Method for manufacturing light concrete composite wall plate, building plate and road sound barrier plate

A technology of lightweight concrete and composite wall panels, which is applied to building structures, building components, buildings, etc., and can solve problems such as the method of large lightweight concrete wall panels that have not been found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

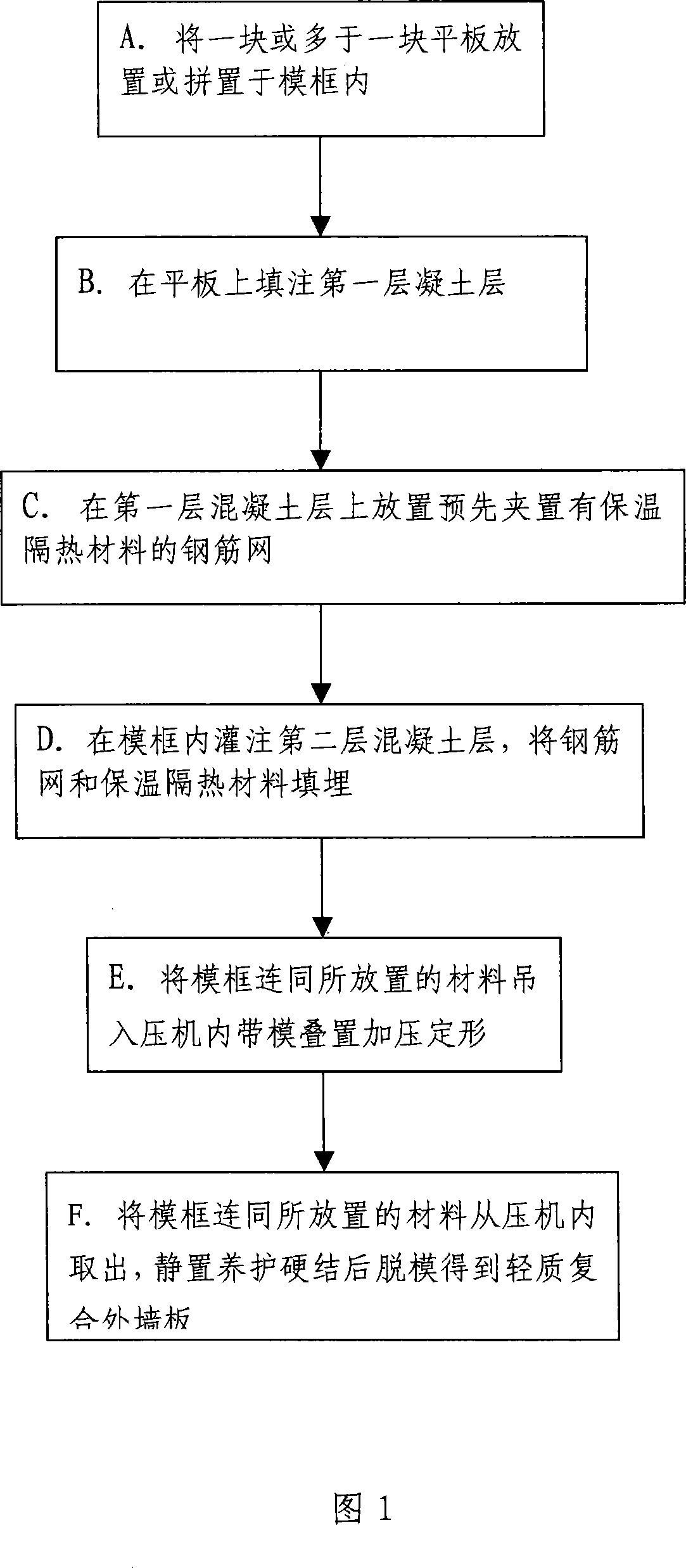

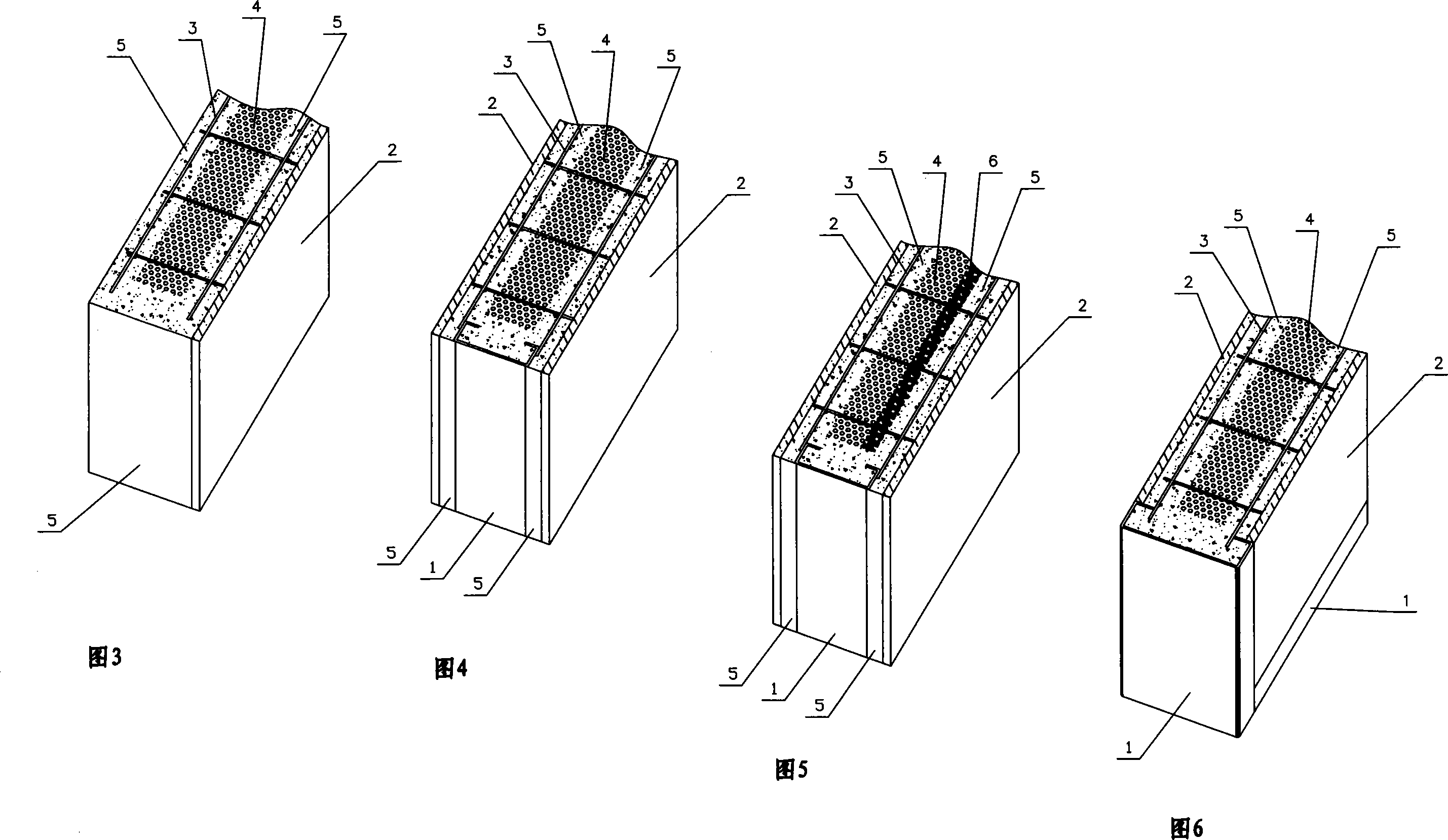

[0035] With reference to Fig. 1 and Fig. 3, Fig. 1 represents the production process flow of a kind of lightweight concrete composite wallboard of the present invention, and it carries out following process successively:

[0036] A. Put more than one cement slab into the mold frame. The cement slab used is glass fiber reinforced cement slab. The size of the mold frame depends on the specifications of the wallboard to be made. The cement slab

[0037] 2 It can be replaced by gypsum board, silicon-calcium board or steel mesh board.

[0038] B. Fill the first layer of concrete layer 5 on the cement slab 2. The concrete used in the concrete layer 5 is lightweight high-strength concrete, which is mixed with cement and filler, wherein the cement is Portland cement and sulfoaluminate Cement-like or aluminate-like cement, the filler is a single or a mixture of more than one of the following materials: sand, gravel, ceramsite, expanded perlite, polystyrene foamed particles, expanded ve...

Embodiment 2

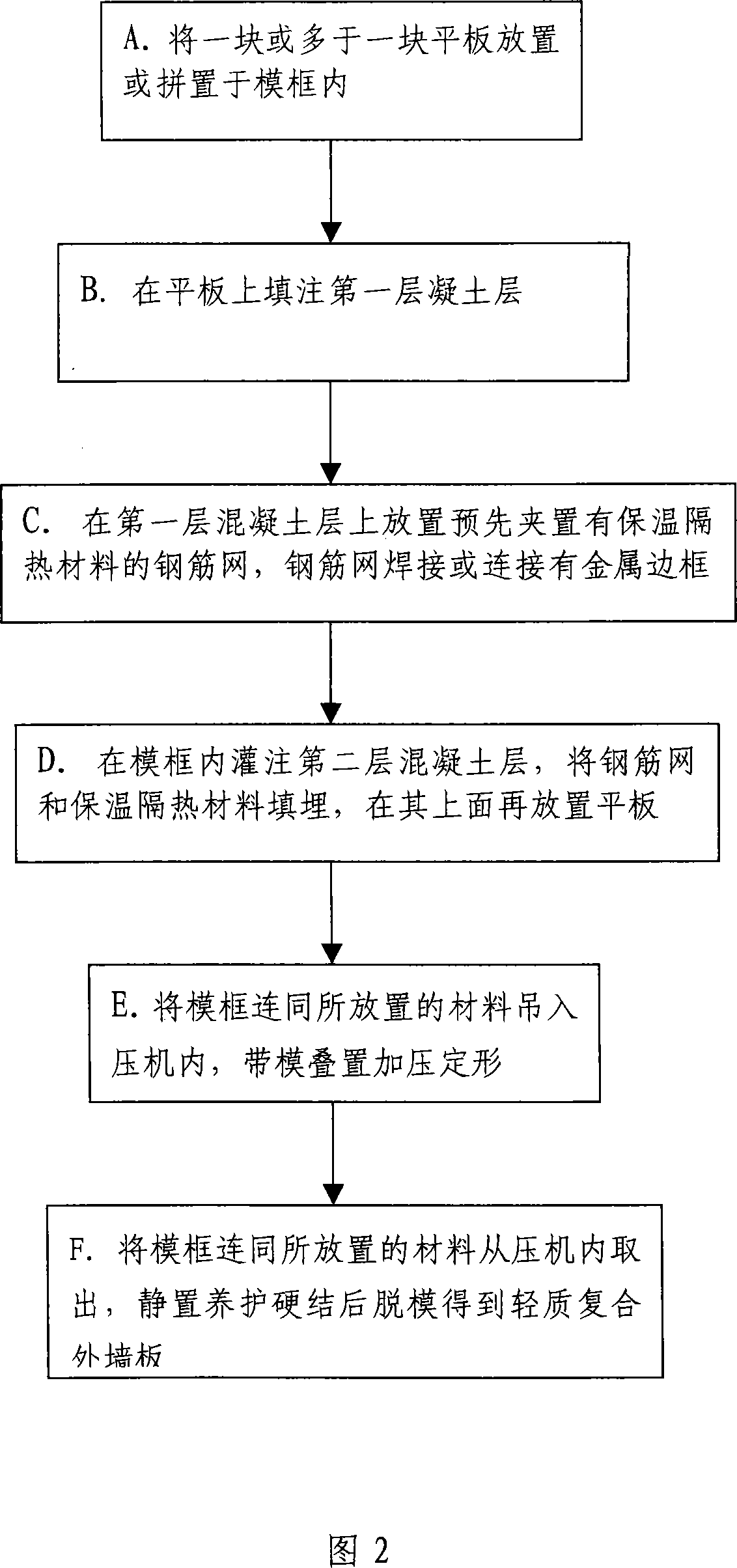

[0045] With reference to Fig. 2 and Fig. 4, Fig. 2 represents the production technological process of a kind of lightweight concrete composite wallboard of the present invention, and it carries out following process successively:

[0046] A. Put more than one cement slab 2 into the mold frame. The cement slab used is glass fiber reinforced cement slab. The size of the mold frame depends on the specifications of the wallboard to be made. The cement slab 2 can be gypsum board, calcium silicate board or stencil instead.

[0047] B. Fill the first layer of concrete layer 5 on the cement slab 2. The concrete used in the concrete layer 5 is lightweight high-strength concrete, which is mixed with cement and filler, wherein the cement is Portland cement and sulfoaluminate Cement-like or aluminate-like cement, the filler is a single or a mixture of more than one of the following materials: sand, gravel, ceramsite, expanded perlite, polystyrene foamed particles, expanded vermiculite, ci...

Embodiment 3

[0054] With reference to Fig. 5, the process of the present embodiment is identical with embodiment two (referring to Fig. 2), and material used is also roughly the same with embodiment one, difference is process:

[0055] C. The thermal insulation material 4 pre-clamped in the steel mesh 3 is combined with a fireproof material layer 6, and the fireproof material layer 6 is a refractory material such as mineral wool board, rock wool board, volcanic rock wool board or glass wool board.

[0056] The product structure of this embodiment is shown in Figure 5, and this wallboard is used in occasions with higher fire protection requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com