Reinforced concrete ribbed grid-like large floorslab and preparation method thereof

A reinforced concrete and well-shaped technology, which is applied to floors, building components, buildings, etc., can solve the problems of poor sound insulation, poor thermal insulation, increased man-hours and costs, and high formwork turnover costs, achieving fast construction progress, improved sound insulation, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

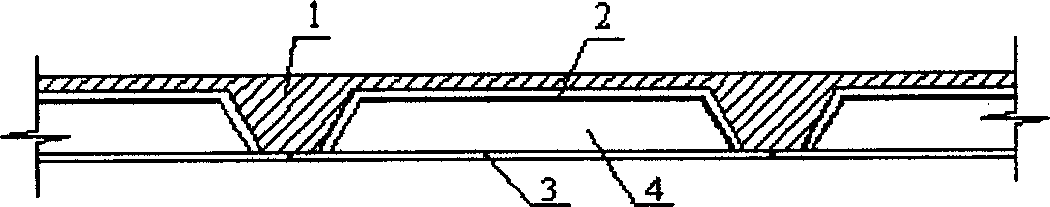

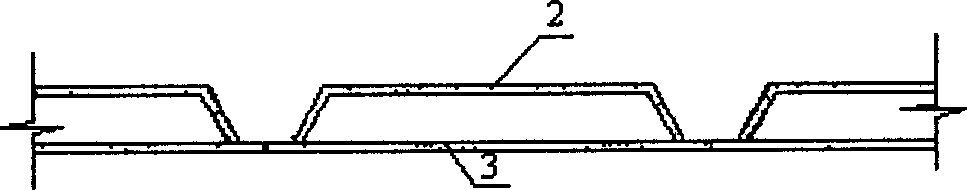

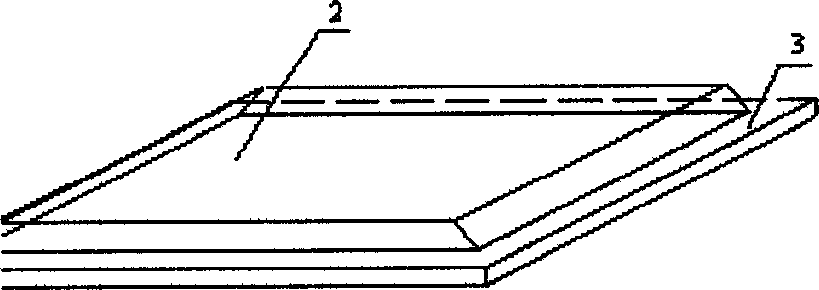

[0012] Embodiments of the present invention: as attached figure 1 As shown in or 2, it consists of a cast-in-place reinforced concrete cover (1) and a fabricated phosphogypsum board connected to the reinforced concrete cover (1), and the fabricated phosphogypsum board is embedded in the reinforced concrete cover in a grid pattern (1). The prefabricated phosphogypsum board is manufactured in a factory, and it consists of an upper arched side formwork (2) and a lower plate-type bottom formwork (3) made of phosphogypsum material. The side formwork (2) and the bottom formwork (3) are composed of Phosphogypsum is composed of a layer of glass fiber mesh cloth, and S-shaped hooks are pre-embedded, generally one every 450mm, which is convenient to connect with the reinforced concrete cover plate (1), and the side formwork (2) and the bottom formwork (3) are made as one , the side formwork (2)) is embedded in the reinforced concrete cover plate (1), the bottom formwork (3) is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com