External-hanging sound barrier for rail transit

A rail transit and plug-in technology, applied in construction, noise absorption devices, etc., can solve problems such as noise pollution in the surrounding environment, damage to the sound barrier, sound insulation loopholes in the sound barrier, etc., and achieve good streamlined appearance, stable performance, and avoid exposure to the sun Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

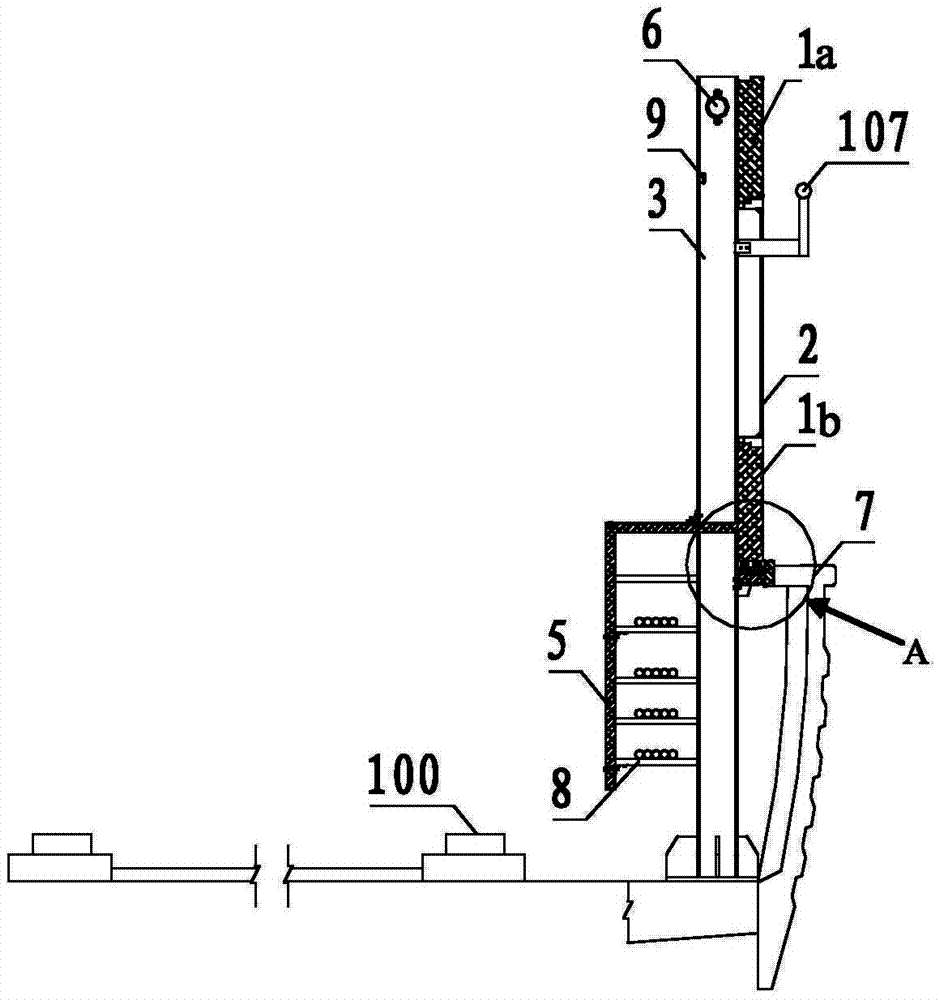

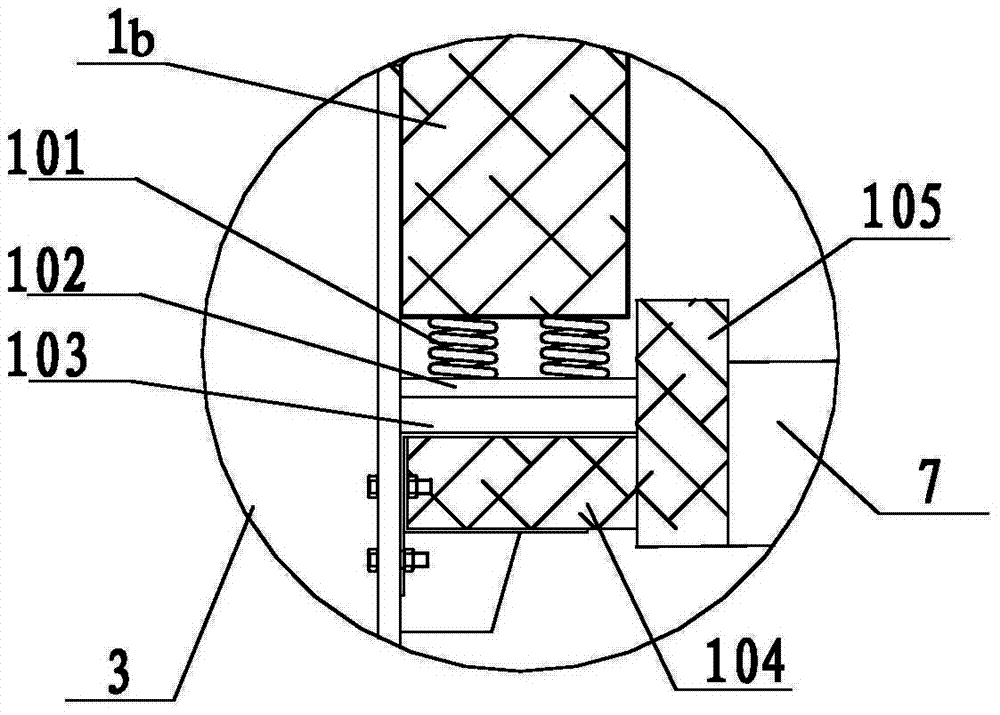

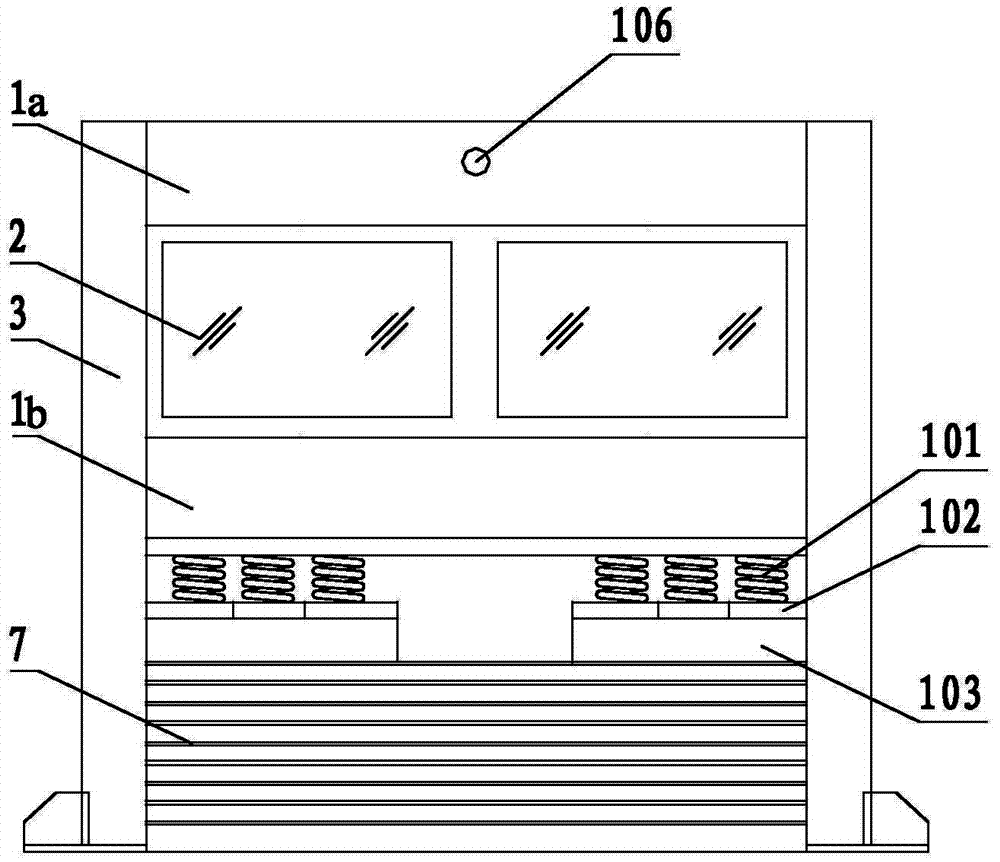

[0029] Such as figure 1 As shown, a rail transit external sound barrier of the present invention includes a plurality of steel columns 3 on one side of the track 100, and adjacent steel columns 3 are connected and fixed by supporting beams 6; when the steel columns are close to the track A cable bracket 8 is arranged on one side of the cable bracket 8, and the sunshade and sound-absorbing panel 5 is covered on the cable bracket 8. The sun-shading and sound-absorbing panel 5 covers the top and side surfaces of the cable bracket 8, and plays a protective role for the cables on the cable bracket 8. .

[0030] A guardrail 7 is provided on the side of the steel column 3 away from the track 100, and the suction and sound insulation scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com