Method for preparing 2-amido-8-naphthol-6-sulfonic acid

A technology of naphthol and sulfonic acid, which is applied in the chemical field to achieve the effects of less power consumption, good fluidity and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

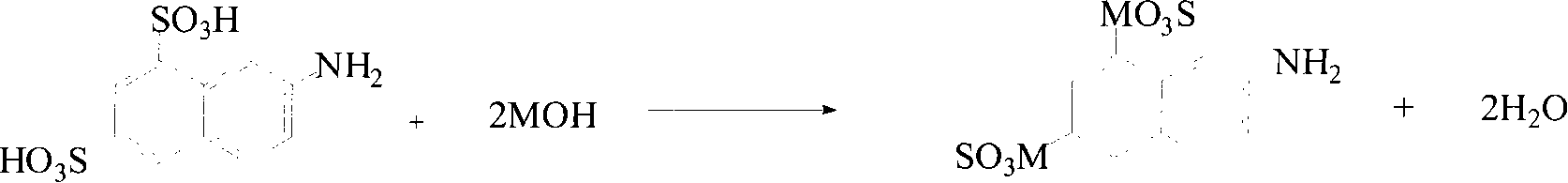

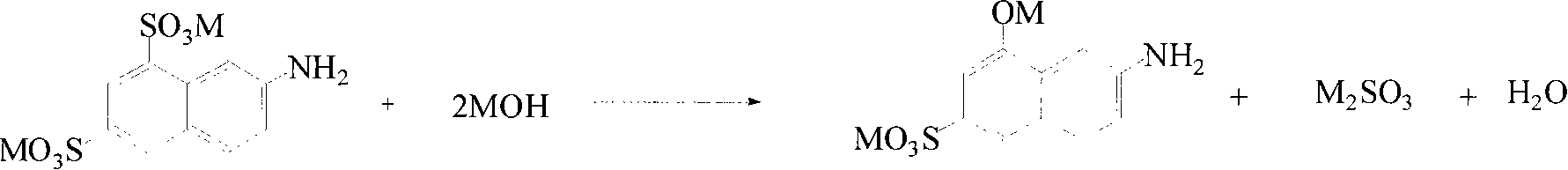

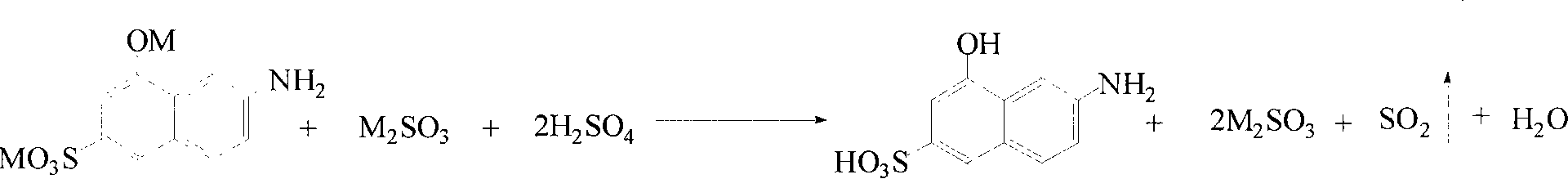

Method used

Image

Examples

Embodiment 1

[0024] Add the water of 900L in the concentration pot, start to stir, add the sodium hydroxide of 600 kilograms 96%. After sodium hydroxide all dissolved, add the amino G salt of 1200 kilograms in batches. Afterwards, the temperature is raised to catch the ammonia and concentrate, and the ammonia gas produced is recovered by the ammonia gas recovery system. When ammonia no longer escapes, add 1000 kilograms of 96% sodium hydroxide, then, transfer to the autoclave, and seal the autoclave. Continue to raise the temperature to 195-200°C, keep the temperature for 10 hours, and keep the pressure at 0.2-0.5Mpa. After the heat preservation is over, transfer the alkali melt to the acid analysis pot, acidify it with 30-50% sulfuric acid at 80-90°C to pH ≤ 1, and drive out SO at 90-100°C 2 1-2 hours, SO 2 into the recycling system. Finally, lower the temperature to 50-55°C for filtration, wash the filter cake with warm water, drain it, and dry it to obtain the finished product of g...

Embodiment 2

[0026] Add 4220 kilograms of 30% sodium hydroxide into the concentration pot, and add 1200 kilograms of amino G salt in batches when the temperature is raised to 70-80°C while stirring. Afterwards, the temperature is raised to catch the ammonia and concentrate, and the ammonia gas produced is recovered by the ammonia gas recovery system. When the ammonia gas no longer escapes, continue to concentrate until the sodium hydroxide content is 35-40%, then transfer to the autoclave, and seal the autoclave. Continue to raise the temperature to 195-200°C, keep the temperature for 10 hours, and keep the pressure at 0.2-0.5Mpa. After the heat preservation reaction is over, transfer the alkali melt to the acid analysis pot, acidify it with 30-50% sulfuric acid at 80-90°C to pH ≤ 1, and drive out SO at 90-100°C 2 1-2 hours, SO 2 into the recycling system. Finally, lower the temperature to 50-55°C for filtration, wash the filter cake with warm water, drain it, and dry it to obtain the ...

Embodiment 3

[0028] Add 3165 kg of 30% sodium hydroxide into the concentration pot, and add 1200 kg of amino G salt in batches when stirring and heating up to 70-80°C. Afterwards, the temperature is raised to catch the ammonia and concentrate, and the ammonia gas produced is recovered by the ammonia gas recovery system. When ammonia no longer escapes, add 492 kilograms of 90% potassium hydroxide, and continue to concentrate to a content of 35-40% (in sodium hydroxide), then, transfer to the autoclave, and seal the autoclave. Continue to raise the temperature to 195-200°C, keep the temperature for 6 hours, and keep the pressure at 0.2-0.5Mpa. After the heat preservation is over, transfer the alkali melt to the acid analysis pot, acidify it with 30-50% sulfuric acid at 80-90°C to pH ≤ 1, and drive out SO at 90-100°C 2 1-2 hours, SO 2 into the recycling system. Finally, lower the temperature to 50-55°C for filtration, wash the filter cake with warm water, drain it, and dry it to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com