Circulating fluidized bed boiler and flow state reconstruction method suitable for high-viscosity flue gas

A circulating fluidized bed, high-viscosity technology, used in fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, to reduce wear, reduce steel consumption, and improve ash separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

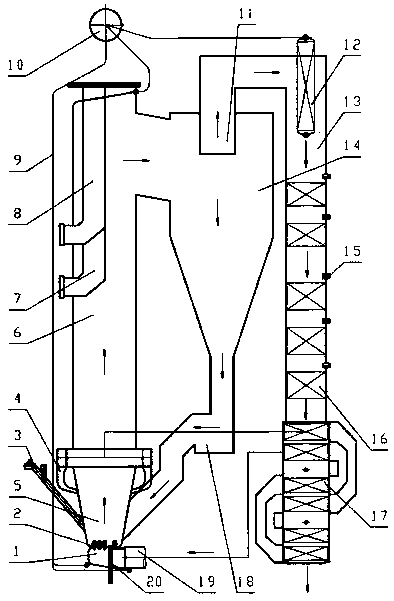

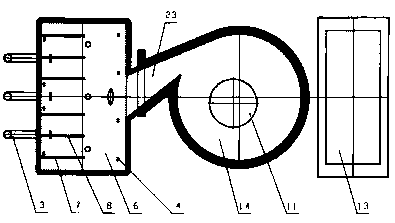

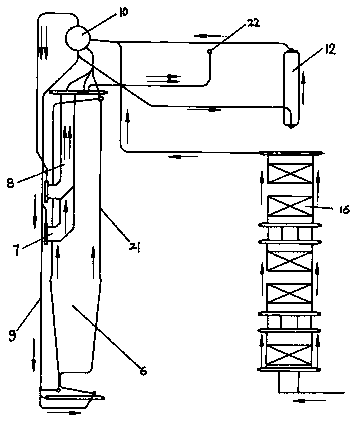

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

[0024]A circulating fluidized bed boiler adapted to high viscosity flue gas, including primary air chamber 1, air distribution plate and air cap 2, coal feeding device 3 in front of furnace, secondary hot air branch pipe 4, fluidized bed combustion chamber 5, furnace 6, Water cooling panel 7, centralized downpipe 9, boiler barrel 10, central barrel 11, tail shaft flue 13, high temperature cyclone separator 14, economizer 16, air preheater 17, low energy consumption self-balancing return valve 18, ignition The device 19 and the slag removal pipe 20 are provided with a superheating screen 8 in the furnace 6, and a convective evaporation tube bundle 12 is arranged on the upper part of the tail shaft flue 13. 12 communicates with the boiler drum 10 through a water guide pipe, and the drum 10 communicates with the overheating panel 8 through another water guide tube. A high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com