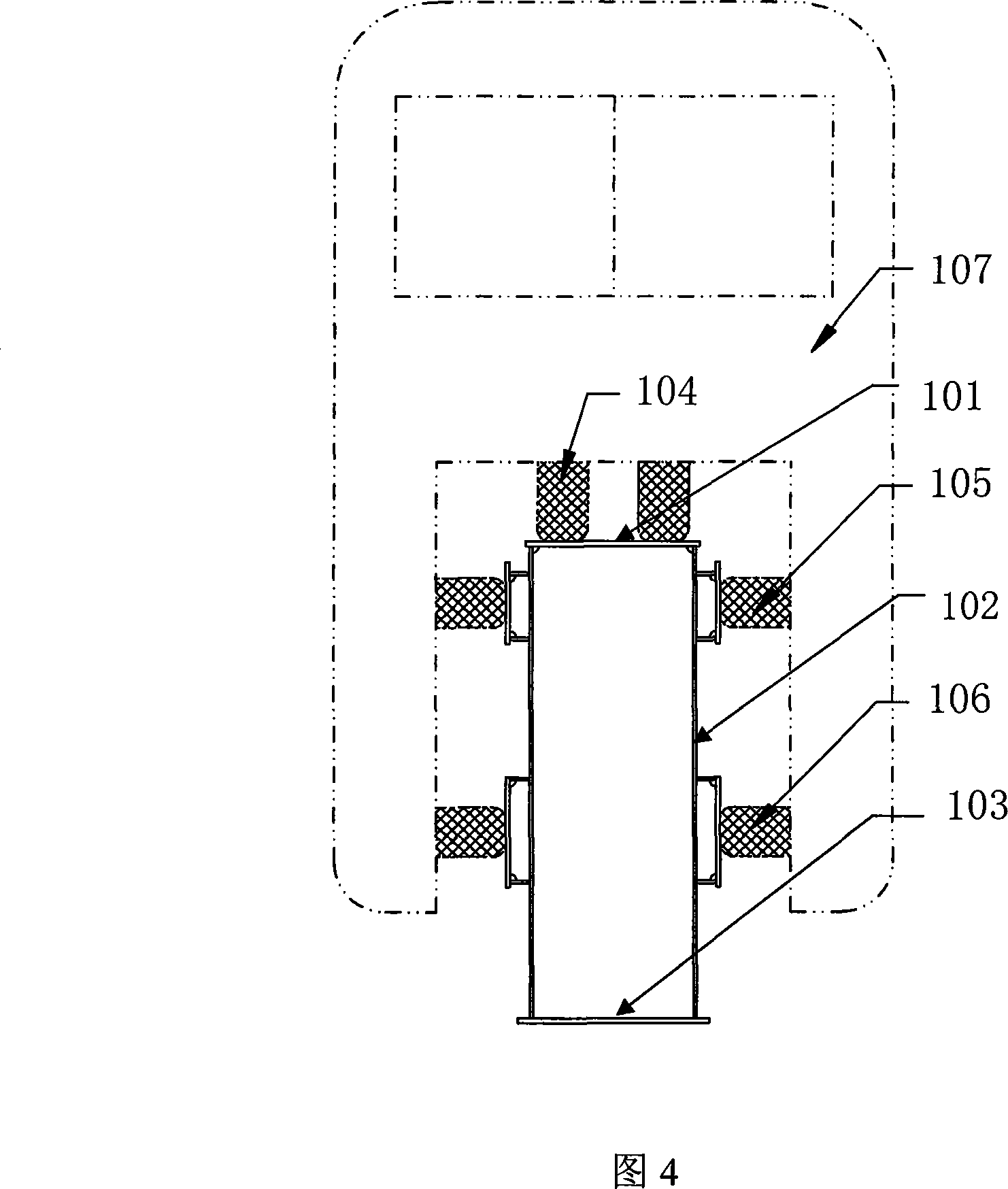

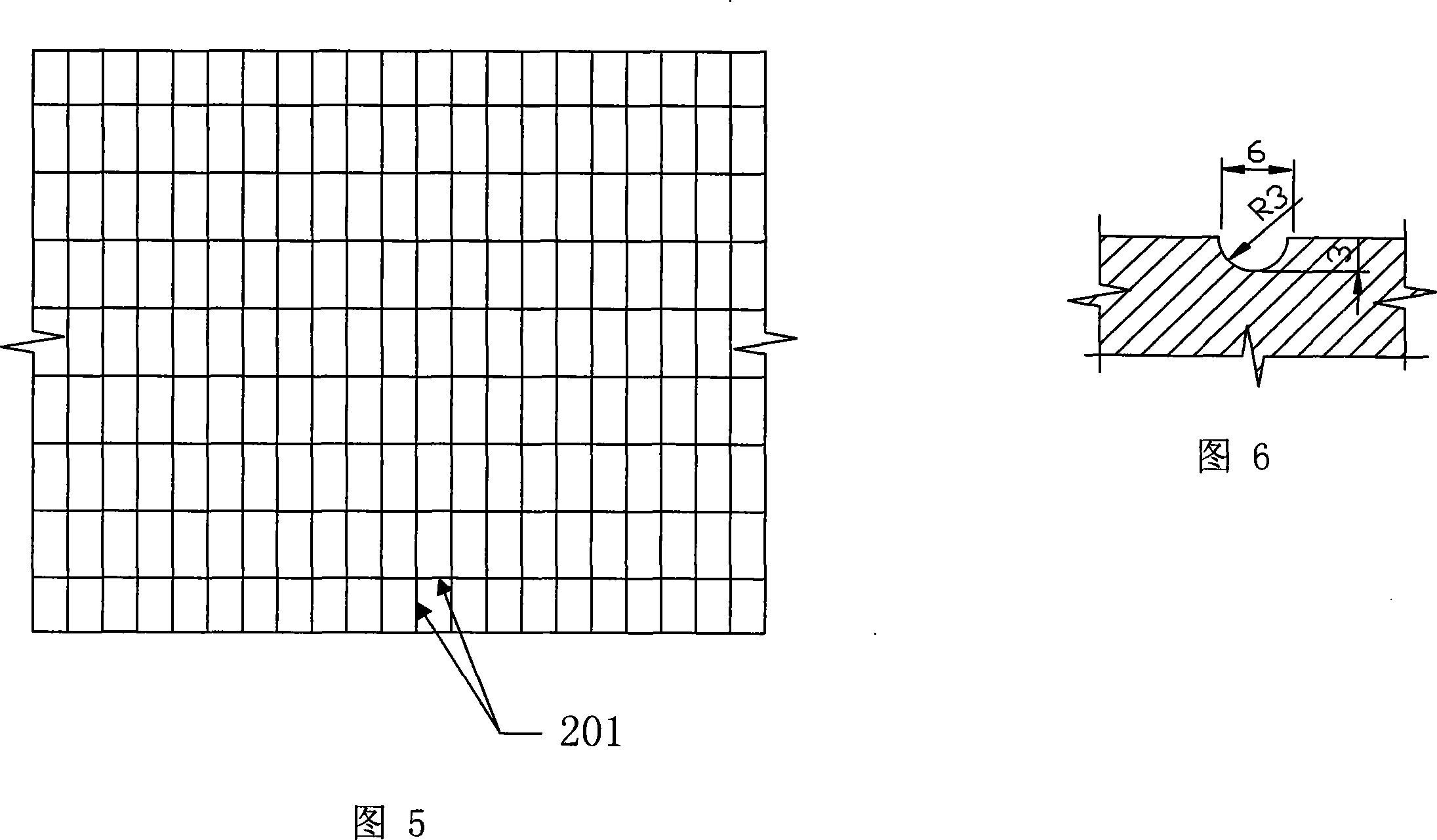

[0021] As shown in Fig. 1, Fig. 2 and Fig. 3, an arc-shaped steel track beam is composed of an upper cover plate 101, two opposite webs 102 and a lower cover plate 103 to form a box structure; the box structure is equipped with The upper cover plate 101 has transverse ribs 702 parallel to it, and longitudinal ribs 701 parallel to the web 102 . In addition, a longitudinal rib 703 is provided inside the upper cover 101 . Referring to Fig. 4, the outside of two webs 102 is symmetrically provided with the п-shaped guide beam 704 and the stabilizing beam 705 for cooperating with the light rail guide wheel 105 and the stabilizing wheel 106, and the guiding beam 704 and the stabilizing beam 705 are all made of top plate, web and rib The board is combined, and the deformation correction is made after welding. This arc-shaped steel track beam is mainly used for riding light rail trains. The light rail head and carriage 107 can safely walk on the steel track beam by means of two runnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com