Aerogel composite board and preparation method thereof

A technology of airgel and composite panels, which is applied in the direction of building components, layered products, buildings, etc., can solve the problems of high production cost, high cost, and inability to withstand high pressure, and achieve a wide range of applications, reduce costs, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

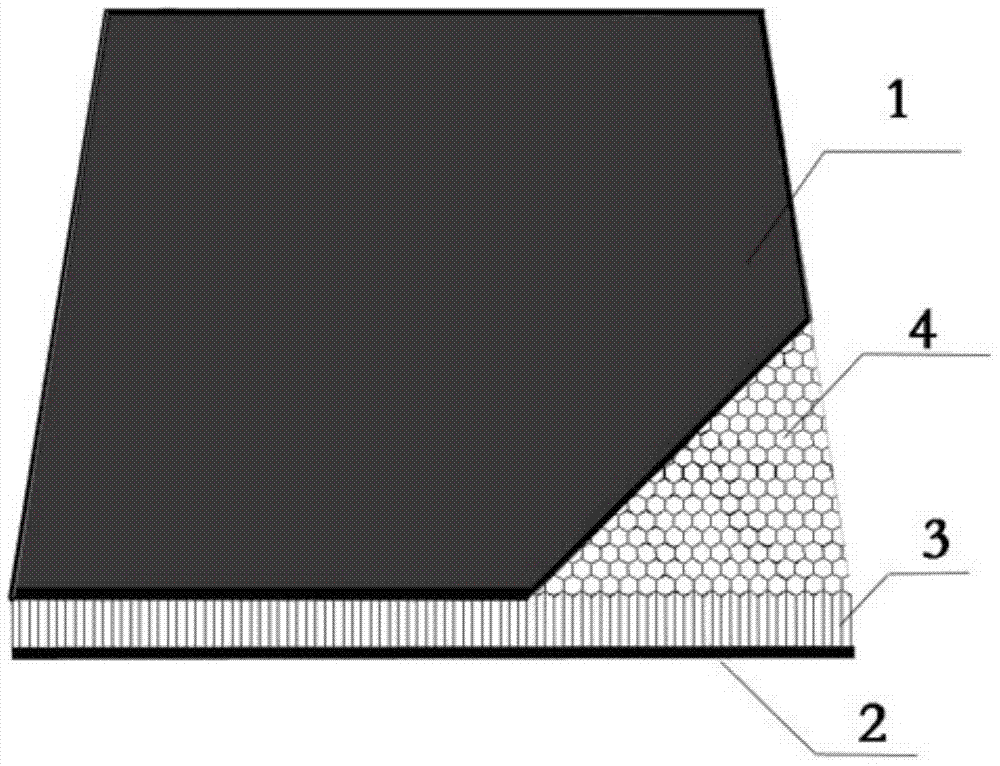

[0020] The panel is made of fluorocarbon baking varnish Lesier aluminum square plate; the bottom plate is made of calcium silicate pressure plate; the adhesive is made of epoxy resin structural glue; the honeycomb skeleton is made of flame-retardant PP honeycomb core; the silica airgel is made of water glass airgel.

[0021] The specific preparation method is as follows: first, apply epoxy resin structural adhesive on one side of the calcium silicate pressure plate and bond the PP honeycomb core; then fill the honeycomb with silica airgel; One side of the square board is also coated with epoxy resin structural glue, and pasted on the PP honeycomb core filled with silica airgel, and then the upper and lower boards are compacted.

[0022] Performance testing:

[0023] 1. Using GB / T10295-2008, the thermal conductivity of the composite board is detected to be 0.019 (W / m.k);

[0024] 2. The national standard GB8624-2012 for thermal insulation building materials is adopted, and th...

Embodiment 2

[0027] The panel is made of natural marble; the bottom plate is made of gypsum fiber pressure board; the adhesive is made of acrylic adhesive; the honeycomb skeleton is made of flame-retardant PC honeycomb core; the silica airgel is made of water glass airgel.

[0028] The preparation method is the same as in Example 1.

[0029] Performance testing:

[0030] 1. Using GB / T10295-2008, the thermal conductivity of the composite board is detected to be 0.01 (W / m.k);

[0031] 2. The national standard GB8624-2012 for thermal insulation building materials is adopted, and the composite board is tested to be Class A flame retardant;

[0032] 3. The detection of compressive strength is 2.3Mpa, and the detection of tensile strength is 1.6Mpa.

Embodiment 3

[0034] The panel is made of polyester fiberboard; the bottom plate is made of polyester fiberboard; the adhesive is made of polyurethane structural adhesive; the honeycomb skeleton is made of aluminum honeycomb core; the silica airgel is made of silica sol aerogel.

[0035] The preparation method is the same as in Example 1.

[0036] Performance testing:

[0037] 1. Using GB / T10295-2008, the thermal conductivity of the composite board is detected to be 0.02 (W / m.k);

[0038] 2. Adopt the national standard GB8624-2012 for thermal insulation building materials, and test that the composite board is S1 class flame retardant;

[0039] 3. The detection of compressive strength is 2.0Mpa, and the detection of tensile strength is 1.6Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com