Hard polyvinyl chloride sound insulation barrier and manufacturing technique

A technology of rigid polyvinyl chloride and sound insulation barriers, applied in metal processing, household components, applications, etc., can solve the problems of the section being easily eroded by rain, overall strength decline, and heavy maintenance workload, and achieve beautiful colors and increased Anti-corrosion performance, maintenance-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

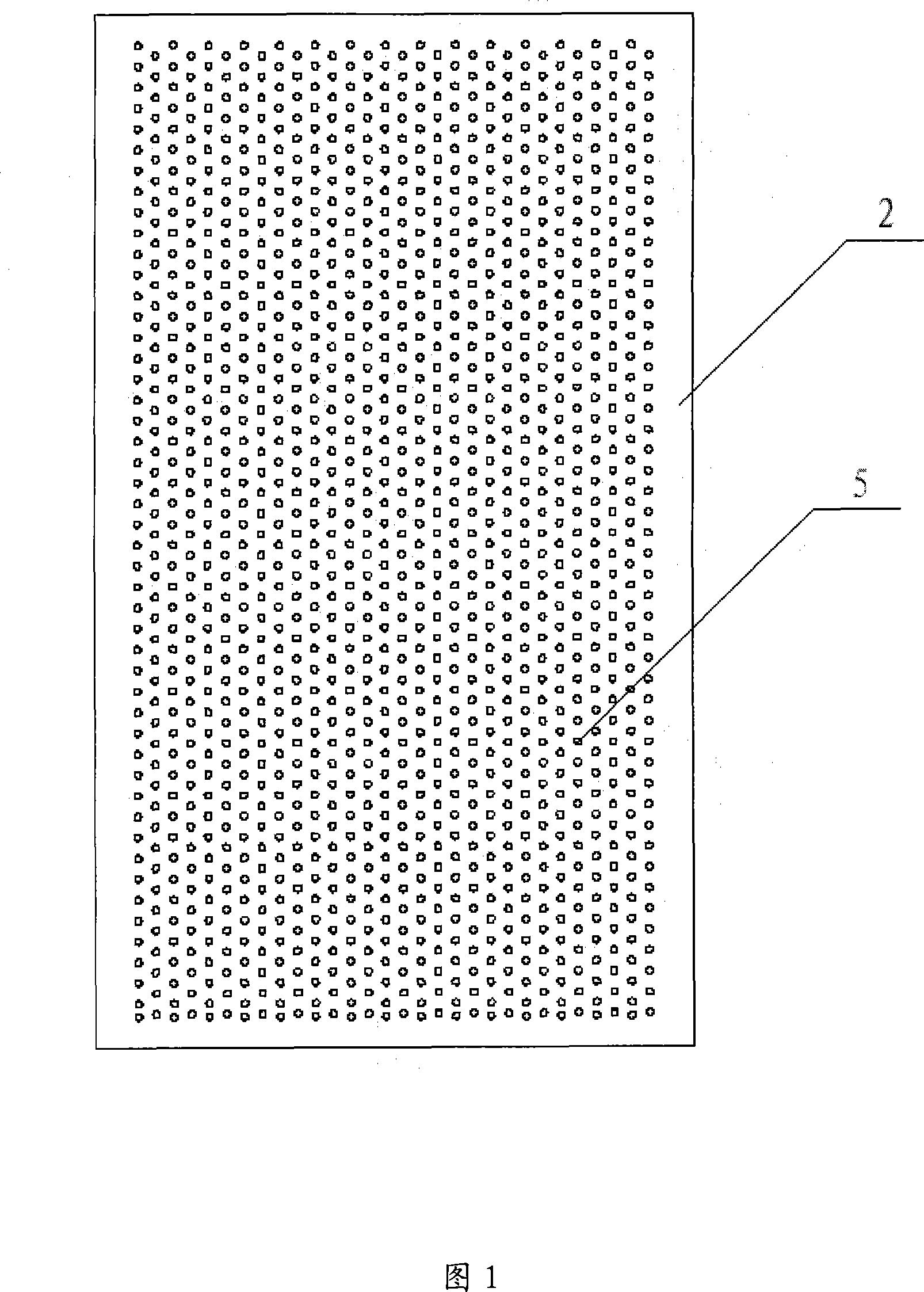

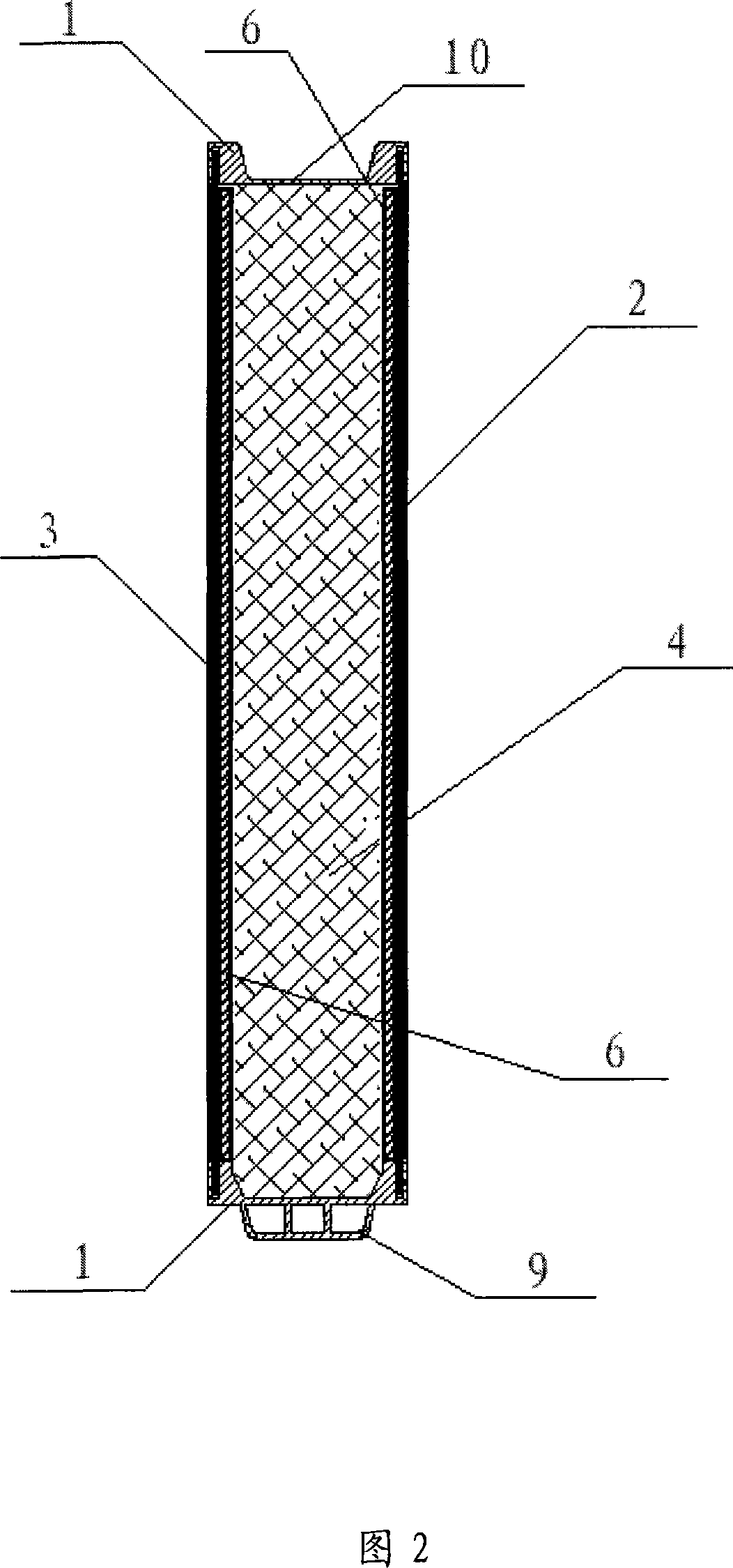

[0025] Embodiment 1: A kind of rigid polyvinyl chloride sound insulation barrier, the rigid polyvinyl chloride sound insulation barrier is made of the following raw materials in parts by mass, including 80 parts by mass of polyvinyl chloride, parts by mass 8 parts by mass of impact modifier polyacrylate, 8 parts by mass of filler calcium carbonate, 6.5 parts by mass of composite stabilizer lead stearate, 1 part by mass of UV protection agent 2-hydroxy -4-n-octyloxybenzophenone, the lubricant paraffin wax of 1 part by mass and the coloring agent of 1 part by mass;

[0026] A manufacturing process for synthesizing the above-mentioned rigid polyvinyl chloride sound barrier:

[0027] 1) Add 80 parts by mass of polyvinyl chloride into the thermomixer at low speed, increase the speed, then add 8 parts by mass of impact modifier polyacrylate, 8 parts by mass of Filler calcium carbonate, 6.5 parts by mass of composite stabilizer lead stearate, 1 part by mass of UV protection agent 2-...

Embodiment 2

[0033] Embodiment 2: Most of them are the same as in Embodiment 1, the difference is that the rigid polyvinyl chloride sound insulation barrier is made of the following raw materials in parts by mass, including 70 parts by mass of polyvinyl chloride, mass 12 parts of impact modifier chlorinated polyethylene, 4 parts by mass of filler clay, 6 parts by mass of composite stabilizer zinc stearate, 0.5 parts by mass of UV protection agent carbon black , 0.5 parts by mass of lubricant low molecular weight polyethylene and 0.01 parts by mass of coloring agent.

Embodiment 3

[0034] Embodiment 3: Most of them are the same as in Embodiment 1, the difference is that the rigid polyvinyl chloride sound insulation barrier is made of the following raw materials in parts by mass, including 90 parts by mass of polyvinyl chloride, mass 2 parts of impact modifier ethylene and vinyl ester copolymer, 12 parts by mass of filler clay and a mixture of calcium carbonate, 7 parts by mass of composite stabilizer barium stearate (or stearate Lead acid, zinc stearate, barium stearate, calcium stearate, cadmium stearate, cadmium laurate, barium laurate, cadmium ricinoleate, lead ricinoleate, tribasic lead sulfate, di-salt One or more of the basic lead phosphite, for the sake of brevity, no further examples), 0.75 parts by mass of the UV protection agent zinc oxide (or 2-hydroxyl-4-n-octyloxybenzophenone , carbon black, zinc oxide, titanium dioxide, calcium oxide, one or more, for the sake of brevity, no additional examples), 2 parts by mass of lubricant triple pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com