Footing for sound-barrier walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Other objects, features and advantages of the invention will become apparent from a consideration of the following detailed description and the accompanying drawings.

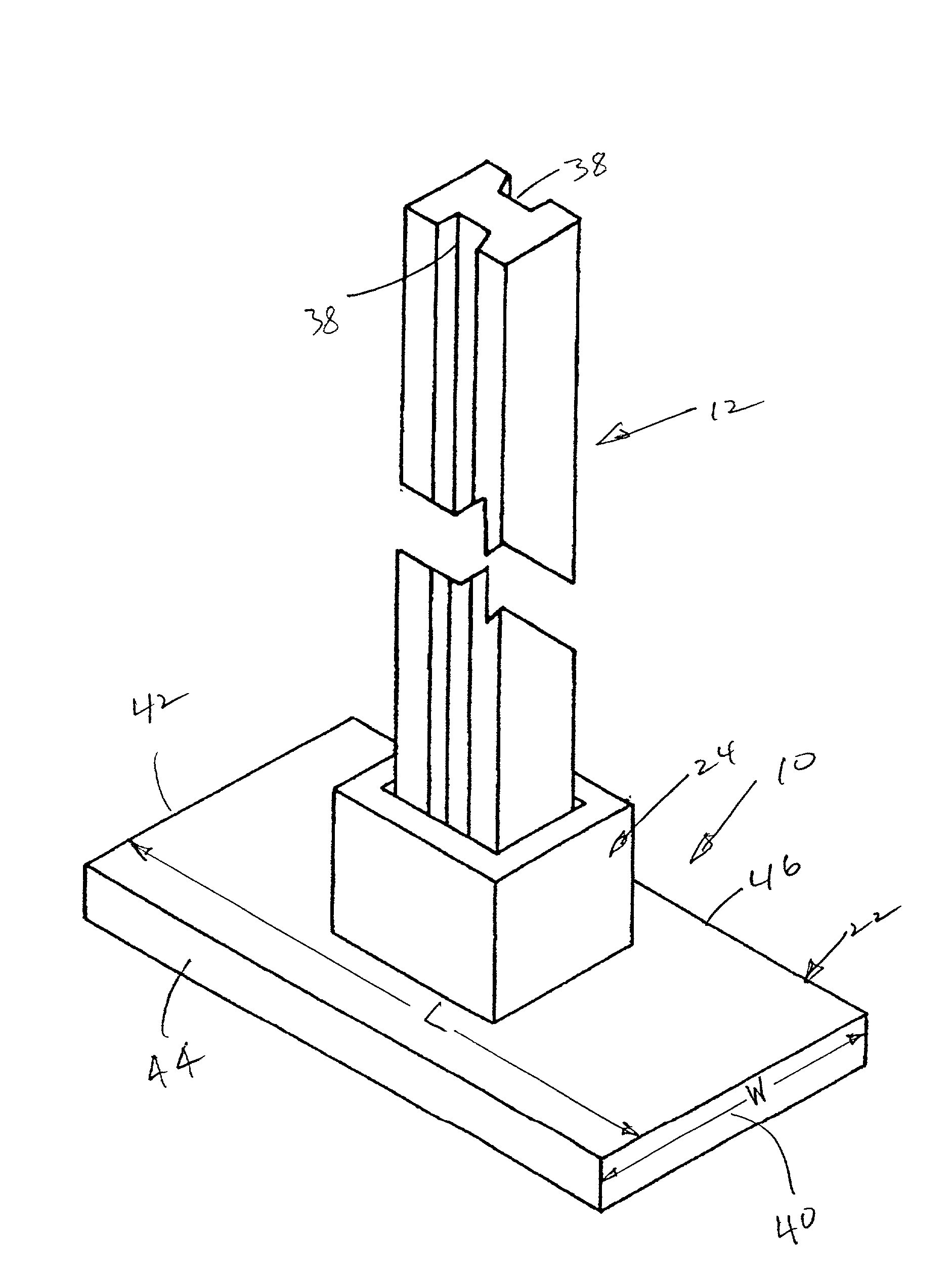

[0032] Shown in FIG. 1 is a sound-barrier wall 10 which is positioned adjacent to a roadway (not shown) to control noise generated at the roadway. Wall 10 is mounted in the ground G which can be uneven, or difficult to work in as is well known to those skilled in the art. Wall 10 generally includes stanchions 12 anchored in ground G to extend upwardly from the ground and which support sound-controlling panels, such as panel 14. Panels 14 can be formed in the manner described in the referenced patents; therefore, no discussion will be presented regarding the panels per se.

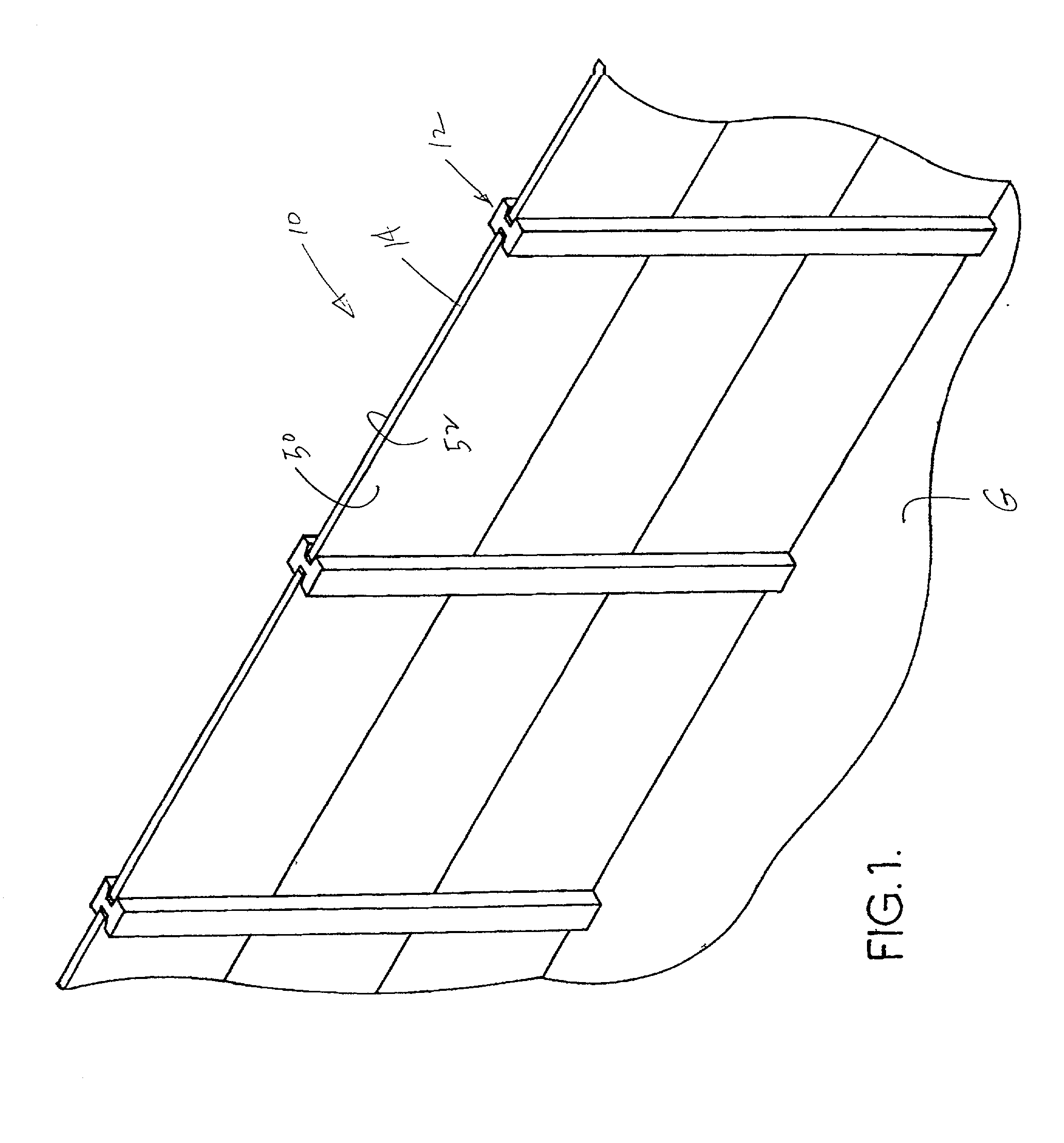

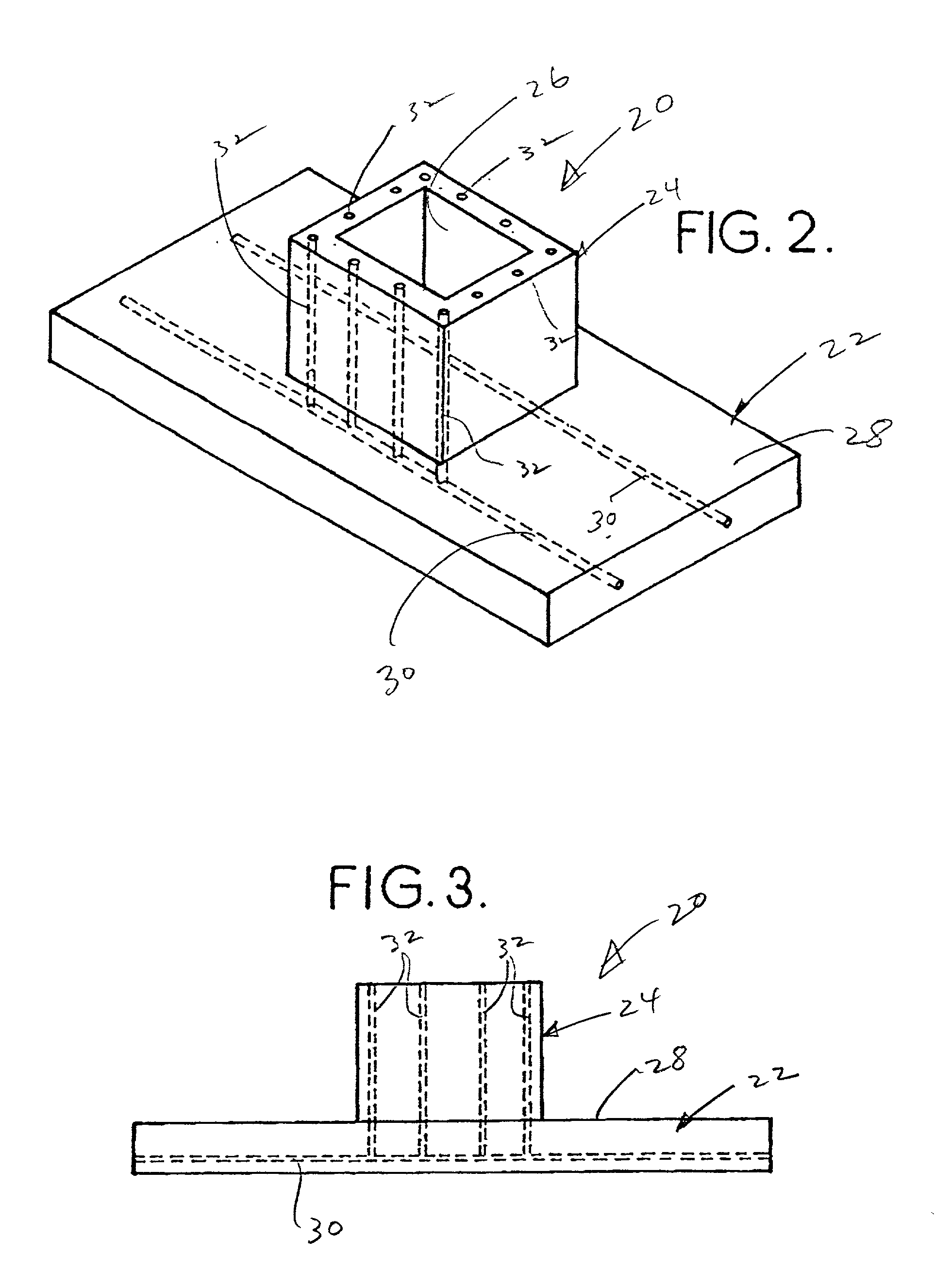

[0033] As discussed above, placing stanchions 12 in the ground can be a difficult process, especially if the ground is uneven or rocky. Accordingly, the present invention is directed to a footing that can be used in an effective and efficient man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com