An oil tank heater with a valve

A heater and oil tank technology, applied in the field of oil tank heaters, can solve the problems of working environment pollution, prolonging maintenance time, pollution, etc., and achieve the effects of increasing heat exchange area, reducing circulation area, and ensuring heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

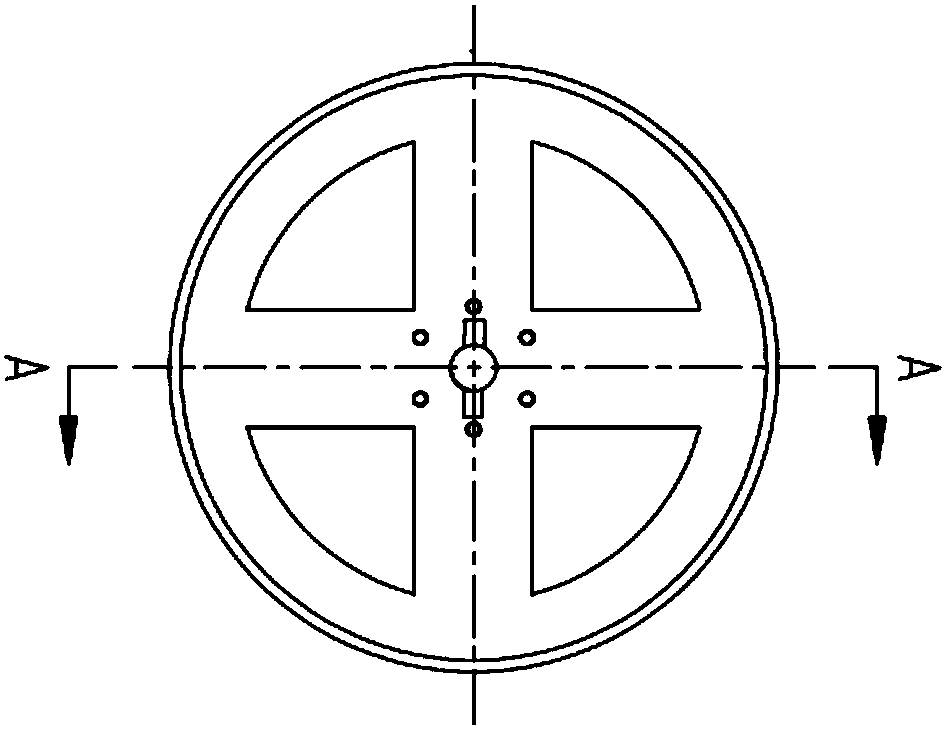

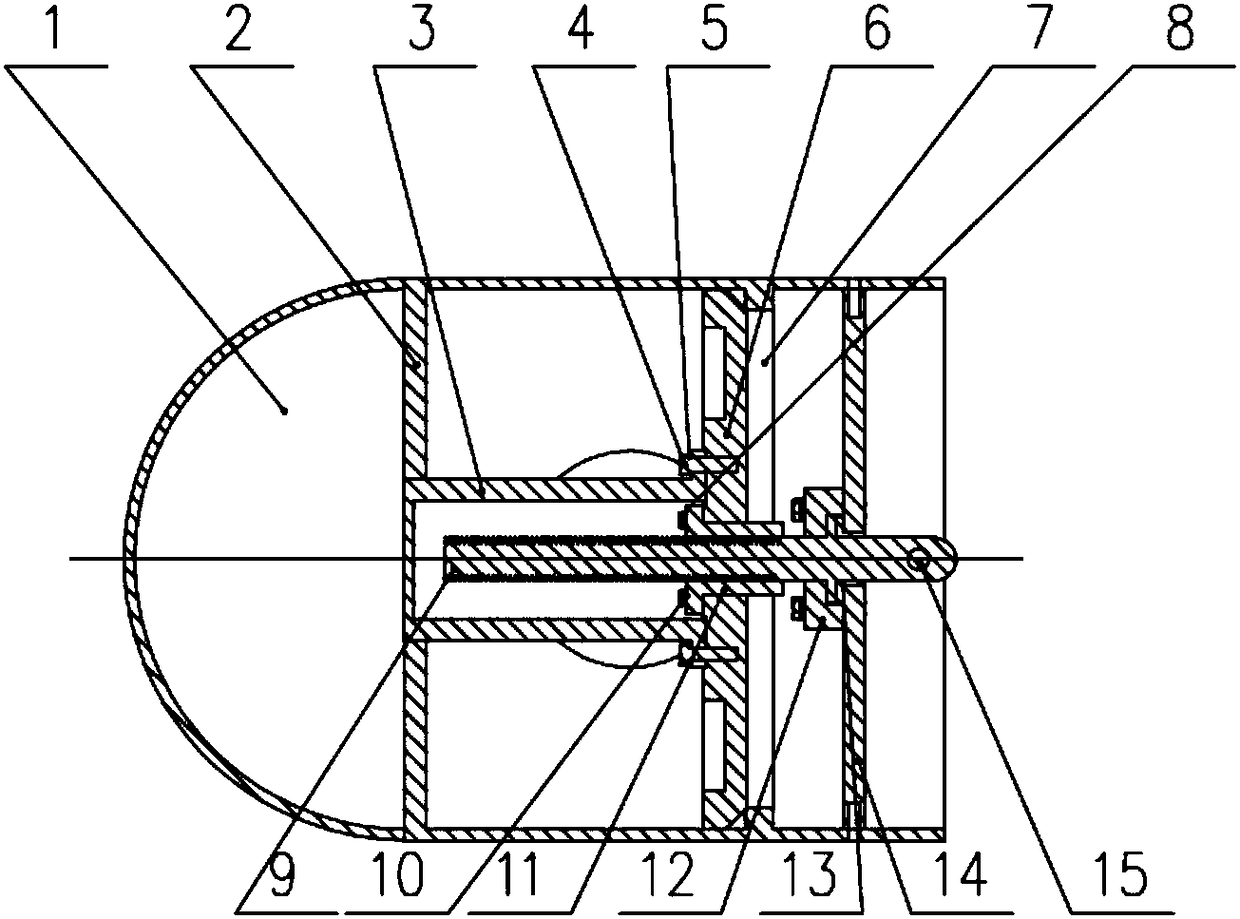

[0055] Such as figure 2 , image 3 and Figure 7 As shown, an oil tank heater with a valve includes a housing 19, a heating component and a valve structure. The heating component includes several heating tube bundles and a heater head 17 that fixes the heating tube bundle. The heater head and The housing 19 cooperates to fix the heating tube bundle inside the housing 19. The heating tube bundle is fixed together by a stainless steel cluster. The heater head 17 is provided with an oil outlet, and the tail of the housing is provided with an oil suction port. The valve The structure is arranged at the tail of the shell;

[0056] The valve structure includes a front fixed base 14, a rear fixed base 2 and a movable valve body. The front fixed base 14 and the rear fixed base 2 are respectively located on both sides of the oil suction port, and the front fixed base 14 is located at the rear fixed base. Between seat 2 and the heater head.

[0057] The movable valve body is positi...

Embodiment 2

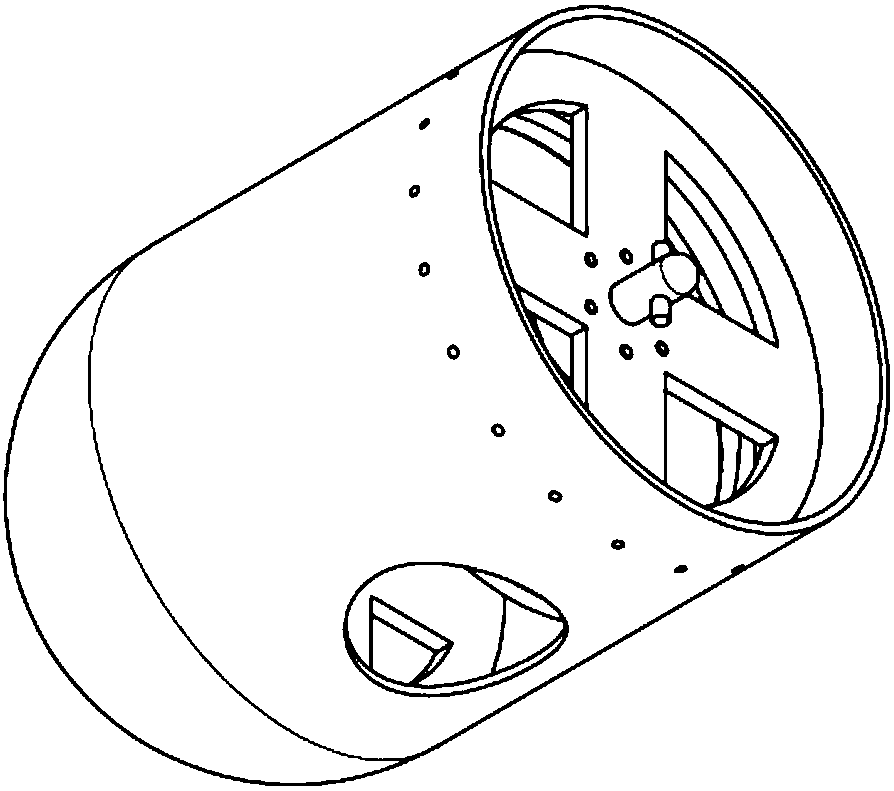

[0074] Such as Figure 4 , Figure 5 and Figure 6 As shown, the movable valve body includes a bottom and a side wall, the bottom has a hole, the side wall of the movable valve body is attached to the inner wall of the housing 19, and the side wall is provided with an opening corresponding to the oil suction port. , the length of the solid portion of the side wall is greater than the diameter of the oil suction port.

[0075] Shake the drive handle 16 to drive the drive shaft 18 to rotate, and then drive the transmission screw 9 to rotate, the movable valve body moves to the front fixed base 14 under the drive of the transmission screw 9, and the side wall of the movable valve body moves the heater shell The oil suction port of 19 is blocked, prevents that the oil in the oil tank flows out from the oil suction port.

[0076] After the heater has been repaired, the heater is installed in the oil tank, and the two are sealed, and the drive handle 16 is shaken to drive the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com