Environment-friendly preparation technology for producing 2-naphthol by liquid phase alkali fusion method

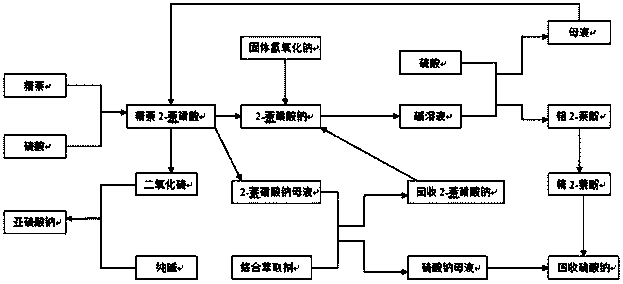

A preparation process and a liquid-phase alkali technology are applied in the field of environmental protection preparation technology for producing 2-naphthol by a liquid-phase alkali fusion method, which can solve the problems of secondary pollution, high use risk, easy coking and the like, and achieve zero emission and heating. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Add 1420 parts of refined naphthalene to the sulfonation kettle using traditional techniques, heat to 120°C, add 98% sulfuric acid and heat up to 160°C for sulfonation. After reaching the end point, blow naphthalene and dilute with alkali And, filter to obtain sodium 2-naphthylsulfonate, add it to 3000kg (content 32%) of sodium hydroxide, heat to about 320°C, react with alkali fusion for 2 hours, then dilute, neutralize, and separate 2-naphthol phenol The crude product was washed with water, dehydrated, distilled and sliced to obtain 1210kg of 2-naphthol with a yield of 91.18%.

Embodiment 2

[0021] Embodiment 2: production process is the same as embodiment 1, and alkali uses 3500kg (content 40%) potassium hydroxide solution instead, and alkali melting temperature is 280 ℃~290 ℃. Finally, 1250kg2-naphthol was obtained with a yield of 94.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com