Car door structure and noise insulation sheet

A technology for sound insulation panels and car doors, which is applied to doors, door leaves, windows/doors, etc. It can solve problems such as difficult installation and defective sound insulation effects, and achieve the effect of improving sound insulation effects and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

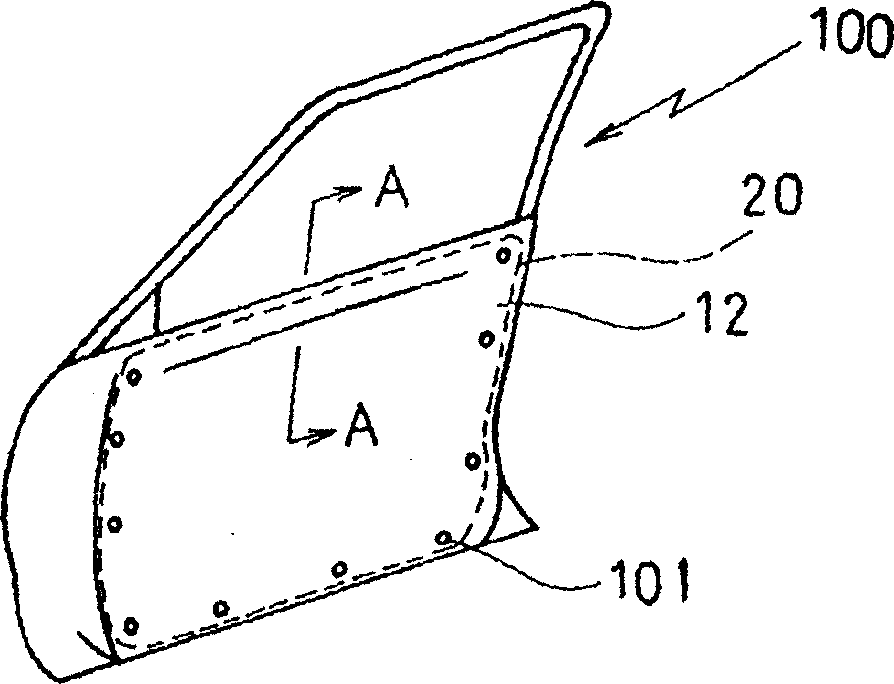

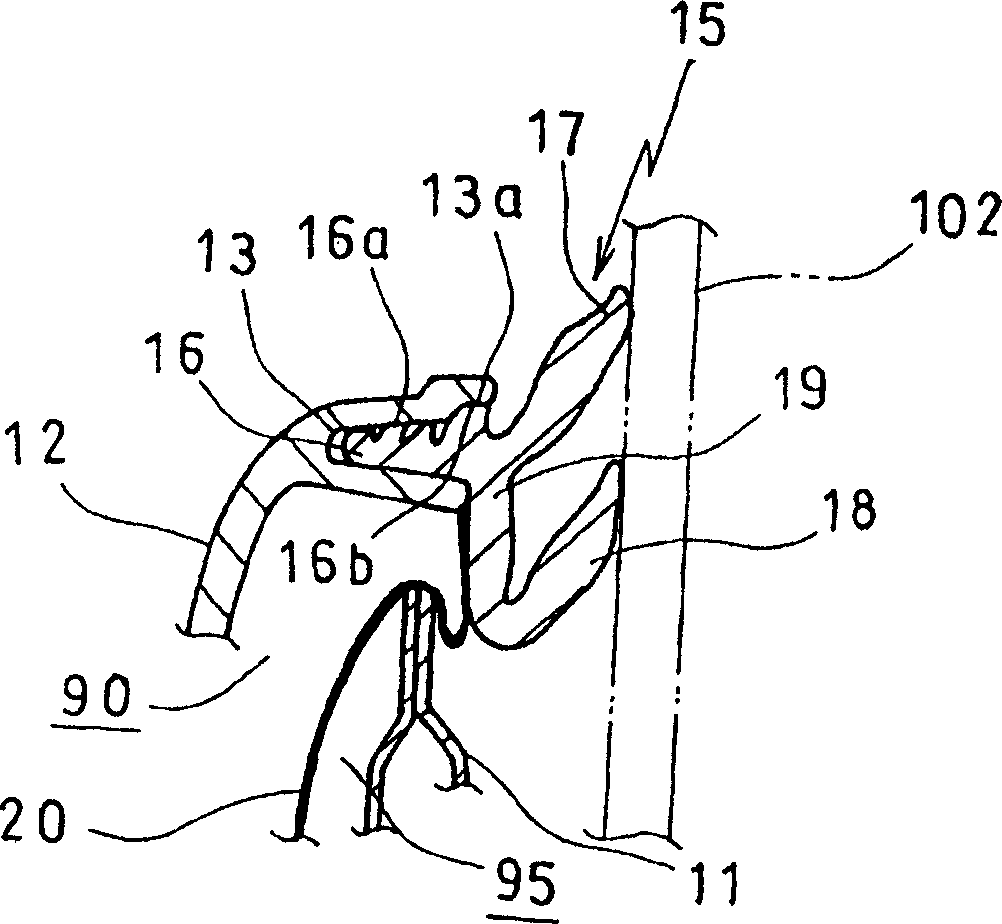

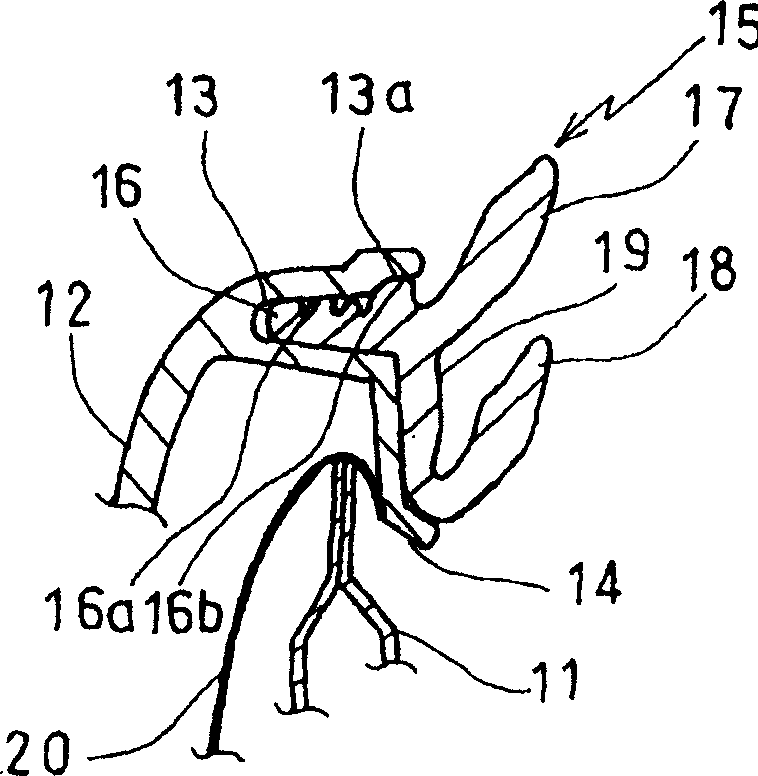

[0079] The following will refer to the appendix figure 1 and 2 The door structure in the first embodiment of the present invention will be described. attached figure 1 is a perspective view of a vehicle door structure in a first embodiment according to the present invention. attached figure 2 is attached figure 1 Enlarged cross-sectional view of line A-A in the middle.

[0080] The vehicle door structure includes a vehicle door inner panel 11 which constitutes a part of the vehicle door 100 and is located on the inner side of the waistline of the car body. A door inner liner 12 is mounted on the upper inner side of the door inner guard 11 . A weather strip 15 is mounted on the upper portion of the door liner 12 to form elastic contact with the door glass 10 .

[0081] The inner sealing strip 15 includes an attachment base 16 , a pair of sealing lips 17 , 18 and a support portion 19 . The sealing lip 17 is located above the sealing lip 18, and the sealing lips 17, 18 a...

no. 3 example

[0108] The following will refer to the appendix Figure 10 and 11 The door structure of the third embodiment of the present invention will be described. in the attached Figure 10 , the inner weather strip 15 is shown as a double-dot chain line, and the area positioning of the baffle 30 is shown as a diagonal line.

[0109] Compared with the second embodiment of the present invention described above, in this embodiment, the door lining 12 and the inner weather strip 15 are similar in shape, but the means for securing the upper part of the baffle 30 are different.

[0110] That is to say, the incoming edge Figure 8 The sectional view of the B-B line is shown (corresponding to the appendix in the first embodiment figure 2 ), when the legs 14 are not formed, the upper part of the sound insulation board 30 is fixed to the support part 19, and its structure is similar to that of the sound insulation board 20 in the second embodiment. However, unlike the second embodiment, th...

no. 4 example

[0114] as attached figure 2 As shown in the first embodiment of the present invention, there is a problem that the baffle 20 or its lower end protrudes from the door liner 12 when the baffle 20 is fixed by the re-end and hangs down.

[0115] In this case, the baffle 20 protrudes from the door lining 12, the overall look and feel of the car door will be damaged, and the sound insulation effect thereof will also be damaged.

[0116] Therefore, the object of the fourth embodiment of the present invention is to firmly fix the end of the baffle provided between the inner door panel and the door lining and to position the baffle so that it does not protrude from the door lining.

[0117] Refer to the attached Figure 12 and 13 , the fourth embodiment of the car door structure of the present invention will be described below. attached Figure 12 is a disassembled perspective view showing a car door structure according to a fourth embodiment of the present invention. attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com