A hydrogenation reactor feed distributor and its feed process, design method and application

A technology of feed distributor and hydrogenation reactor, which is applied in chemical instruments and methods, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of deposition, erosion, blockage, etc. effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] This embodiment is applied to the oil-coal slurry bed hydrogenation process.

[0027] 1. Feed process:

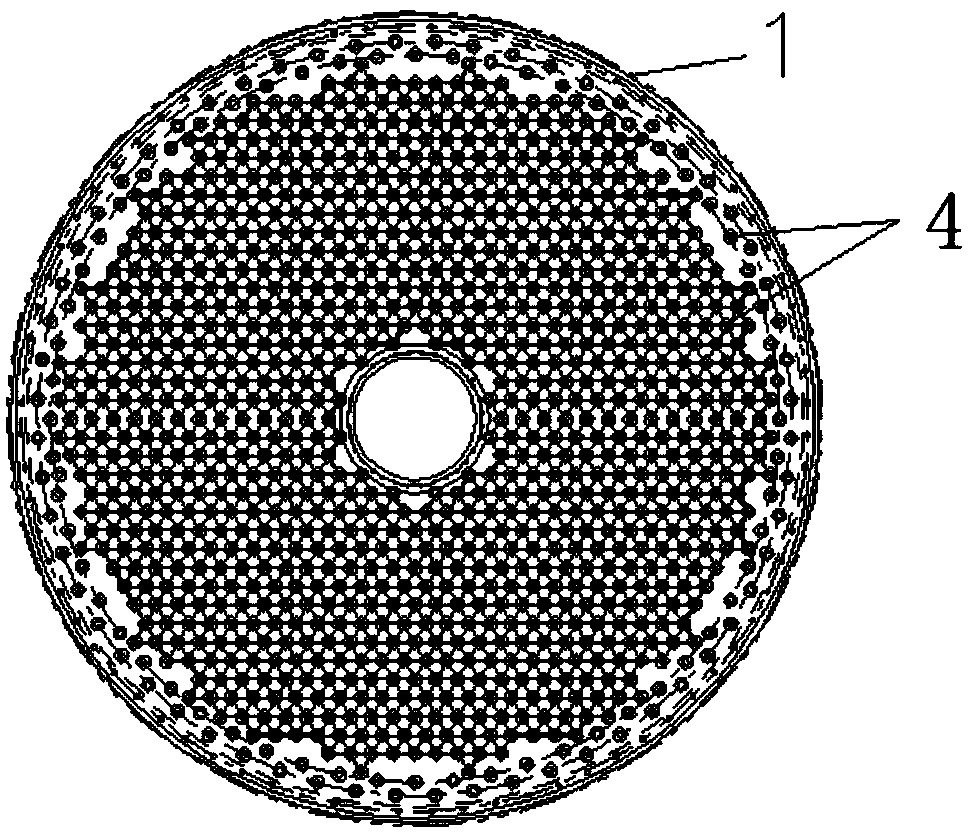

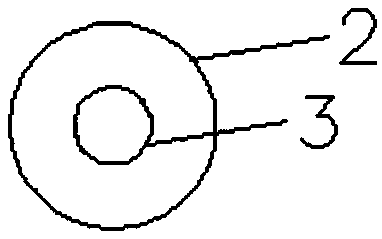

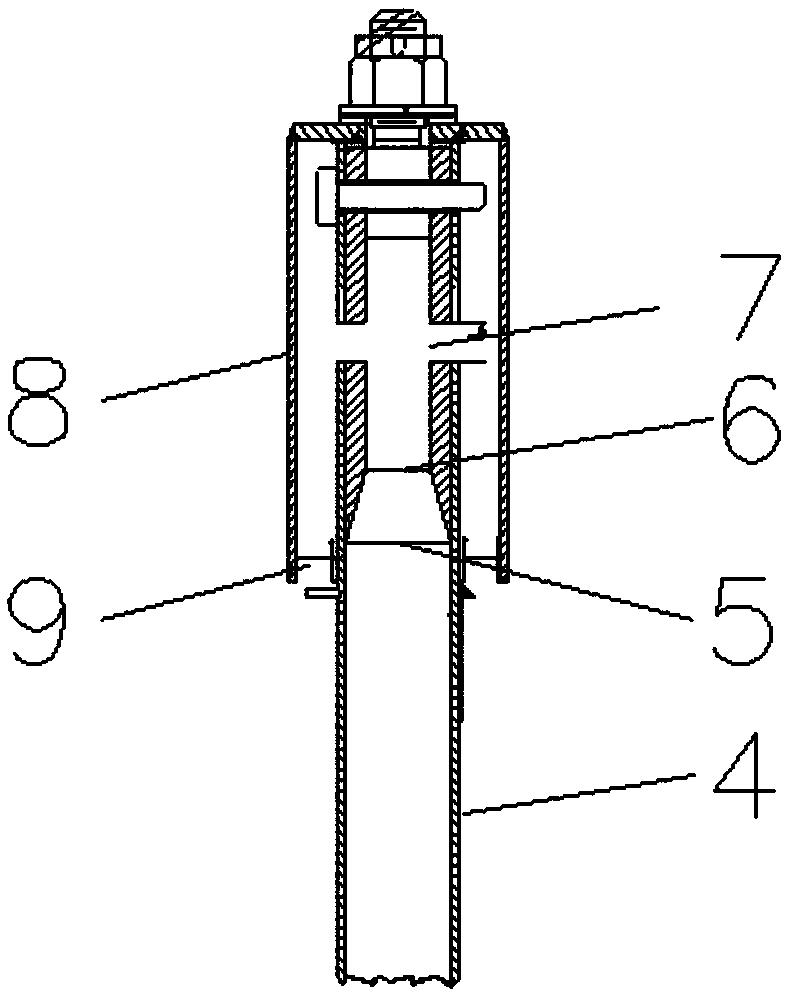

[0028] (1) if Figure 1-3 As shown, the oil-coal mixture first enters the reactor through the feed port, reaches the feed distribution plate 1 arranged in the feed port, and then enters the corresponding riser 4 above each hole on the feed distribution plate 1. The riser channel is The structure has a large inlet and a small outlet, and is surrounded by rising pipe blisters 8 on the outside. Four rising pipe horizontal cutouts 7 are set on the upper part of the rising pipe 4. The medium flows out from the horizontal cutouts 7. Four apertures at the lower end of the blister are the outlet 9 of the blister to flow out.

[0029] (2) The reactor has an internal circulation structure, and the circulation feed inlet enters the reactor vertically from the lower part, and the flow process is the same as that of fresh feed. In this embodiment, the reactor barrel, feed inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com