Patents

Literature

41results about How to "No coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing citric acid ester type compound

InactiveCN101830803AHigh catalytic activityShorten the esterification timeOrganic compound preparationCarboxylic acid esters preparationChemical synthesisBenzene

The invention discloses a method for synthesizing a citric acid ester type compound, which belongs to the technical field of chemical synthesis. The method comprises the following steps of: using citric acid and fatty alcohol as main raw materials, and using benzene sulfonic acid or amino benzene sulfonic acid as a catalyst; and performing esterification and the purification processes of acetylation, neutralization, washing, drying, distillation and the like. The catalyst has rich sources, a low cost and high activity, can be separated from an esterification liquid easily after the neutralization, is coke-free during the distillation, has less corrosion to equipment, and is safe and environment-friendly; the water generated by the esterification is separated out by adopting a binary heterogeneous separation technique, and no water separating agent is additionally added; and acetyl citric acid ester is produced by adopting an esterification-acetylation continuous synthesis method, the flow is greatly simplified, and a synthesis process is shortened. The citric acid ester prepared by the method has the advantages of high quality, high purity, low degree of color and wide applicationrange.

Owner:NORTHWEST NORMAL UNIVERSITY

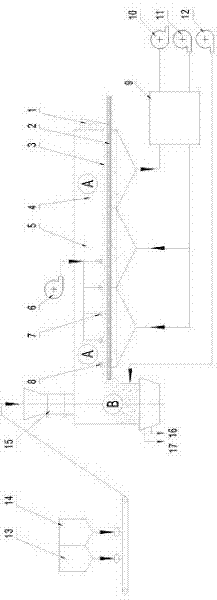

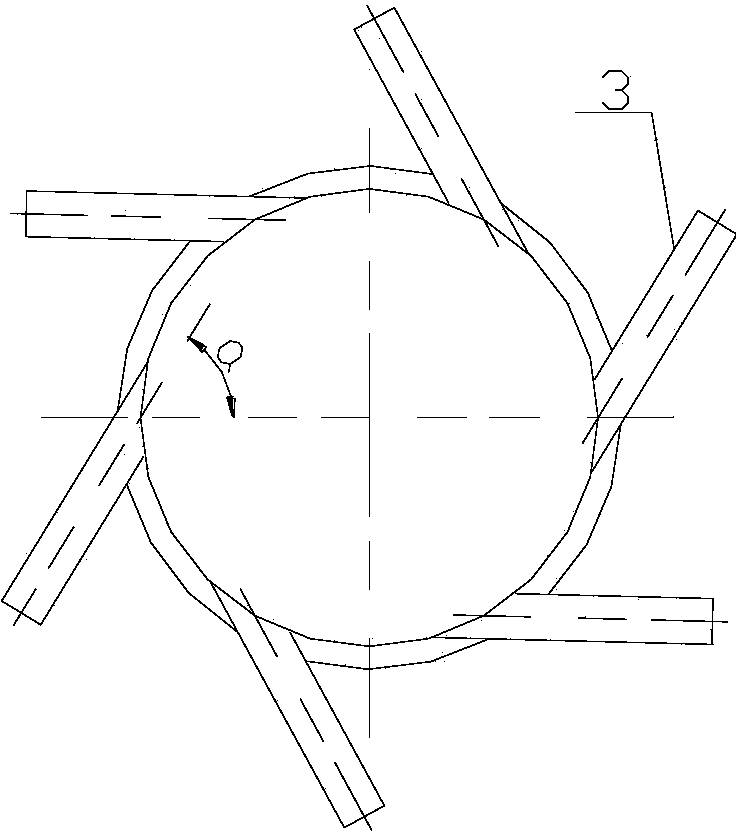

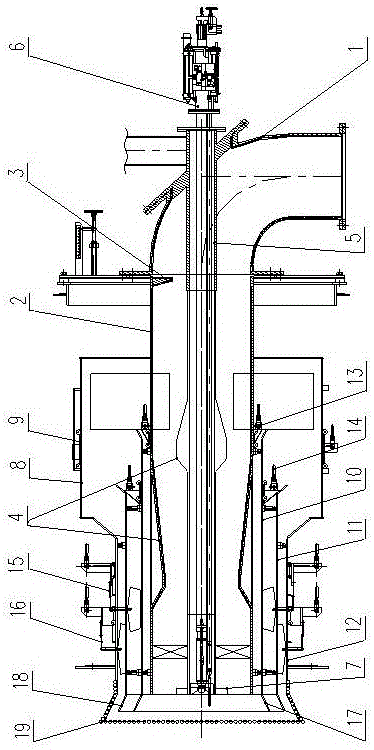

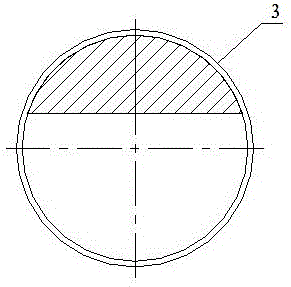

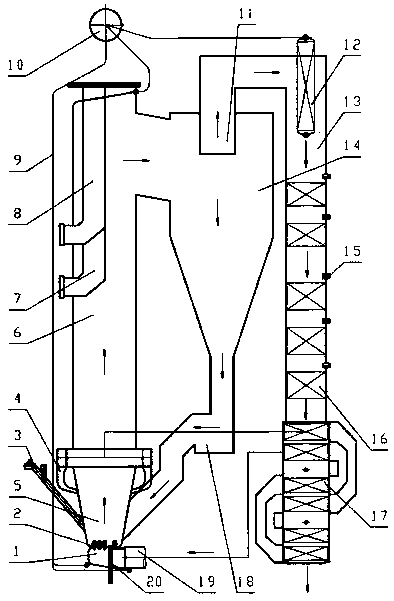

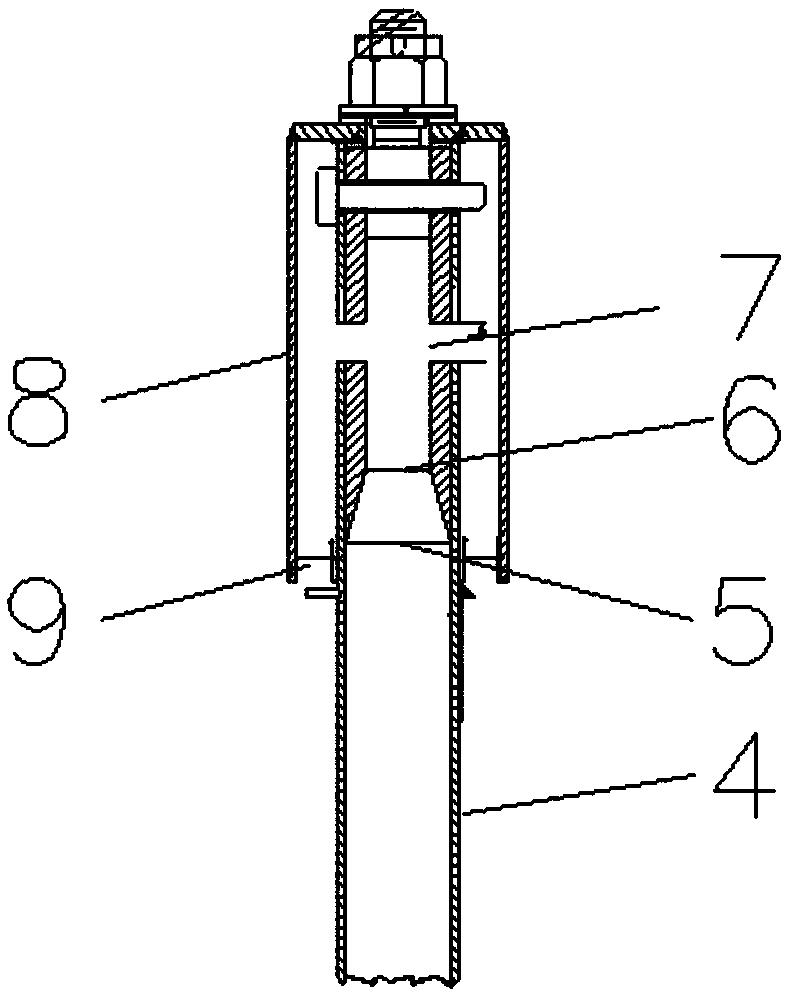

Continued ironmaking device based on melting reduction

The invention relates to a continued ironmaking device based on melting reduction of iron oxide containing carbon iron oxide balling (blocks). In the invention, the device is a continued ironmaking device based on melting reduction and can carry out continual tapping by pre-reducing furnace burden (3) through continually adding the furnace burden (3), extracting air, preheating, blasting and carrying out downstream roasting, and directly conveying the pre-reduced furnace burden (3) into a smelting-separating furnace (B) for continuous smelting-separation; a preheat area (4), a roasting area (5) and the smelting-separation areas behind the preheat area and the roasting area form a connected hearth; a combustion-supporting burner (8) and a secondary tuyere (7) are arranged also; preferably, the high-temperature coat gas generated in the smelting-separation area is subjected to secondary combustion in a pre-reduced furnace (A) for preheating and roasting the furnace burden (3); then the furnace burden (3) is discharged into the smelting-separation area for the further reduction, carburization and melting to separate the slag and iron; in the preheated area (4), the fuse passes through a bed of material to directly heat the furnace burden (3), and then the fuse enters a heat exchanging device (9) and a fuse process system; and a fan blasts the cool air below the bed into a hearth bottom (2) through the heat exchange device (9). The device has the advantages of short flow, reduced energy consumption, low carbon emission, low production cost, simple equipment, less occupied space, less investment and short building period.

Owner:李振洪

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

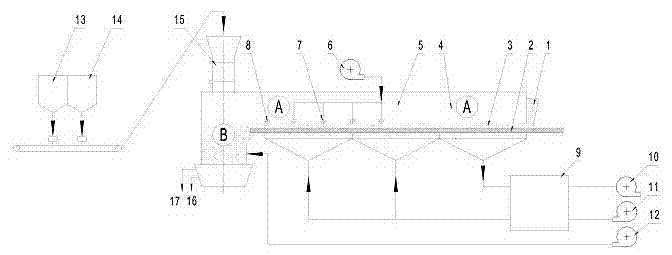

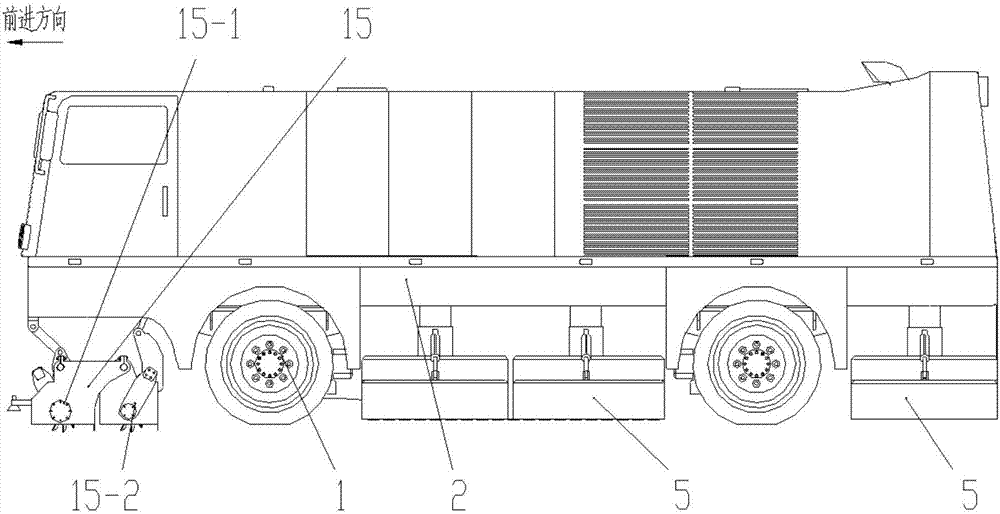

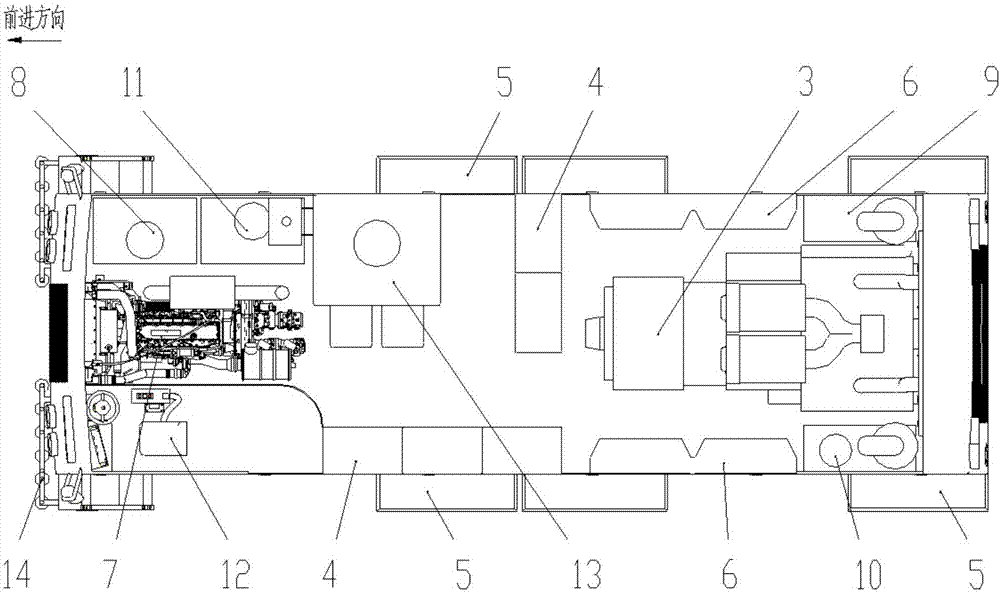

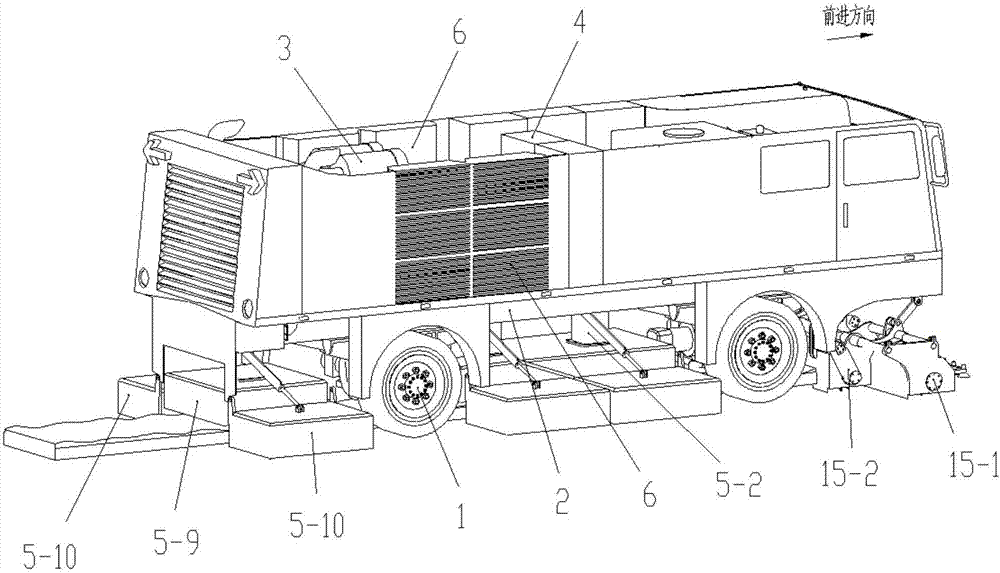

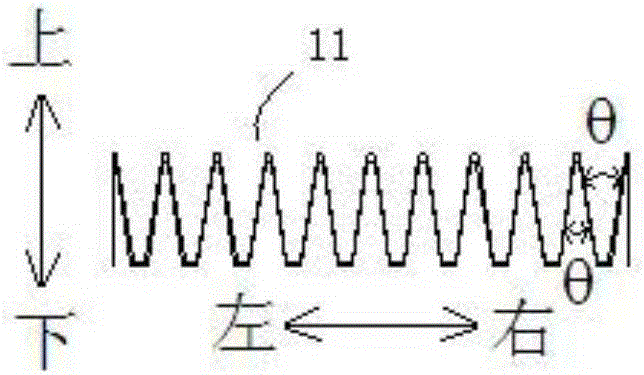

Microwave heating raking machine and microwave heating wall

The invention discloses a microwave heating wall for a microwave heating raking machine. The microwave heating wall consists of a main microwave heating wall and auxiliary microwave heating walls hinged to two sides of the main microwave heating wall, the main microwave heating wall and the auxiliary microwave heating walls have identical structure, several rows of microwave heating components are evenly arranged inside a microwave heating frame, each microwave heating component comprises a microwave generation magnetron, a waveguide antenna is connected below a microwave radiation port of the microwave generation magnetron, and a wave transparent protection board is horizontally arranged below the waveguide antenna. The microwave generation magnetrons in the main microwave heating wall generate microwave energy with frequency of 2.45GHz, and the microwave generation magnetrons in the auxiliary microwave heating walls generate microwave energy with frequency of 5.8GHz. According to the invention, a 2.45GHz and 5.8GHz frequency combined microwave heating technology is employed to realize reheating and temperature raising of asphalt pile gathered after harrowing and thermal caking heating of asphalt pavement after harrowing, the asphalt material is free of aging and coking, and is efficient and environment-friendly.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

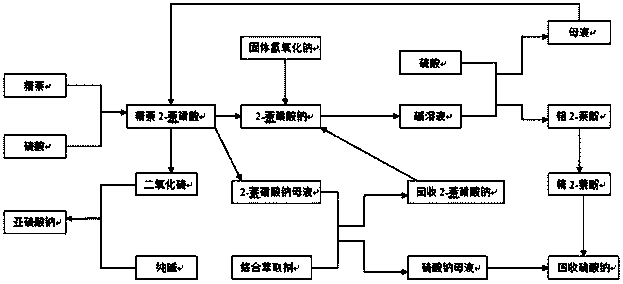

Environment-friendly preparation technology for producing 2-naphthol by liquid phase alkali fusion method

InactiveCN104193593AAchieving zero emissionsEvenly heatedOrganic compound preparationSulfonic acids salts preparationChemistry2-Naphthol

An environment-friendly preparation technology for producing 2-naphthol by a liquid phase alkali fusion method comprises the steps of sulphonating refined naphthalene into a sulfonation solution, neutralizing with a diluent after coarse 2-naphthol is separated to form 2-sodium naphthalene sulfonate or 2-potassium naphthalene sulfonate, then carrying out liquid phase alkali fusion with 20-50% of sodium hydroxide or potassium hydroxide (anhydrous alkali fusion after drying 2-sodium naphthalene sulfonate in the traditional technology), acidizing a mother solution after 2-sodium naphthalene sulfonate is filtered, extracting with an N235 complexation extraction agent, carrying out oxide purification and other procedures, and performing MVR (mechanical vapor recompression) concentrate and crystallization to produce sodium sulfate or potassium sulfate, wherein the liquid phase alkali fusion avoids coking of materials and increases yield.

Owner:青岛奥盖克化工股份有限公司

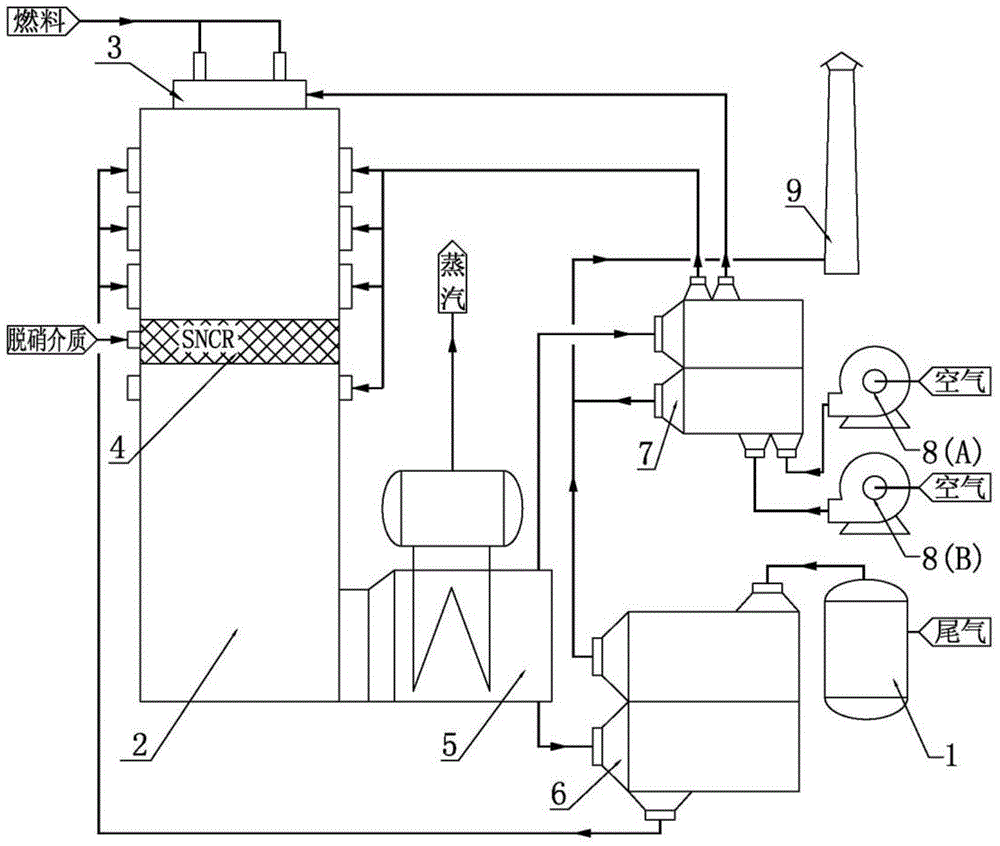

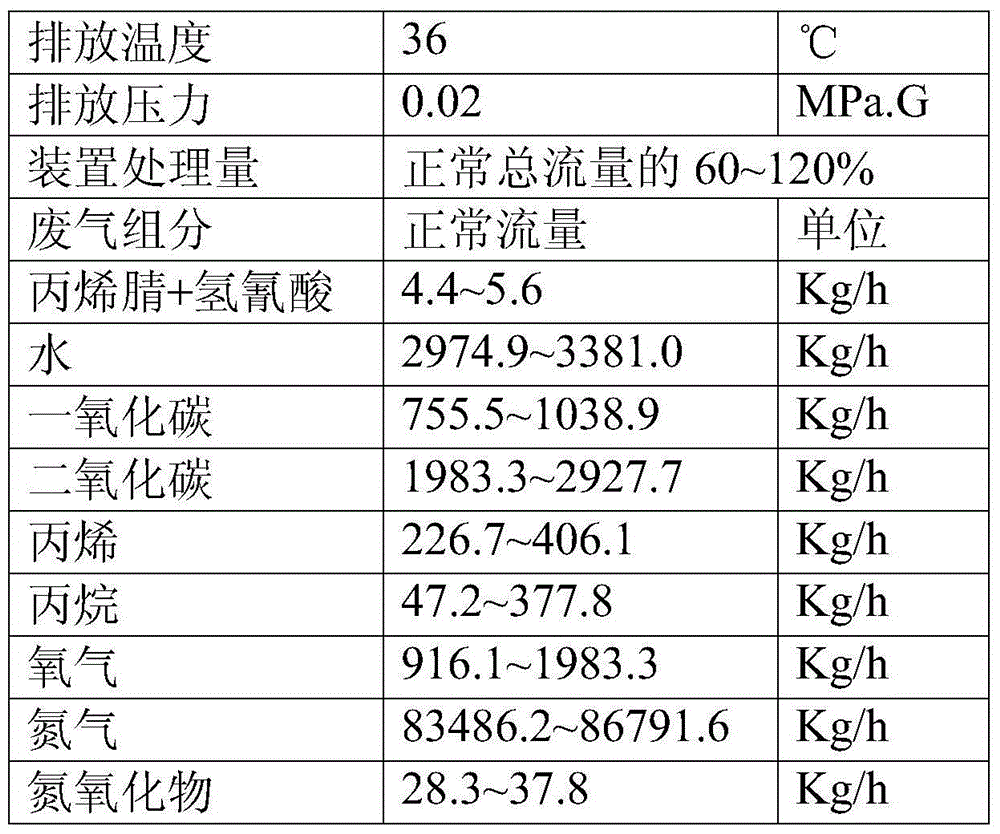

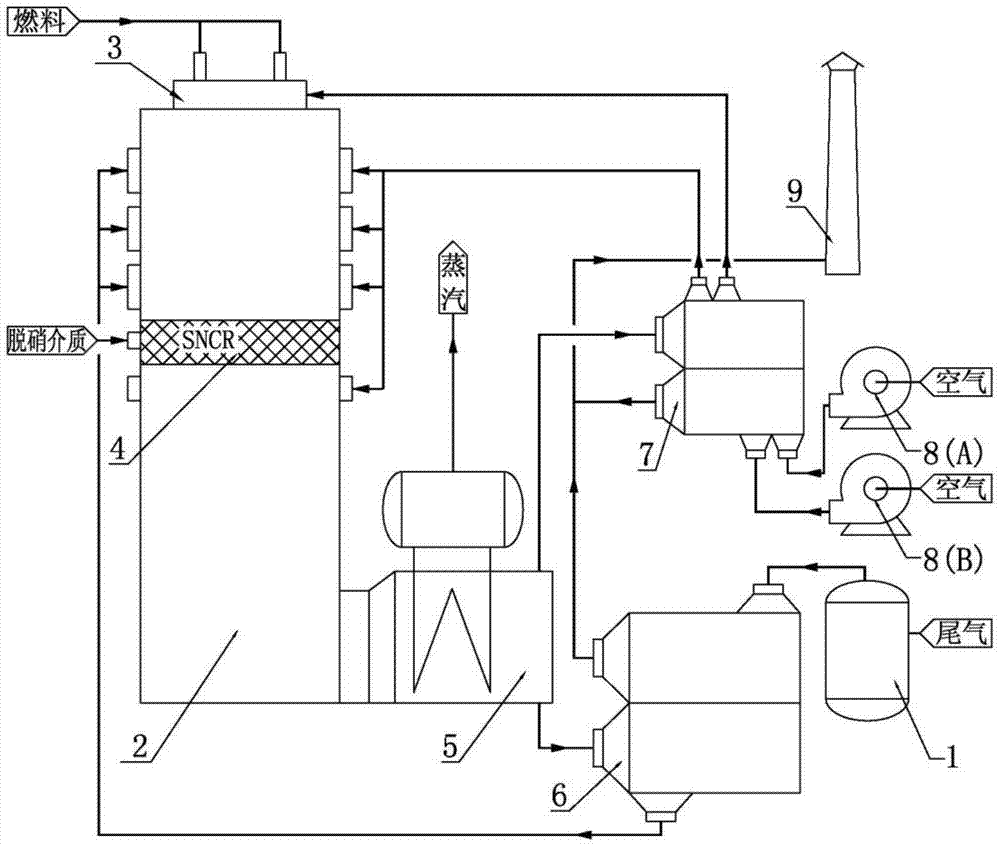

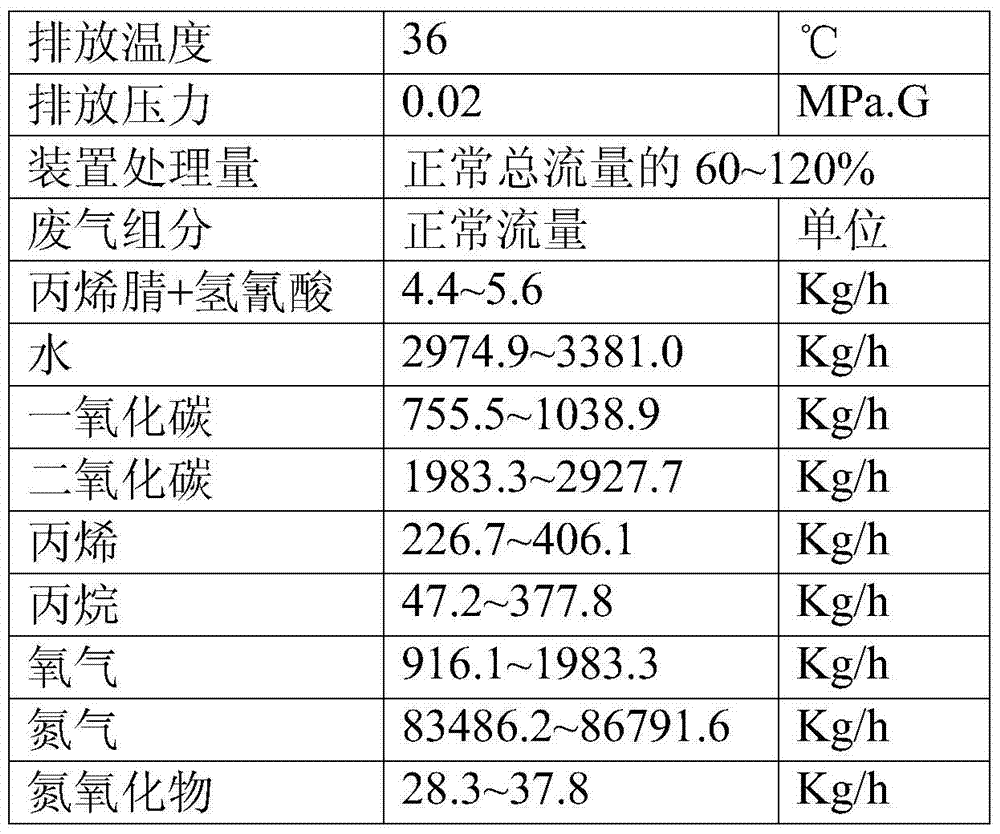

Process and system for treating vinyl cyanide tail gas by high temperature burning method

ActiveCN104807021ARealize high temperature oxidation decompositionReduce consumptionIncinerator apparatusHazardous substanceAdditive ingredient

The invention belongs to the environmental protection technology field of organic waste gas treatment and particularly relates to a process for pretreating and burning vinyl cyanide tail gas and a system for recycling waste heat of vinyl cyanide tail gas. The system comprises a gas-liquid separation tank, an incinerator, a combustion-supporting device, an SNCR (selective non-catalytic reduction) denitrification device, a waste heat boiler, a vinyl cyanide tail gas-exhaust gas continuous heat accumulation heat exchanger, a combustion-supporting air-exhaust gas continuous heat accumulation heat exchanger, an air blower and a chimney. According to a system for treating vinyl cyanide tail gas by a high temperature burning method, hazardous substances such as vinyl cyanide, hydrocyanic acid, carbon monoxide and non-methane hydrocarbon in the vinyl cyanide tail gas can realize high temperature oxidation decomposition, and the removal rate of the hazardous substances reaches beyond 99.99%. In comparison with the traditional high temperature burning method, 60-70% of fuel consumption can be directly saved; the treating method is high-efficiency and energy-saving, and the preheating temperature is lower 20-30 degrees centigrade than the decomposition temperature of organic ingredients in the tail gas, and thus the method is safe and steady and no coking is occurred.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

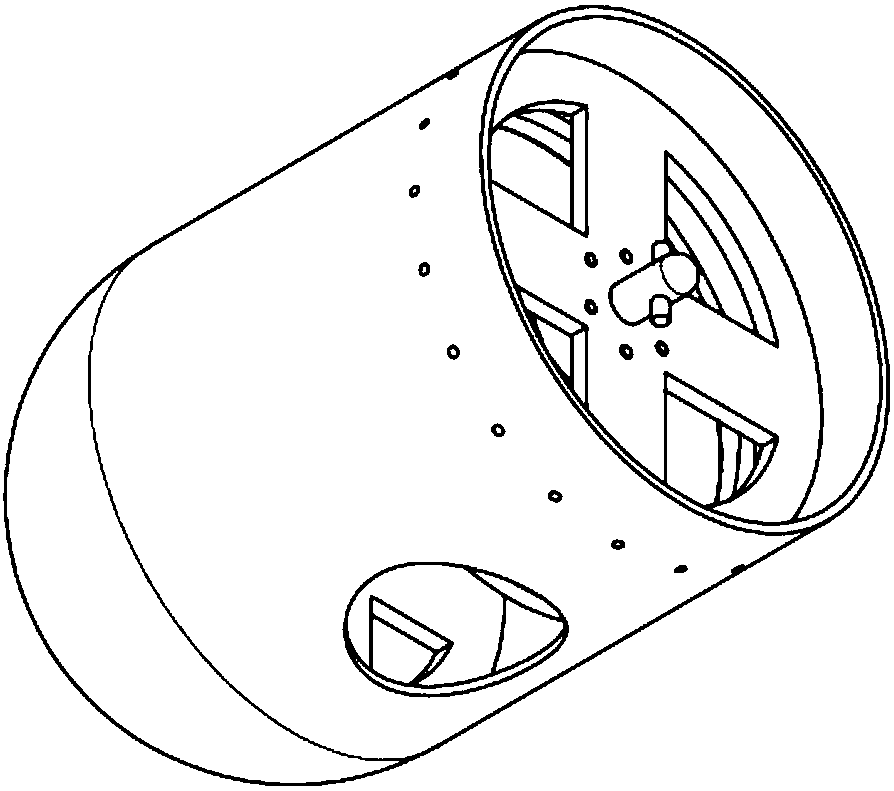

Plasma pyrolytic coal-derived acetylene reactor

ActiveCN104355961AImprove temperature uniformityAvoid being burnedHydrocarbonsHydrocarbon preparationMetallurgyPlasma generator

The invention discloses a plasma pyrolytic coal-derived acetylene reactor. A plurality of plasma generators and a plurality of coal powder input nozzles are mounted on the reactor, and high-temperature ionized gas produced by the plasma generators and coal powder sprayed out by the coal powder input nozzles are mixed to form coal powder and gas mixed reactant in the reactor; a plurality of solid powder spray nozzles are mounted below the coal powder input nozzles on the wall of the reactor, a flowing solid powder isolating layer is formed by solid powder which is sprayed out by a plurality of solid powder spray nozzles on the inner wall of the reactor, the flowing solid powder isolating layer is encircled to form a pyrolytic reaction passage, and the axial flow direction of the flowing solid powder isolating layer is consistent with the flow direction of the coal powder and gas mixed reactant. Through use of the plasma pyrolytic coal-derived acetylene reactor disclosed by the invention, the heat energy depletion is reduced, the reaction efficiency and the acetylene recovery are improved, the coking problem of the wall of the reactor is completely solved, and the wall of the reactor can be protected from being over burned.

Owner:合肥碳艺科技有限公司

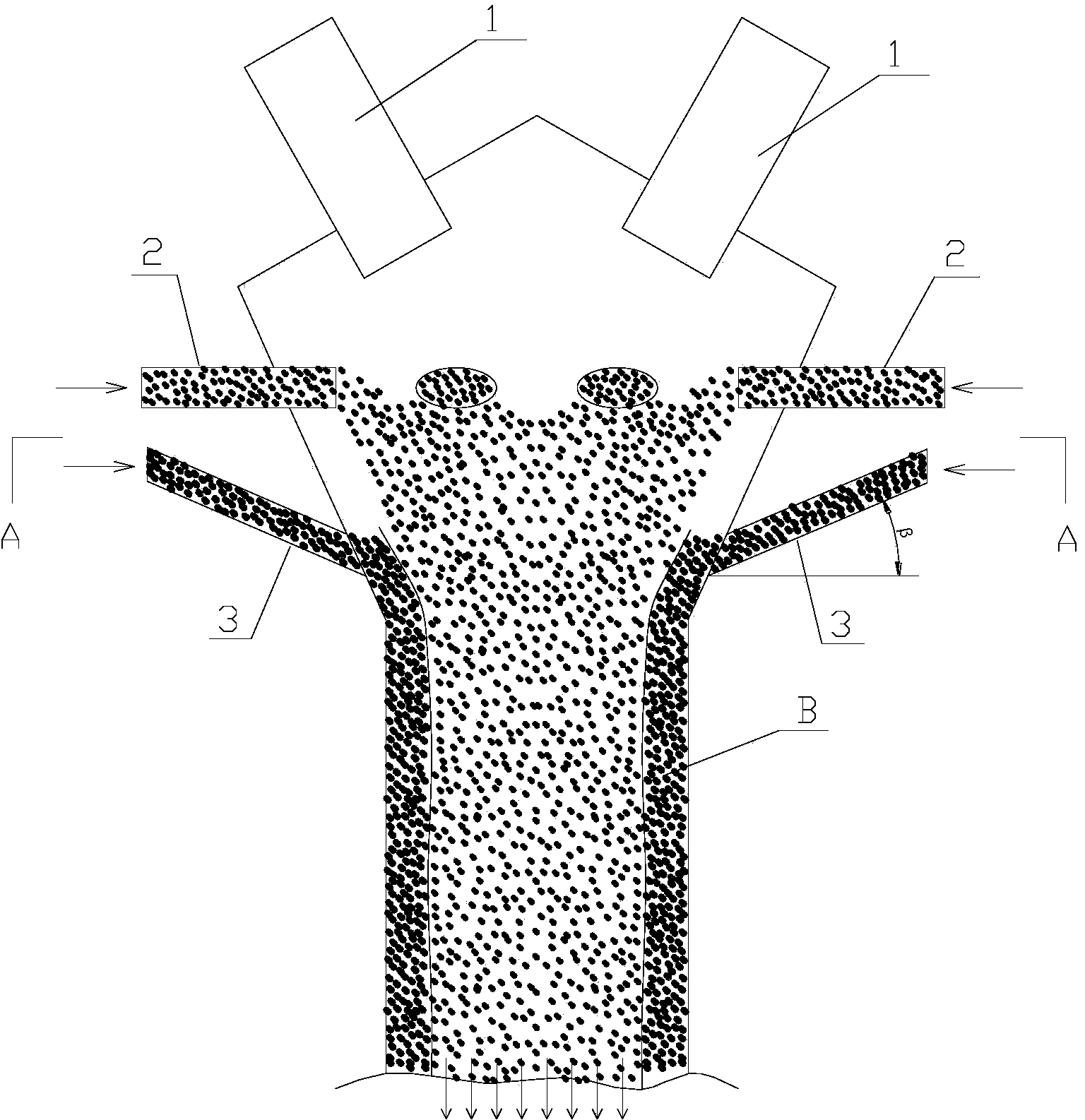

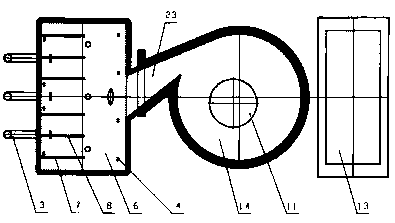

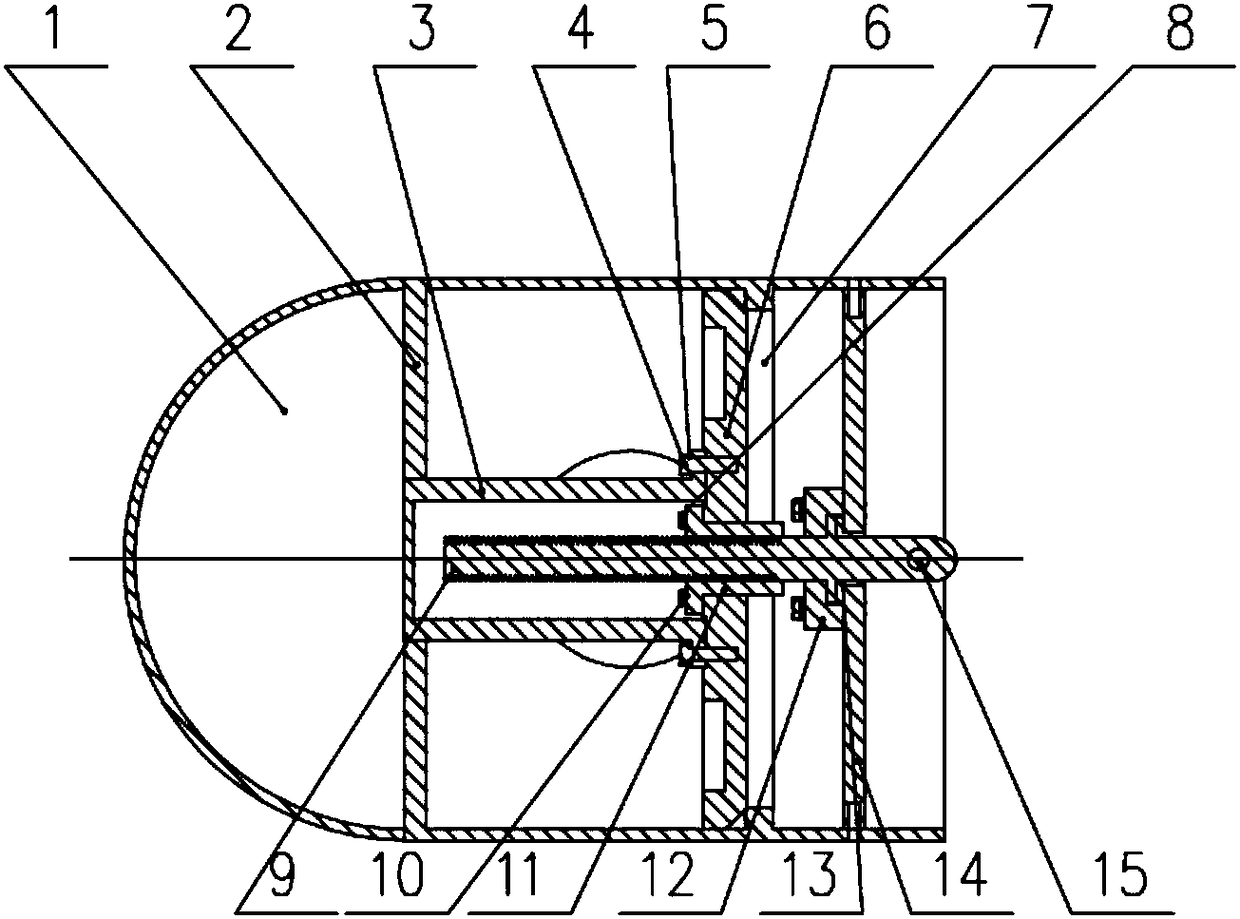

Multi-level separation annular backflow type axial cyclone burner

InactiveCN106196041AEmission reductionSmall running resistancePulverulent fuel combustion burnersCycloneDistributor

The invention discloses a multi-level separation annular backflow type axial cyclone burner. According to the existing cyclone burner technology, emission of NOx needs to be further reduced, and the burn-off rate needs to be further increased. A primary air pipe bend (1) and a primary air pipe horizontal section (2) are connected. A center air pipe assembly (5) is arranged in the center of the primary air pipe horizontal section, a pulverized coal uniform distributor (3) is arranged at an inlet, a Venturi pulverized coal concentrator (4) is arranged close to an outlet, and the outlet is connected with a burning stabilizer (7). A secondary air pipe (10) and a secondary air brake (13) are arranged at the outer portion of the primary air pipe horizontal section. A tertiary air pipe (11) and a tertiary air brake (14) are arranged at the outer portion of the secondary air pipe. An outlet of the tertiary air pipe is connected with a tertiary air flaring (17). The tertiary air pipe is provided with a tertiary air cyclone adjusting mechanism (15). A quartic air pipe (12) is arranged at the outer portion of the tertiary air pipe and provided with a quartic air cyclone adjusting mechanism (16), and an outlet of the quartic air pipe is connected with a water wall tube panel (18). The multi-level separation annular backflow type axial cyclone burner is used in the field of multi-level separation annular backflow type axial cyclone burners.

Owner:HARBIN BOILER

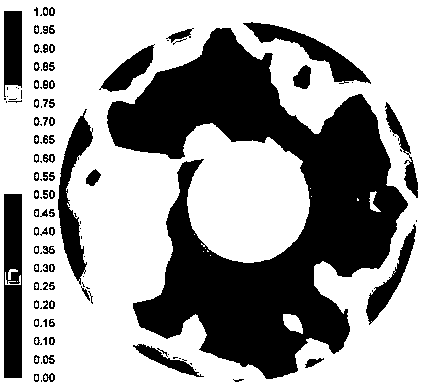

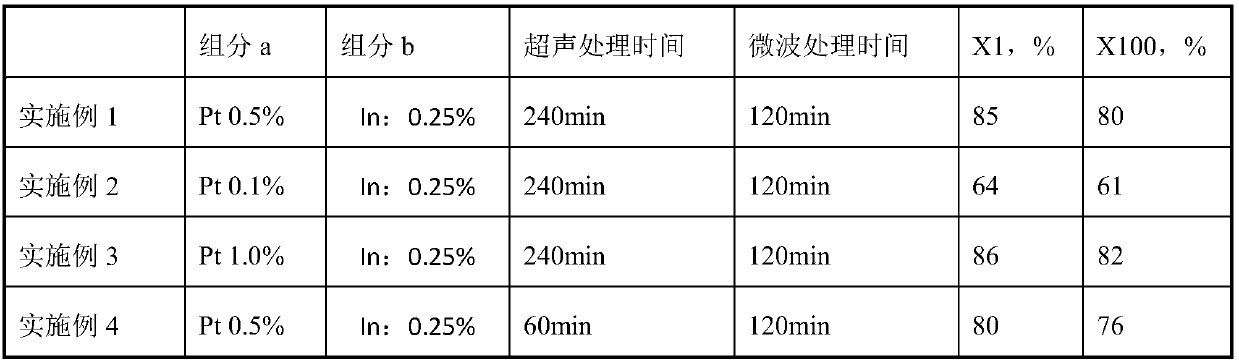

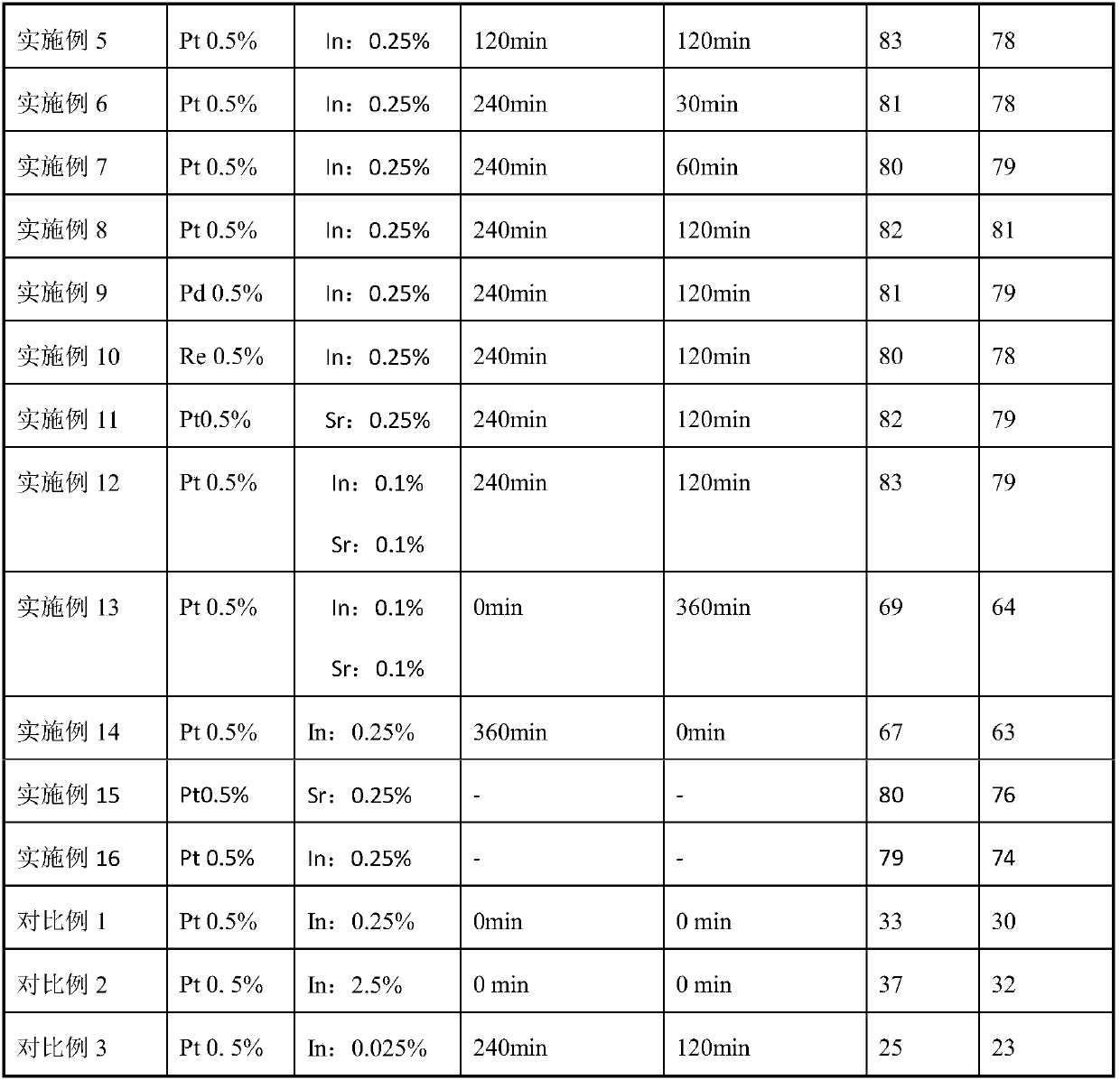

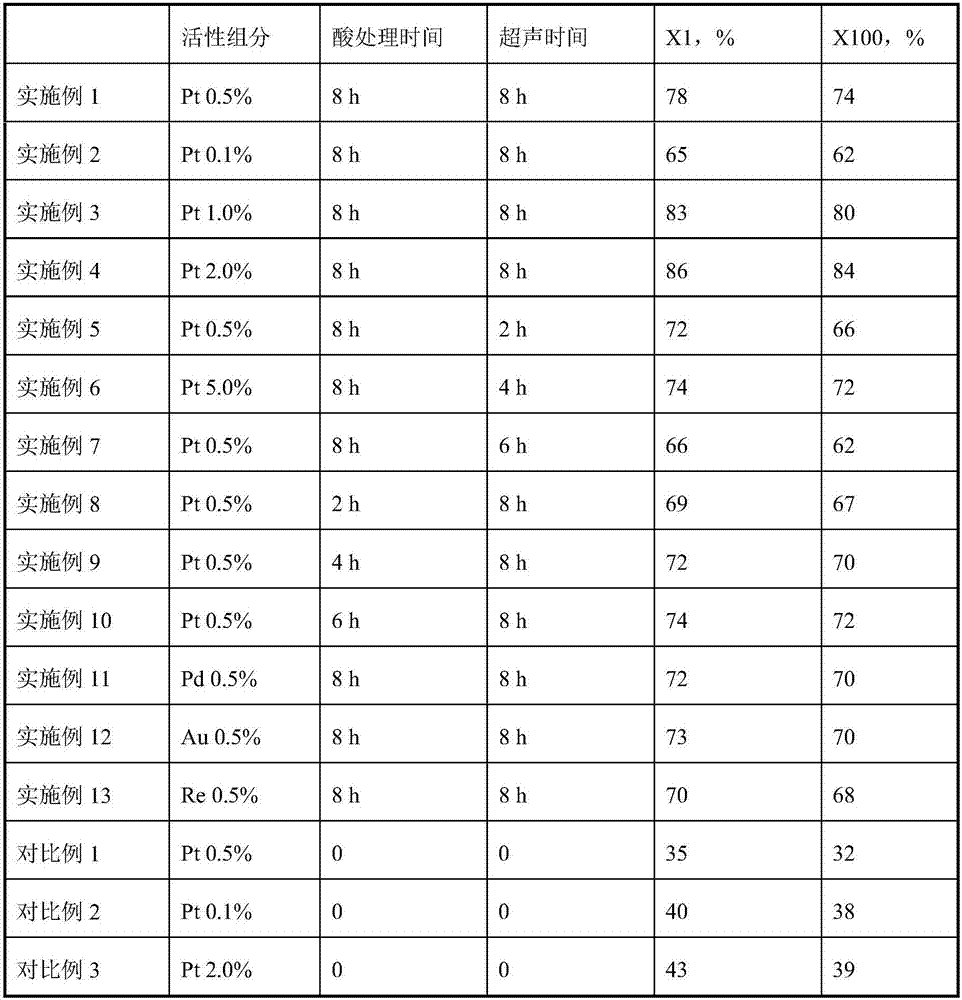

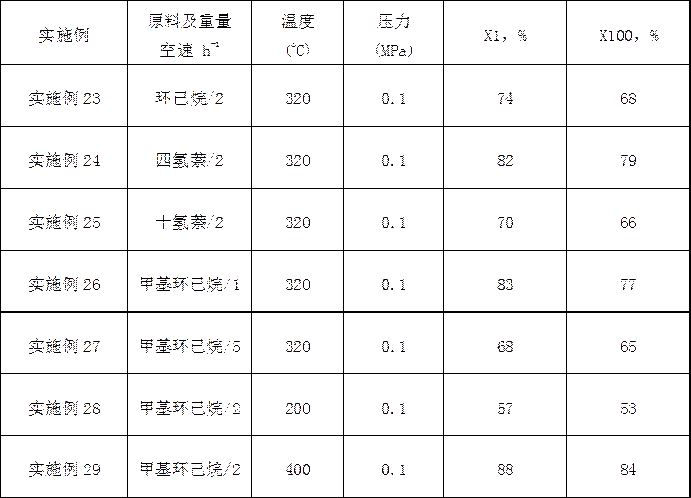

High-dispersion dehydrogenation catalyst, and preparation method and use method of same

The invention discloses a high-dispersion dehydrogenation catalyst, and a preparation method and a use method of same. The catalyst is composed of: (a) 0.1 to 5 parts of an active component, (b) 0.1 to 2 parts of at least one metal element, selected from subgroup elements, or a metal oxide thereof, and (c) 95 to 99.9 parts of graphene. The preparation method includes: dispersing graphene in an organic solvent, introducing metal salt of the active component, stirring the mixture, adding a certain amount of a reducing agent, performing microwave treatment to obtain an insoluble product, and filtering, washing and drying the insoluble product to obtain the high-dispersion dehydrogenation catalyst, which has high metal dispersibility, is small in size, and is free of acidity of the carrier. The catalyst, when being used for low-carbon alkane dehydrogenation or dehydrogenation reactions of organic liquid hydrogen storage materials, is high in activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

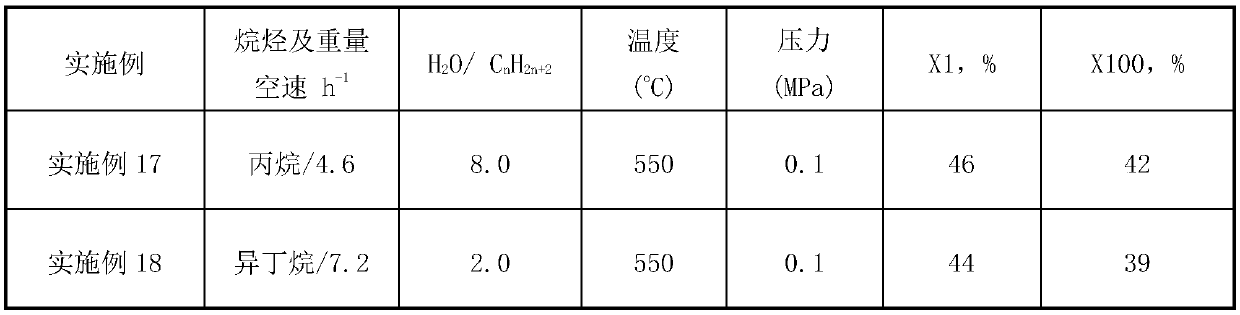

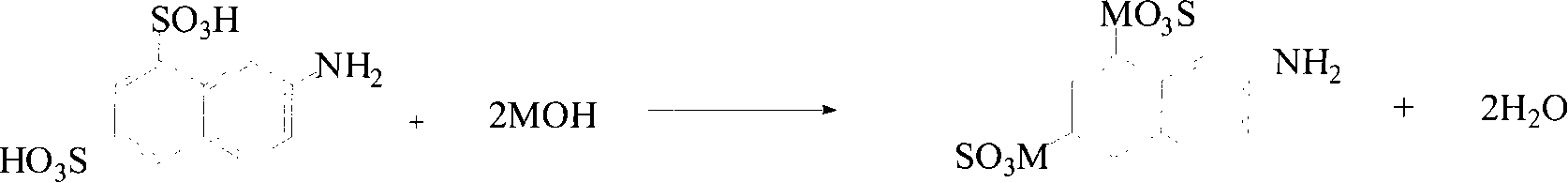

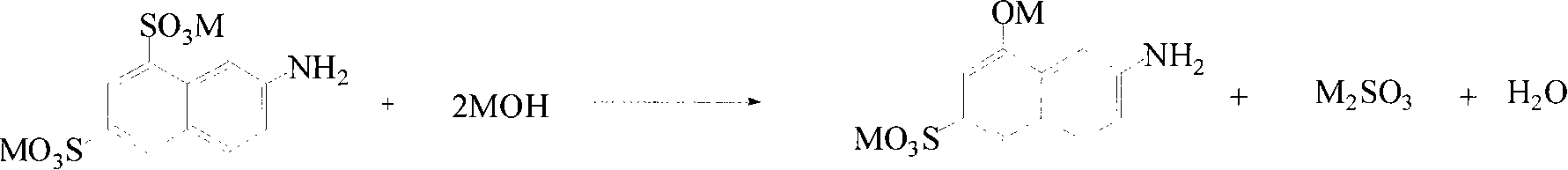

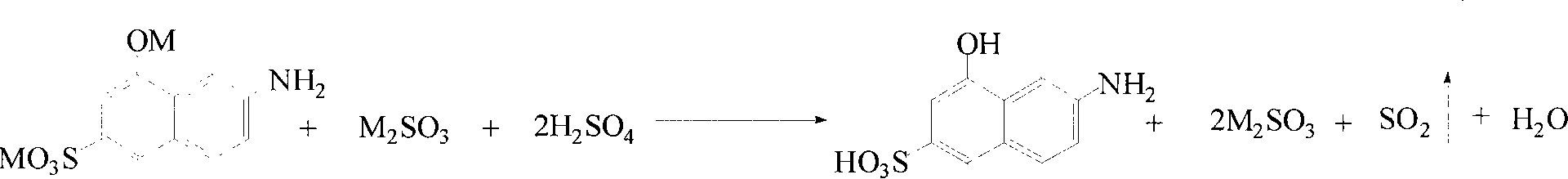

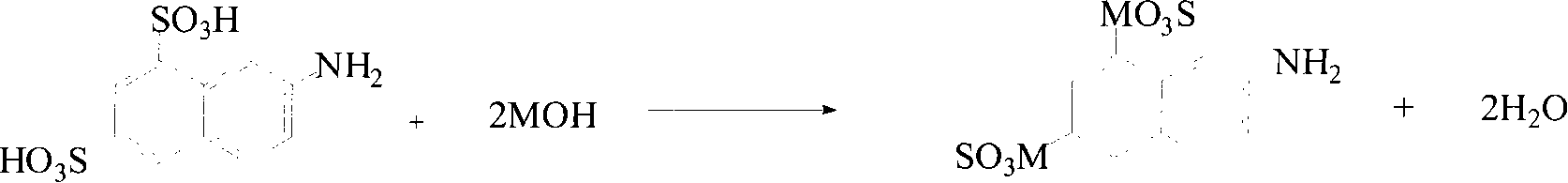

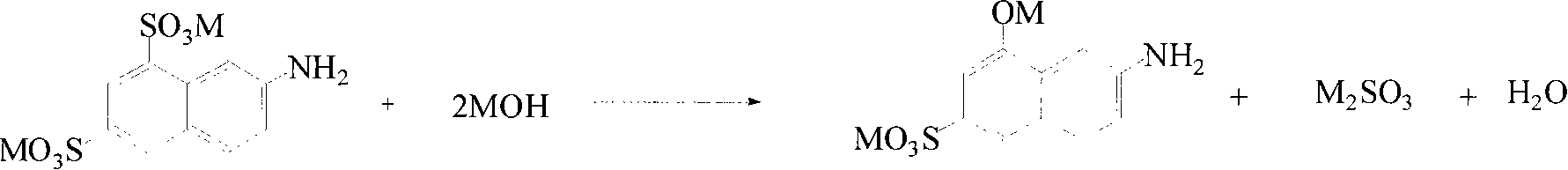

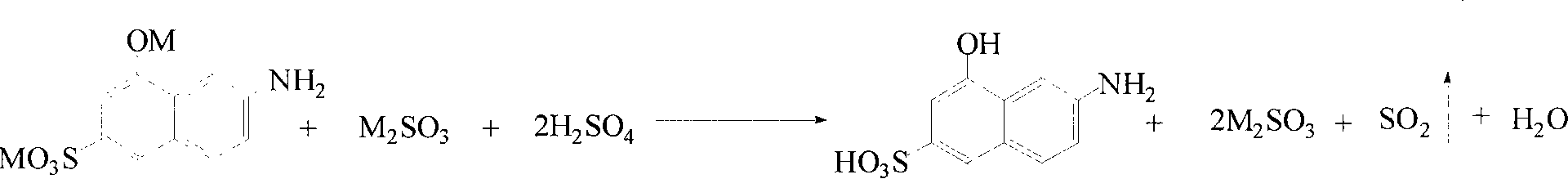

Method for preparing 2-amido-8-naphthol-6-sulfonic acid

InactiveCN101182301AImprove liquidityReduce power consumptionSulfonic acid preparationState of artAmmonia

The invention relates to a method for preparing 2-amino-8-naphthol-6-sulfonic acid. The method uses 2-naphthylamine-6,8-disulfonic acid or its salt as raw material and alkali solution under stirring conditions reaction, and then transferred to a pressure reaction kettle for pressure alkali fusion in the state of no ammonia, and finally after cooling down, acidifying the alkali melt with acid to obtain the target product 2-amino-8-naphthol-6-sulfonic acid. Compared with the prior art, the process reaction system of the present invention has better fluidity, less power consumption, no coking, high product purity, less environmental pollution, and the product can be directly used in the synthesis of high-grade dyes and organic pigments without refining.

Owner:浙江海晨化工有限公司

Multistage separation center backflow axial cyclone burner

ActiveCN106051759AImprove coal adaptabilityEmission reductionPulverulent fuel combustion burnersCycloneCombustion

The invention discloses a multistage separation center backflow axial cyclone burner. A traditional cyclone burner technology needs to further reduce NOx emission. A primary wind pipe elbow (1) is connected with a primary wind pipe horizontal section (2); a center wind pipe module (5) and a connected combustion stabilizing ring (7) are arranged in the center of the primary wind pipe horizontal section; a pulverized coal uniform distributor (3) is arranged in an inlet; a venturi pulverized coal concentrator (4) is arranged near an outlet; a secondary wind pipe (10), a secondary wind gate (13) and a secondary wind pipe expanding port (17) are arranged at the external of the primary wind pipe horizontal section; a ternary wind pipe (11), a ternary wind gate (14) and a ternary wind pipe expanding port (18) are arranged at the external of the secondary wind pipe; the ternary wind pipe is provided with a ternary wind cyclone adjusting mechanism (15); a quartic wind pipe (12) is arranged at the external of a ternary wind pipe; the quartic wind pipe is provided with a quartic wind cyclone adjusting mechanism (16); and an outlet of a quartic wind pipe is connected with a water cooling wall pipe screen (19). The invention is applied to the multistage separation center backflow axial cyclone burner.

Owner:HARBIN BOILER

Modified carbon nanometer material

PendingCN107970919AHigh dispersion of PtImprove stabilityHydrogenCatalystsAlkaneMaterials preparation

The invention discloses a modified carbon nanometer material, a preparation method and uses thereof. The modified carbon nanometer material comprises (a) 0.1-5 parts of an active component and (b) 95-99.9 parts of a carbon nanometer material. The preparation method comprises: (1) carrying out strong acid treatment on a carbon nanometer material; and (2) introducing an active component through impregnation or precipitation in an ultrasonic manner. According to the present invention, the prepared modified carbon nanometer material can solve the problems of low active component loading and poor dispersion of the current material preparation method; and with the application of the modified carbon nanometer material in the low-carbon alkane dehydrogenation or organic liquid hydrogen storage material dehydrogenation reaction, the catalyst has the following advantages that the Pt dispersion degree is high, the carrier is acid-free, the reaction process is substantially non-coking, the activity is high, and the stability is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

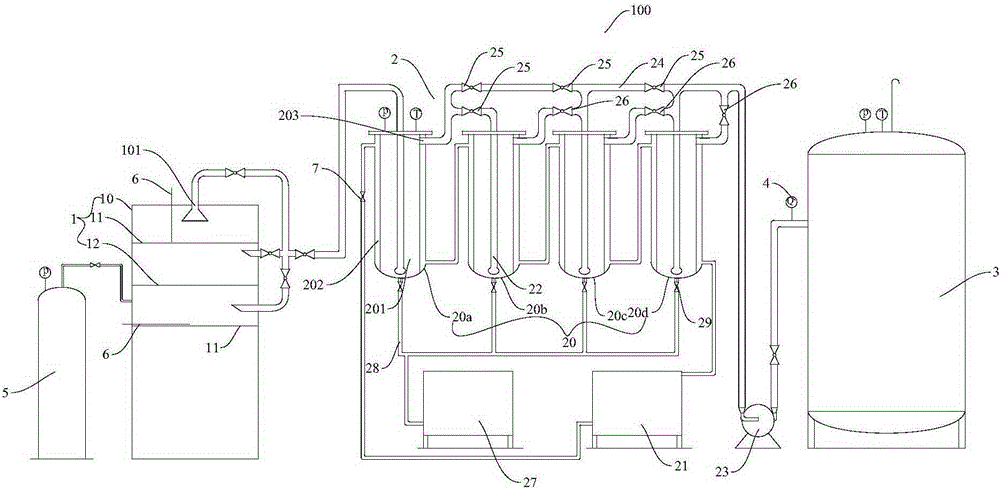

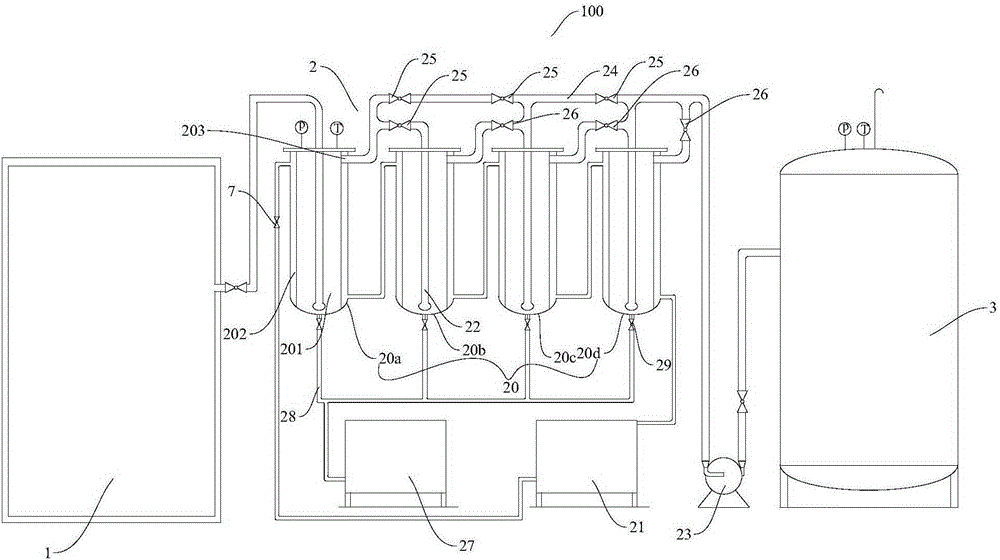

Pyrolysis device

ActiveCN104164249BHigh thermal efficiencyHeating up fastIndirect heating destructive distillationLiquid hydrocarbon mixture productionSingle processEngineering

The invention discloses a pyrolyzer which comprises a pyrolyzing furnace, a cooler assembly and a gas storage tank, wherein the pyrolyzing furnace comprises a furnace body, two cloth boards and a heating radiation tube; the furnace body is provided with an oil-gas outlet; the two cloth boards are separately arranged in the furnace body in the up-and-down direction; each cloth board is provided with a plurality of through holes which are penetrative in the thickness direction; and the heating radiation tube is arranged in the furnace body and positioned between the two cloth boards. The cooler assembly is connected with the oil-gas outlet. The gas storage tank is connected with the cooler assembly and used for receiving pyrolysis gas. The pyrolyzer accelerates the material heating, enables the material to be heated uniformly, does not have coking, effectively increases the single-process treatment capacity, can fully utilize the radiation heat of the heating radiation tube, and has higher heat efficiency; and thus, the pyrolyzer is convenient for releasing the oil-gas mixture, and the generated oil-gas mixture contains fewer solid products, thereby avoiding the blockage of the oil-gas outlet.

Owner:SHENWU TECH GRP CO LTD

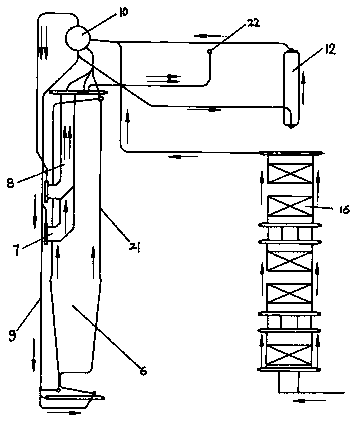

Circulating fluidized bed boiler and flow state reconstruction method suitable for high-viscosity flue gas

PendingCN111336503APrevent slaggingAvoid stickingFluidized bed combustionApparatus for fluidised bed combustionFlue gasFluidized bed

The invention discloses a circulating fluidized bed boiler and a flow state reconstruction method suitable for high-viscosity flue gas, and solves the problem that flow state reconstruction is neededwhen a circulating fluidized bed boiler uses coal ultra-high in alkali metal content as fuel. A superheated screen (8) is arranged in a hearth (6), a convection evaporation tube bundle (12) is arranged on the upper portion of a tail shaft flue (13), the convection evaporation tube bundle adopts a longitudinal sequence pipe bundle distribution form and communicates with a boiler barrel (10) througha water guide pipe, the boiler barrel communicates with the superheated screen through another water guide pipe, a high-temperature cyclone separator (14) is arranged on one side of the hearth, and the diameter of an upper barrel body of the high-temperature cyclone separator is 5-7 meters, and a center barrel (11) on the upper portion of the high-temperature cyclone separator is offset from thehigh-temperature cyclone separator; and the length-to-width ratio of the hearth is 1:2, and the shrinkage ratio of a fluidized bed at the lower part of the hearth is 0.45-0.5. Accumulated ash is effectively reduced, and the operation efficiency of the boiler is improved.

Owner:TAIYUAN BOILER GROUP

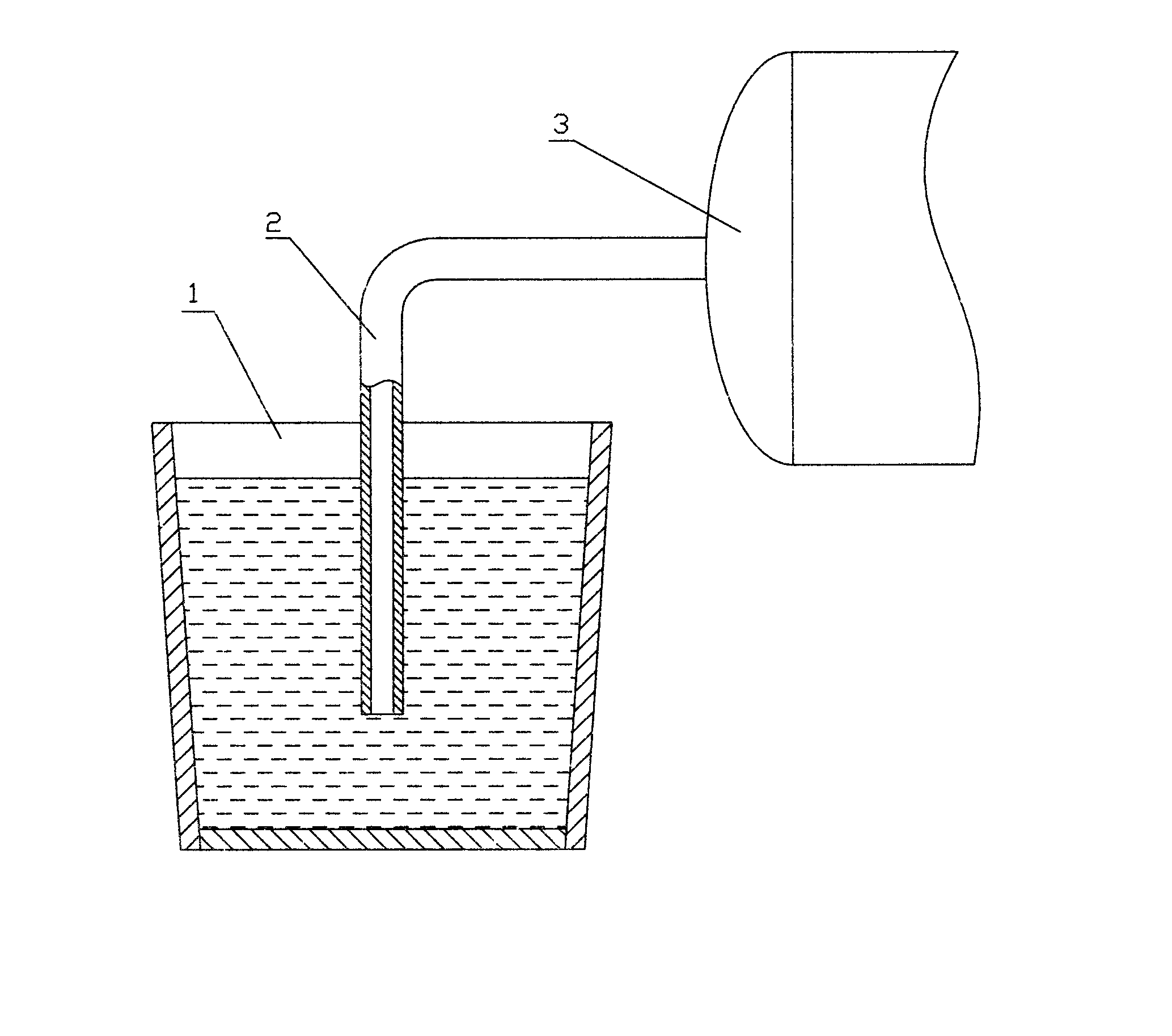

Method and processing device for breeding young tegillarca granosa

InactiveCN103229740AEvenly heatedNo hardeningClimate change adaptationPisciculture and aquariaAdditive ingredientAntibiotic Y

The invention relates to a method and a processing device for breeding young tegillarca granosa, wherein a breeding chamber and regulation and control conditions of physicochemical environment in an algae workshop are involved; the breeding steps are as follows: (1) inducing spawning, (2) washing eggs and incubating, (3) selecting excellent ones, (4) breeding larvae, (5) preprocessing an attachment substrate, (6) collecting and distributing in a pool, and (7) breeding juvenile mollusks. The method is characterized in that the step (5) of preprocessing the attachment substrate comprises screening and washing the collected beach bottom mud by using a 150-200 mesh screen, rinsing out organic matters after precipitation, and then directly putting the beach bottom mud in a container barrel for boiling by introducing boiler steam into the beach bottom mud, and then cooling before distributing in the pool. The device is characterized in that a steam pipe extending out of a boiler extends into the container barrel and the lower mouth of the steam pipe is located under the mud surface of the beach bottom mud. The method and the processing device have the advantages that the beach bottom mud is boiled by steam so that heating is even and no hardening and coking are caused, the nutritional ingredients of the attachment substrate are kept, and drugs such as antibiotics, chloromycetin, potassium permanganate and the like are not used for sterilization, and the survival rate of breeding is high. After the method and the processing device provided by the invention are applied, the survival rate is increased to the range from 60% to 80%; and the yield of the young tegillarca granosa per square meter per batch reaches up to 0.35 kg.

Owner:宁德市渔海水产科技有限公司

A process and system for treating acrylonitrile tail gas by high temperature incineration

ActiveCN104807021BRealize high temperature oxidation decompositionReduce consumptionIncinerator apparatusEnvironmental resistanceDecomposition

The invention belongs to the environmental protection technology field of organic waste gas treatment and particularly relates to a process for pretreating and burning vinyl cyanide tail gas and a system for recycling waste heat of vinyl cyanide tail gas. The system comprises a gas-liquid separation tank, an incinerator, a combustion-supporting device, an SNCR (selective non-catalytic reduction) denitrification device, a waste heat boiler, a vinyl cyanide tail gas-exhaust gas continuous heat accumulation heat exchanger, a combustion-supporting air-exhaust gas continuous heat accumulation heat exchanger, an air blower and a chimney. According to a system for treating vinyl cyanide tail gas by a high temperature burning method, hazardous substances such as vinyl cyanide, hydrocyanic acid, carbon monoxide and non-methane hydrocarbon in the vinyl cyanide tail gas can realize high temperature oxidation decomposition, and the removal rate of the hazardous substances reaches beyond 99.99%. In comparison with the traditional high temperature burning method, 60-70% of fuel consumption can be directly saved; the treating method is high-efficiency and energy-saving, and the preheating temperature is lower 20-30 degrees centigrade than the decomposition temperature of organic ingredients in the tail gas, and thus the method is safe and steady and no coking is occurred.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

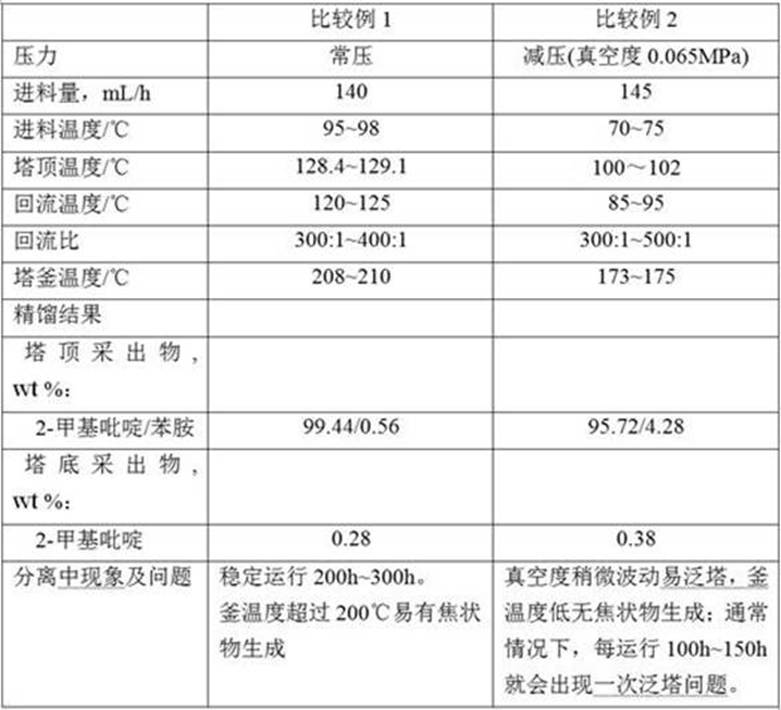

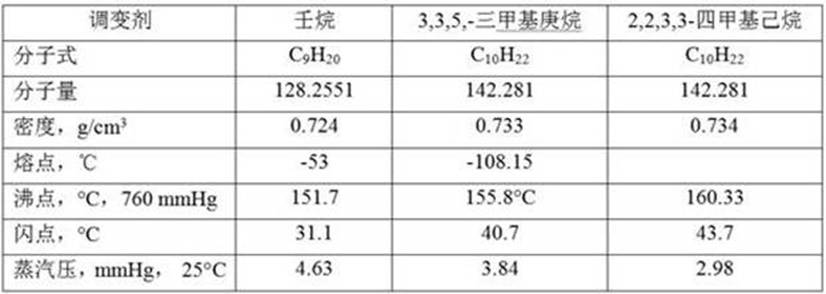

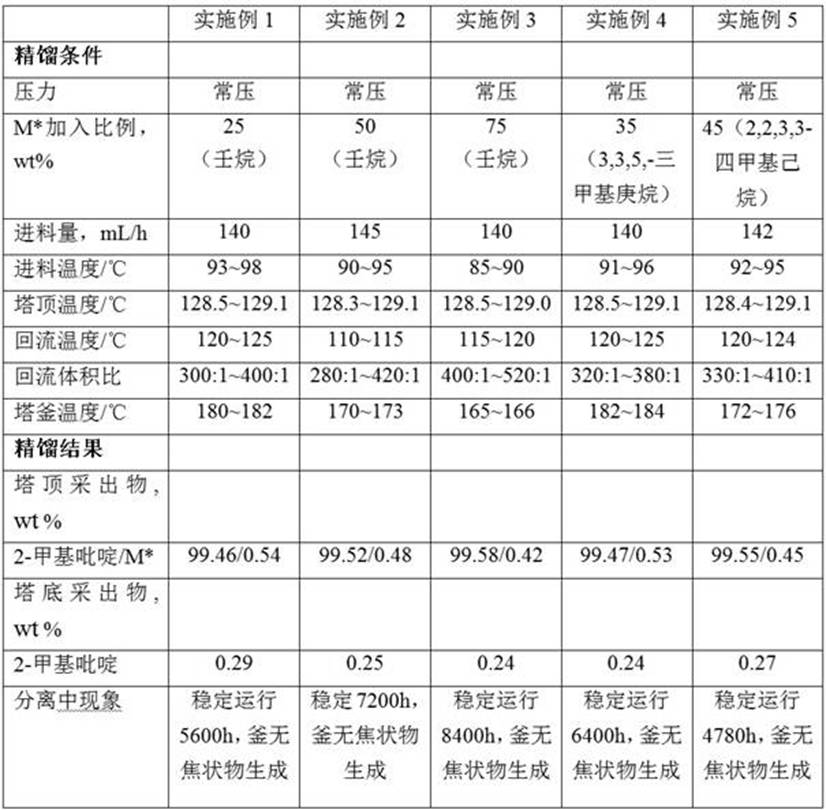

Separation method of 2-methylpyridine

PendingCN114685362AAdjustable temperatureReduce the temperatureAmino compound purification/separationMethylpyridiniumProcess engineering

The invention discloses a method for separating 2-methylpyridine. The method comprises the following steps: selecting a modulation agent M, wherein the modulation agent is a non-polar substance; the boiling point of the modulating agent is 130-183 DEG C; adding the modulating agent M into a separation raw material of a 2-methylpyridine separation tower according to a certain proportion; the obtained separation raw material enters a 2-methylpyridine separation tower, rectification is carried out under the rectification condition, and 2-methylpyridine with the increased concentration is obtained on the tower top. The method provided by the invention realizes the purposes of operation under normal pressure and reduction of the temperature of the tower kettle, and reduces the risk of coking of the tower kettle at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for upgrading lignin heavy oil to prepare bio-oxygenated fuel

ActiveCN110093179BImprove natureEfficient catalytic hydrogenation upgradingLiquid carbonaceous fuelsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen pressure

The invention discloses a method for preparing biological oxygenated fuel through lignin heavy oil upgrading. For technical problems of high oxygen content, low pH value and other characteristics of existing lignin heavy oil and inactivated catalysts caused by easy coking during bio-oil modification, the method mixes the lignin heavy oil and a non-noble metal catalyst supported by reaction media and alkaline carriers to perform reaction for 1-5 h at a temperature of 120-160 DEG C under a condition of 1-4 MPa hydrogen pressure, so that a catalyst can be separated, and the reaction media can beremoved, and therefore, the efficient catalytic upgrading of the lignin heavy oil can be realized, and high-grade bio-oxygenated fuel can be obtained; and pH values and calorific values can be increased, and oxygen content, oxygen to carbon atomic ratio and other key performance can be reduced. The method has significant advantages of being cheap and easy in catalyst obtaining, mile in reaction condition and obvious in lignin heavy oil performance enhancement, and can realize recycling; and the method is simple in technology operation and can realize intermittent and continuous production.

Owner:SOUTH CHINA UNIV OF TECH

Method for synthesizing citric acid ester type compound

InactiveCN101830803BHigh catalytic activityRich sourcesOrganic compound preparationCarboxylic acid esters preparationChemical synthesisSynthesis methods

The invention discloses a method for synthesizing a citric acid ester type compound, which belongs to the technical field of chemical synthesis. The method comprises the following steps of: using citric acid and fatty alcohol as main raw materials, and using benzene sulfonic acid or amino benzene sulfonic acid as a catalyst; and performing esterification and the purification processes of acetylation, neutralization, washing, drying, distillation and the like. The catalyst has rich sources, a low cost and high activity, can be separated from an esterification liquid easily after the neutralization, is coke-free during the distillation, has less corrosion to equipment, and is safe and environment-friendly; the water generated by the esterification is separated out by adopting a binary heterogeneous separation technique, and no water separating agent is additionally added; and acetyl citric acid ester is produced by adopting an esterification-acetylation continuous synthesis method, the flow is greatly simplified, and a synthesis process is shortened. The citric acid ester prepared by the method has the advantages of high quality, high purity, low degree of color and wide applicationrange.

Owner:NORTHWEST NORMAL UNIVERSITY

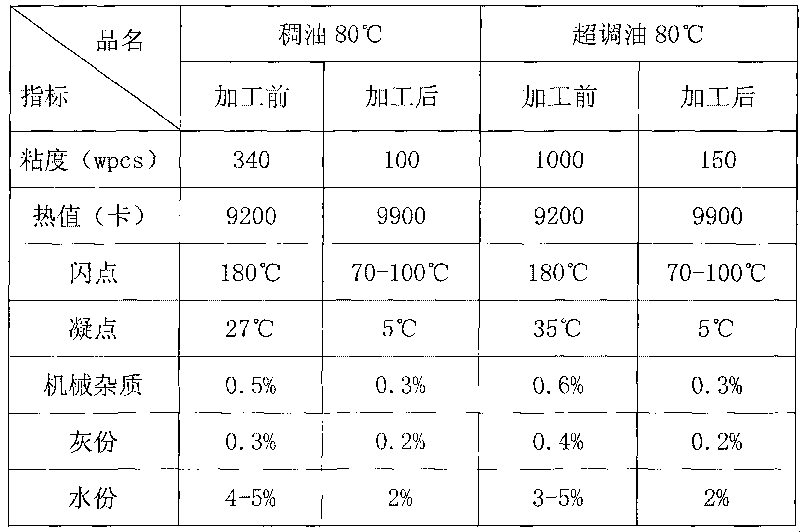

Heavy oil auxiliary

InactiveCN101747959AQuality improvementHigh calorific valueLiquid carbonaceous fuelsFuel additivesBiodieselCombustion

The invention discloses a heavy oil auxiliary, which is formed by stirring 18%-30% (by weight) of 0# diesel, 10%-20% of biodiesel, 8%-12% of viscosity reducer, 8%-12% of decomposer, 12%-15% of smoke remover, 10%-15% of naphthenic acid and 5%-8% of stabilizer for 3.5-4.5 hours at 70 to 100 DEG C, wherein the addition weight of heavy oil during the processing accounts for 0.5% of the weight of heavy oil to be processed. The heavy oil auxiliary is capable of greatly enhancing the quality of the processed heavy oil and bringing the heavy oil to sufficient combustion, thereby reducing air pollution and being favorable for environmental protection.

Owner:倪江波

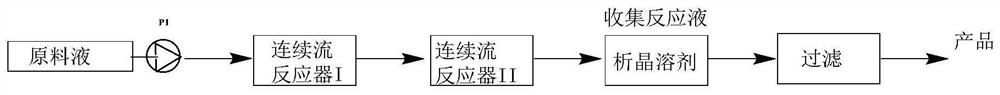

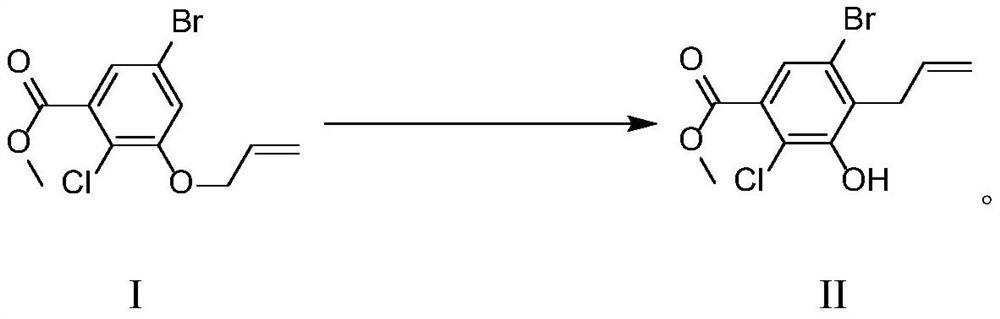

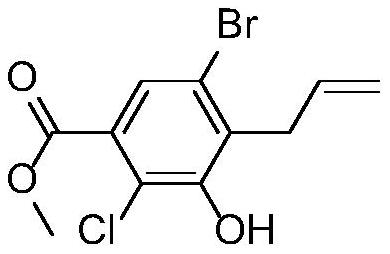

Preparation method of SGLT2 inhibitor intermediate

PendingCN113200860AReduce usageEasy to recycleOrganic compound preparationCarboxylic acid esters preparationBenzoic acidMetaclazepam

The invention provides a method for preparing an SGLT2 inhibitor intermediate through a continuous flow reaction. The SGLT2 inhibitor intermediate shown in the formula II is obtained by performing a a Claisen rearrangement reaction on 4-allyl-5-bromine-2-chloro-3-methyl hydroxybenzoate as a raw material for 5-20 minutes in a continuous flow tubular reactor I at the temperature of 180-250 DEG C, and then carrying out cooling, crystallization and filtering. The method for synthesizing the key intermediate of the SGLT2 inhibitor through the continuous flow reaction is stable and feasible in process, low in cost, high in yield, high in reaction rate, simple and convenient to operate, safe and environment-friendly, and has a huge practical value in the aspect of improving the production efficiency.

Owner:ASTATECH CHENGDU BIOPHARM CORP

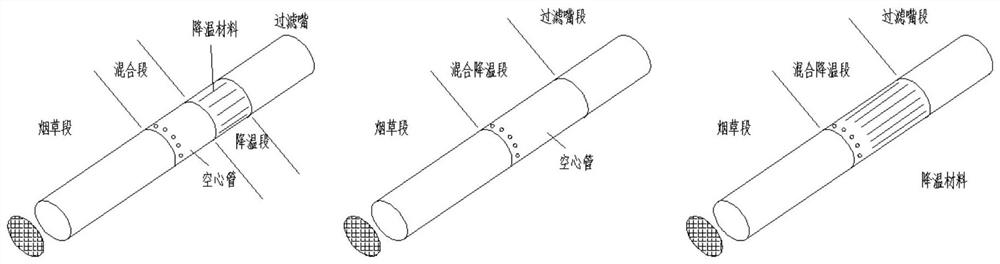

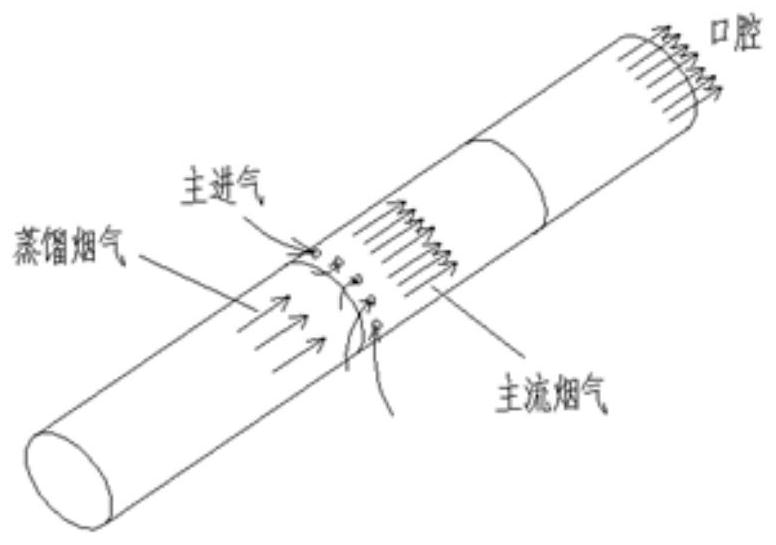

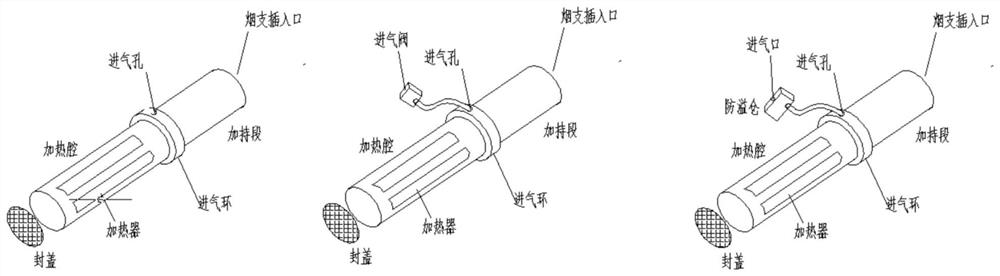

Novel smoke generating device and cigarette

The invention discloses a smoke generating device, which is mainly composed of a heating cavity, an air inlet ring, a cigarette clamping section and a cigarette inlet. After a cigarette is inserted into a heater, a tobacco section corresponds to the heating cavity, a mixed cooling section corresponds to the clamping section, and an air inlet hole corresponds to the air inlet ring; due to the continuity of heating, the smoke is maintained to continuously overflow from the tobacco material and enter the mixed cooling section space of the cigarette; and the smoke in the mixed cooling section is taken out by the intake airflow generated by suction and enters the oral cavity.

Owner:梅林

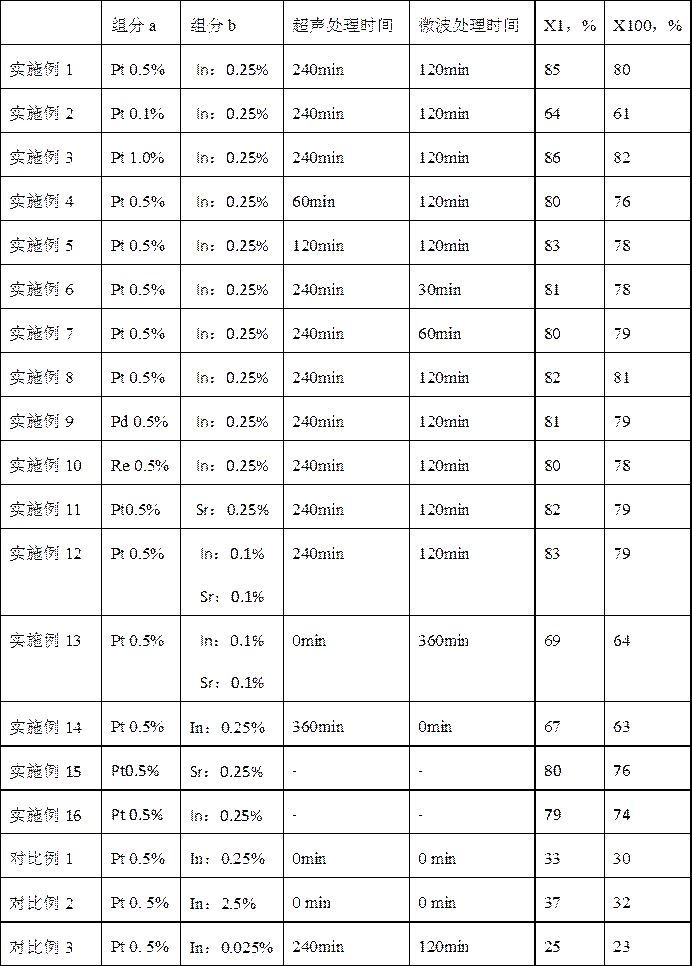

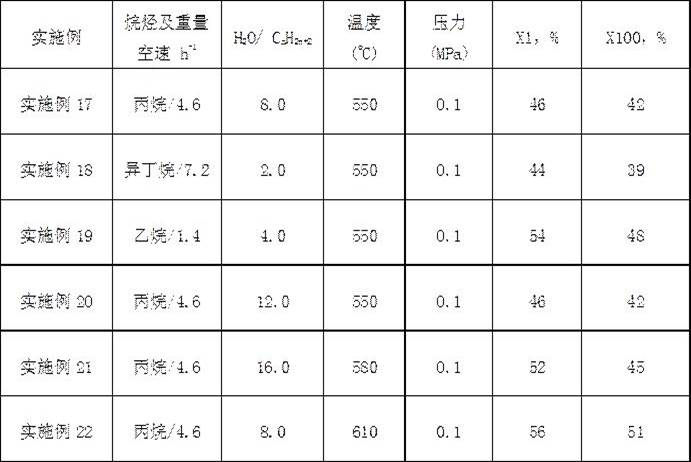

Highly dispersed dehydrogenation catalyst, preparation method and use method

The invention discloses a highly dispersed dehydrogenation catalyst, a preparation method and a method of use, comprising the following contents: the highly dispersed dehydrogenation catalyst is composed of (a) 0.1-5 parts of active components, (b) 0.1-2 parts of selected from subgroups At least one metal element or a metal oxide thereof in the element, (c) 95 to 99.9 parts of graphene materials are composed; the catalyst preparation method is as follows: the graphene is dispersed in an organic solvent, the metal salt of the active component is introduced, stirred and mixed. A certain amount of reducing agent is added, followed by microwave treatment, and the obtained insoluble matter is filtered, washed and dried to obtain a highly dispersed dehydrogenation catalyst. The catalyst has high metal dispersion, small size, and no acidity of the carrier, and has high activity and high stability when used in the dehydrogenation of low-carbon alkanes or the dehydrogenation of organic liquid hydrogen storage materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

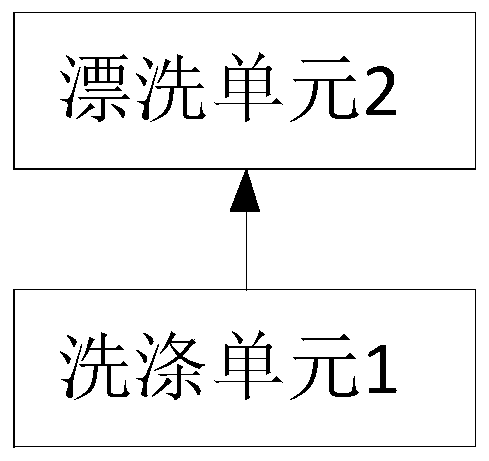

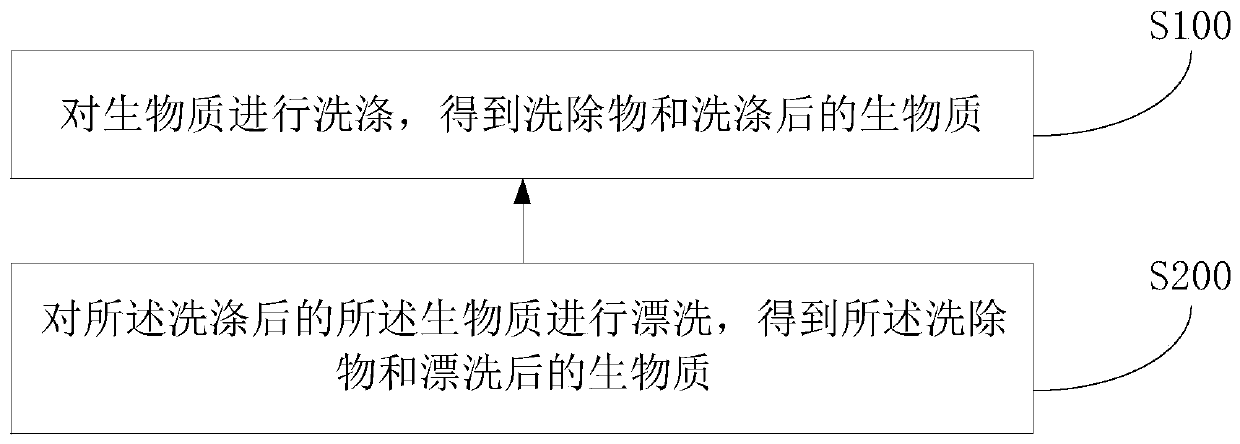

Biomass fuel pretreatment equipment and pretreatment method

InactiveCN111592923AImprove separation efficiencyNo slaggingBiofuelsSolid fuelsPretreatment methodCoke

The invention provides biomass fuel pretreatment equipment and method. The biomass fuel pretreatment equipment comprises a washing unit which is used for washing biomass, and obtaining an eluate and washed biomass; and a rinsing unit which is used for rinsing the washed biomass to obtain a washed substance and rinsed biomass, wherein the rinsed biomass is used as a material for preparing biomass fuel, and the eluent is used as a biogas material for generating biogas. The biomass is washed and rinsed to separate a material flow from an energy flow to realize ptimal use of things, organic matters are eluted from the biomass, impurities and potassium, chlorine, sulfur and nitrogen influencing fuel combustion are removed, and the unit heat value and the fuel quality of the fuel are improved sothat the fuel does not slag, coke or corrode a stove in the combustion process, high-quality fuel can be output to a user, the washed material flow is used as one part of a biogas raw material, afteranaerobic fermentation, a fertilizer is formed and returned to the field, and the ecological cycle of resources is completed.

Owner:吉林宏日新能源股份有限公司

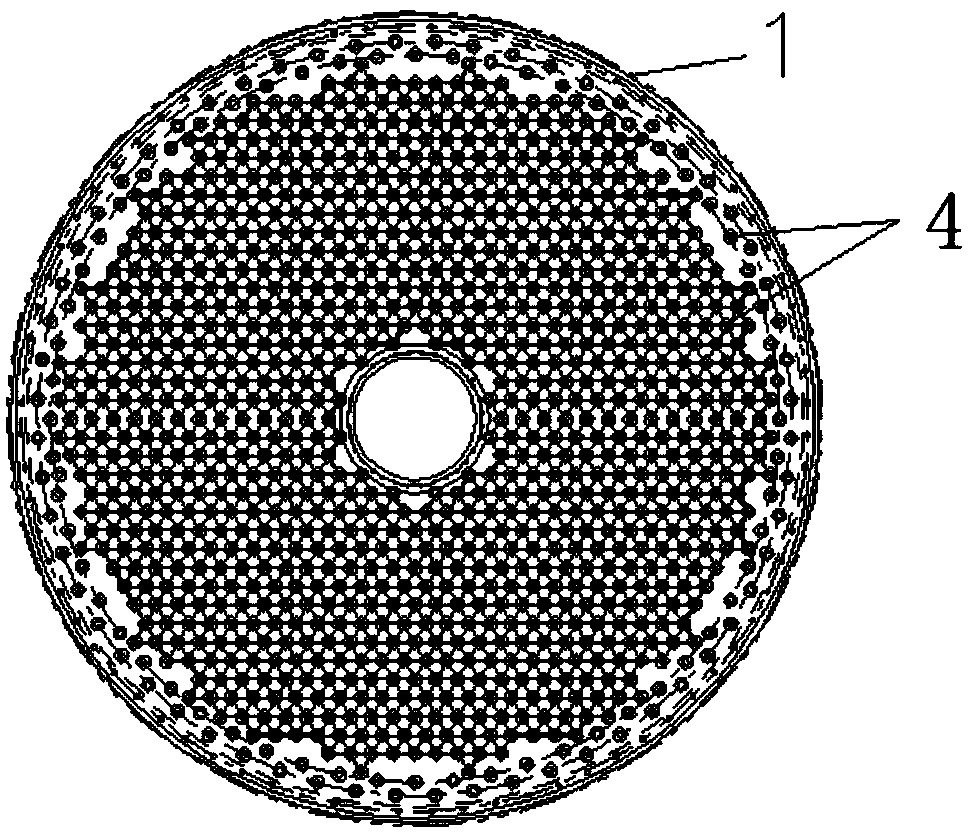

An oil tank heater with a valve

The invention discloses an oil tank heater with a valve. The oil tank heater comprises a shell, a heating component and a valve structure, wherein the heating component comprises a plurality of heating tube bundles and a heater head which is used for fixing the heating tube bundles, and the valve structure is arranged at the tail of the shell; the valve structure comprises a front fixed base, a back fixed base and a movable valve body, the front fixed base and the back fixed base are respectively located on both sides of an oil suction port, and the front fixed base is located between the back fixed base and the heater head; and the movable valve body is located between the front fixed base and the back fixed base, a threaded hole is formed in the front end of the movable valve body, a driving screw is installed on the front fixed base, one end of the driving screw is matched with the threaded hole, a bulge clamping structure is arranged on the other end of the driving screw, a driving shaft penetrates through the heater head, a driving handle is arranged on the outer end of the driving shaft, the inner end of the driving shaft extends to the front fixed base, and a groove which is matched with the bulge clamping structure is formed in the inner end of the driving shaft.

Owner:SHANDONG PULILONG PRESSURE VESSEL

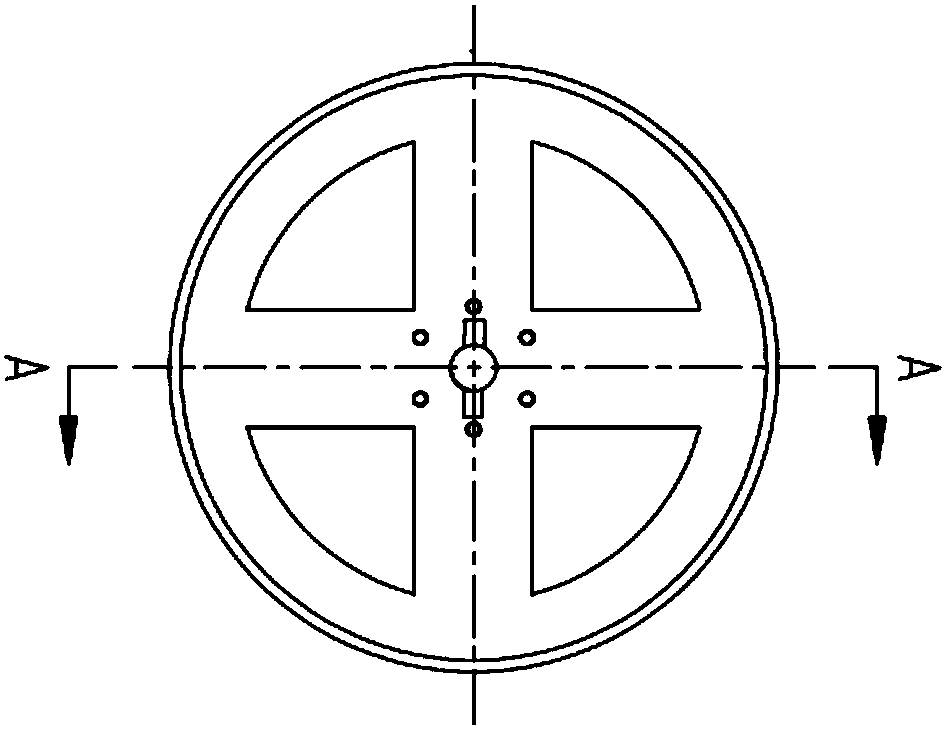

A hydrogenation reactor feed distributor and its feed process, design method and application

ActiveCN107661735BEvenly distributedNo erosionHydrocarbon oils refiningChemical/physical processesCompound (substance)Engineering

The invention relates to a feeding distributor for hydrogenation reactor as well as a feeding process, design method and use of the feeding distributor, belonging to the fields of oil-refining chemical engineering and coal chemical engineering. The feeding distributor comprises a feeding hole, a feeding distribution disc, rising pipes and rising pipe bubble covers, wherein the feeding distributiondisc is arranged above the feeding hole, each rising pipe is arranged on a through hole of the feeding distribution disc, and the diameters of rising pipe channels gradually decrease from bottom to top; and the upper parts of the rising pipes are packaged by the rising pipe bubble covers, horizontal notches communicated to the rising pipe bubble covers are formed in the side surface of the upperparts of the rising pipes, and outlets are formed in the bottom ends of the rising pipe bubble covers. By combining a feeding process of the feeding distributor with a whole set of equipment, the feeding speed and the flow state are controlled in a reasonable range, the fed materials are not deposited and coked, and meanwhile, a runner is not scoured.

Owner:CATECH TECH

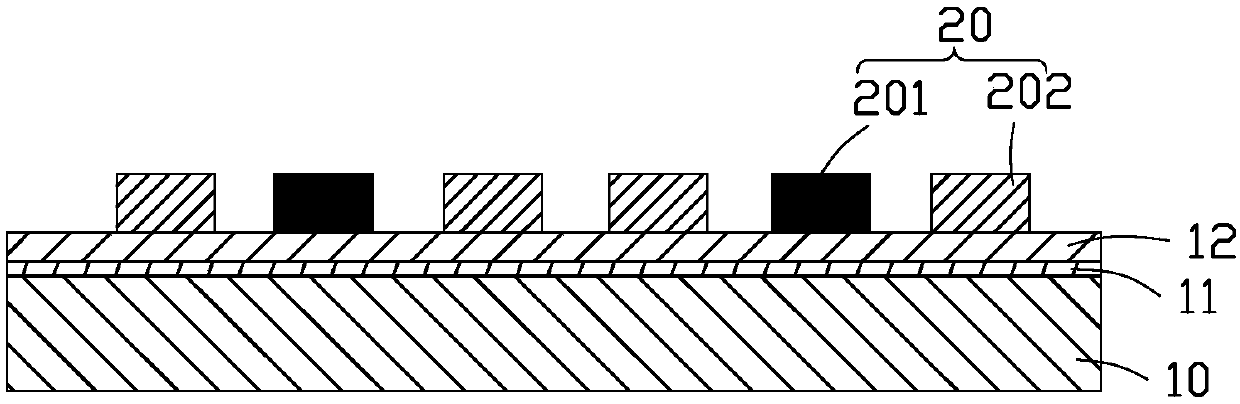

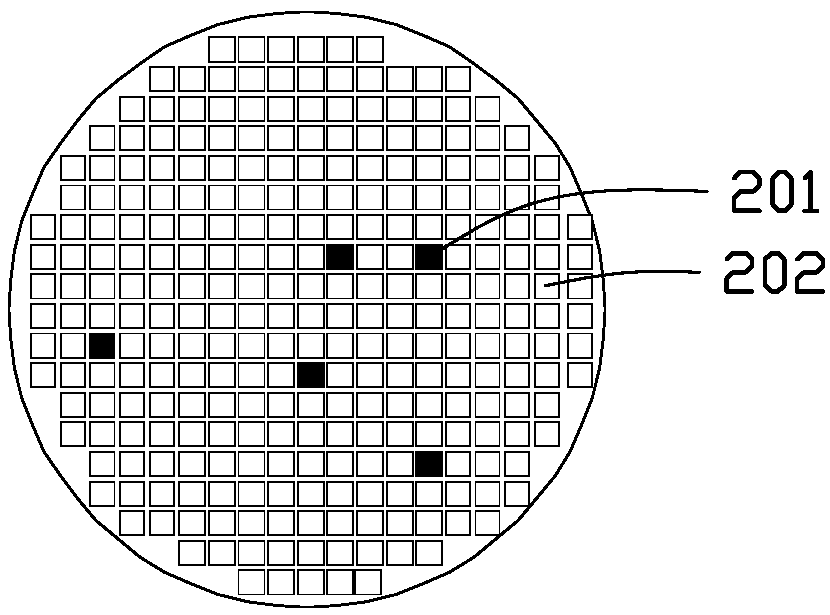

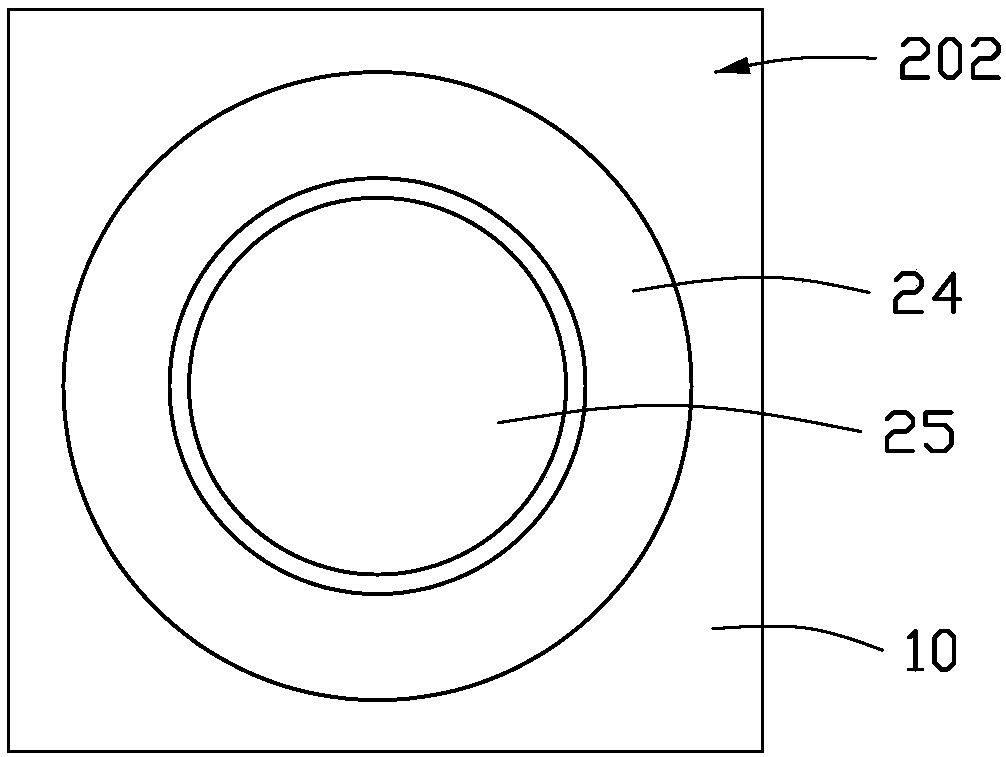

Manufacturing method of light-emitting diode micro-crystal grains

InactiveCN109755370AEasy to separateNo cokingSemiconductor devicesLight-emitting diodeBlocking layer

The invention relates to a manufacturing method of light-emitting diode micro-crystal grains. The method comprises the following steps of providing a substrate, wherein a buffer layer is formed on thesubstrate, and a laser blocking layer is formed on the surface of the buffer layer; forming array-arranged light-emitting diode micro-crystal grains on the laser blocking layer; providing an auxiliary substrate, and forming an adhesive layer on the auxiliary substrate; enabling the surface, having the adhesive layer, of the auxiliary substrate to be pressed to the light-emitting diode micro-crystal grains, wherein the gaps between the light-emitting diode micro-crystal grains are filled with the adhesive layer, and the adhesive layer is cured; performing irradiating on the substrate from thebottom surface of the substrate to enable the buffer layer to be gasified, wherein the substrate is separated from the laser blocking layer; performing etching on the substrate to remove the substrate; and performing dispergation on the adhesive layer so as to obtain a plurality of light-emitting diode micro-crystal grains.

Owner:ZHANJING TECH SHENZHEN +1

Method for preparing 2-amido-8-naphthol-6-sulfonic acid

InactiveCN101182301BImprove liquidityReduce power consumptionSulfonic acid preparationState of artAmmonia

The present invention relates to a method of preparing for 2-amido-8naphthol-6-sulfonic acid. The method considers 2-naphthylamine-6, 8-disulfonic acid or a salt thereof as the raw material to react with alkaline solution under the condition of stirring and then to be sent into a pressure reaction vessel for the pressure alkali fusion under the state without ammonia, and finally, after the temperature decrease, alkali fusion liquid is acidified by acid to obtain the target product of the 2-amido-8naphthol-6-sulfonic acid. Compared with the prior art, a reaction system of the present inventiontechnology has good fluidity, little power consumption, no coking, the high purity of the product and little pollution to the environment, and the product is not required to be refined and can be used for the synthesis of high-grade dye and organic pigment directly.

Owner:浙江海晨化工有限公司

A kind of thick syrup of brown sugar beverage and production method thereof

The invention relates to a concentrated brown sugar beverage and a production method thereof, belonging to the field of sugar processing. The concentration of the thick syrup of brown sugar drink is 72-75 ° Bx, including the following mass fraction ingredients: 0.01-0.05% carrageenan, 0.01-0.05% xanthan gum, 0.01-0.05% sucrose ester, 2-8 fructooligosaccharides % and glyceryl monostearate 0.01‑0.02%. The product of the invention is not easy to stratify, maintains a good product shape and a long shelf life, has the functions of regulating intestinal flora, proliferating bifidobacteria, and promoting the absorption of calcium, improving the health effect of the product, and also has In terms of food, it has the characteristics of fast dissolution, convenient quantification and rich nutrition. It is a very promising brown sugar product.

Owner:云南滇王驿农业科技开发有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com