Concrete base sound absorption material for road sound screen and method of manufacturing the same

A sound barrier and sound-absorbing technology, applied in applications, household appliances, ceramic products, etc., can solve problems such as economic losses, low sound absorption efficiency, and restrictions on the large-scale and extensive application of cement-based porous sound-absorbing materials, and achieve technical and economical results. Obvious benefits, low cost, and significant environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

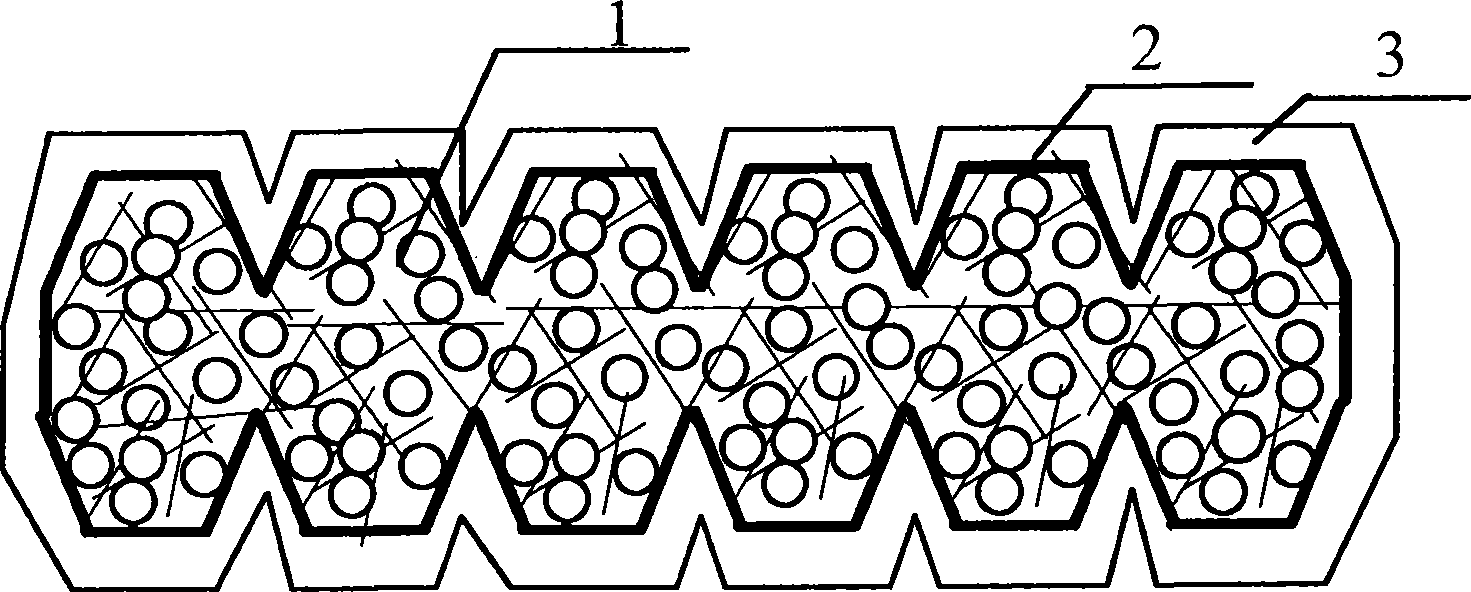

Image

Examples

Embodiment 1

[0027] Portland cement 20.3

[0028] Fly ash 5.0%

[0029] Ceramsite 34.8%

[0030] Sand 39.2%

[0031] Foaming agent 0.013%

[0032] Water reducer 0.10%

[0033] Fiber 0.46%

[0034] The above components were prepared according to the aforementioned process to obtain a cement-based sound-absorbing material, and its performance was measured as follows: compressive strength (7 days) 12.5MPa, average sound absorption coefficient 0.37, density 1194Kg / m 3

Embodiment 2

[0036] Portland cement 29.3%

[0037] Fly Ash 7.3%

[0038] Ceramsite 50.2%

[0039] Expanded Perlite 11.9%

[0040] Foaming agent 0.019%

[0041] Water reducer 0.15%

[0042] Fiber 0.89%

[0043] The above components were prepared according to the aforementioned process to obtain a cement-based sound-absorbing material, and its properties were measured as follows: compressive strength (7 days) 6.2MPa, average sound absorption coefficient 0.48, density 680Kg / m 3

Embodiment 3

[0045] Portland cement 45.0%

[0046] Slag 0.1%

[0047] Ceramsite 53.6%

[0048] Foaming agent 0.02%

[0049] Water reducer 0.18%

[0050] Fiber 1.0%

[0051] The above components were prepared according to the aforementioned process to obtain a cement-based sound-absorbing material, and its properties were measured as follows: compressive strength (7 days) 3.2MPa, average sound absorption coefficient 0.50, density 554Kg / m 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com