Process and system for treating vinyl cyanide tail gas by high temperature burning method

A technology of acrylonitrile and incineration, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of increased processing cost, slow reaction rate of biological method, secondary pollution, etc., achieve safe and stable coking, save fuel consumption, No coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

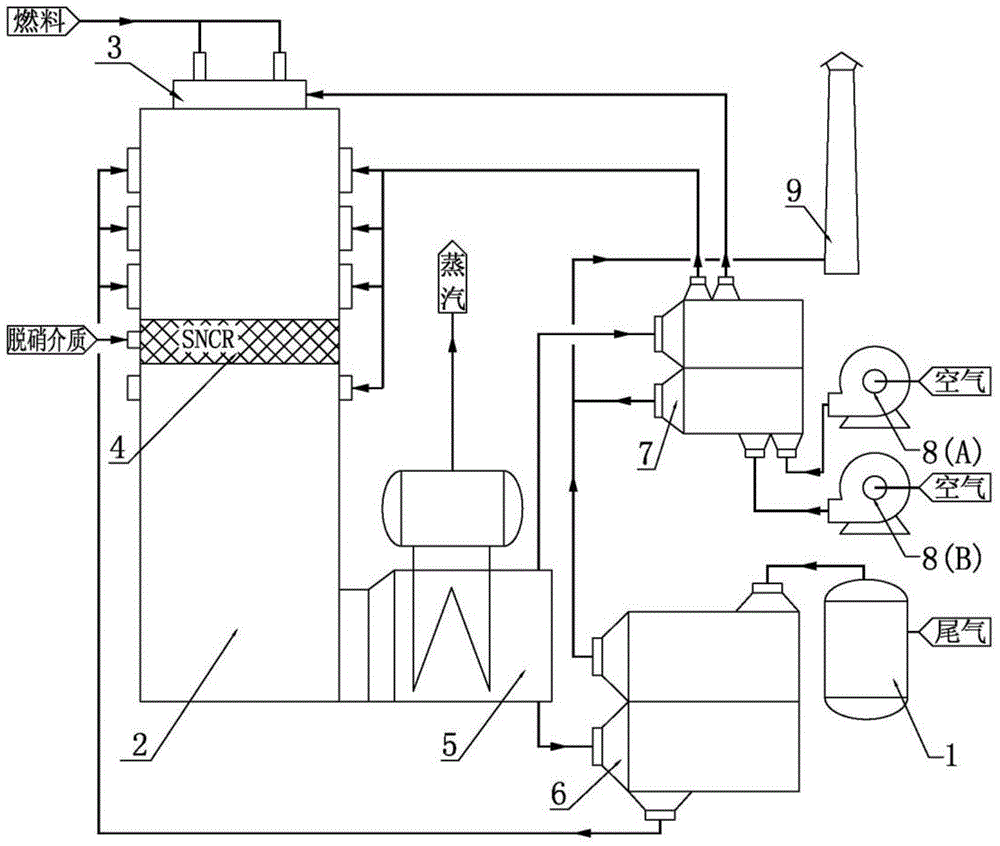

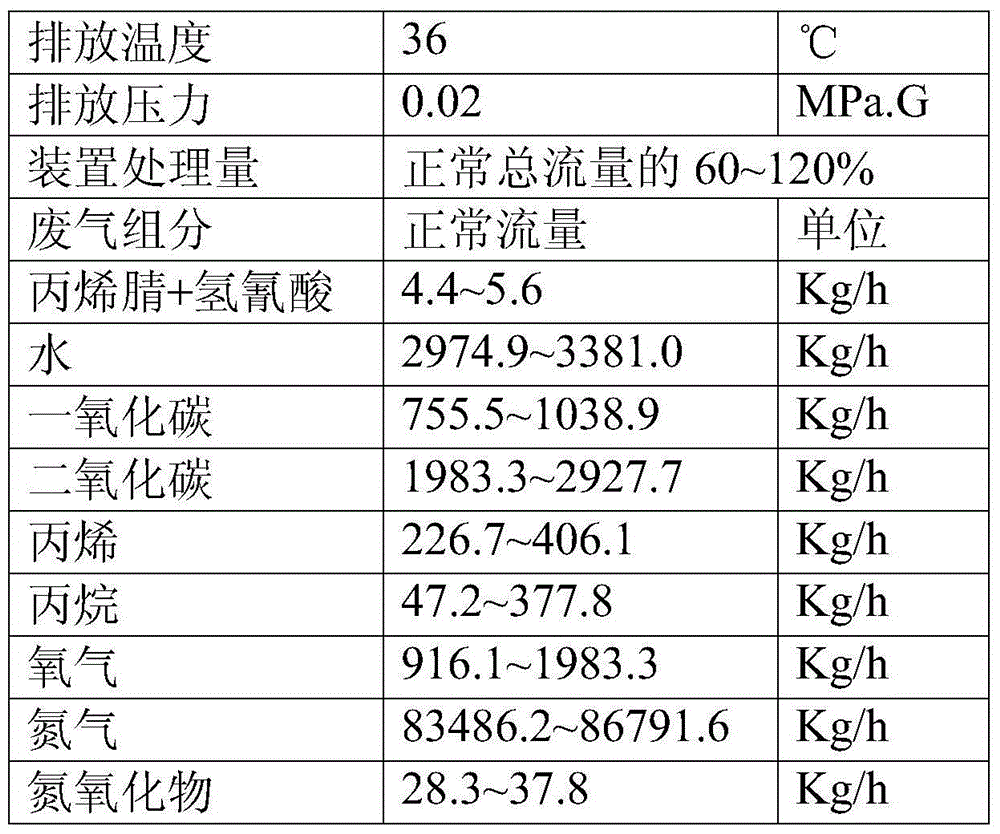

[0033] The composition and state parameters of the acrylonitrile tail gas to be treated are shown in the following table 1:

[0034]

[0035]

[0036] The steps of adopting the method of the present invention to process the above-mentioned acrylonitrile tail gas are as follows:

[0037] Step 1: The acrylonitrile tail gas enters the gas-liquid separation tank 1, and the condensate in the tail gas is separated and then transported to the acrylonitrile tail gas-flue gas heat exchanger 6 through a pipeline for preheating. The preheating temperature is 450-500°C ;

[0038] Step 2: The blower 8 provides combustion-supporting air, which is first sent to the combustion-supporting air-flue gas heat exchanger 7 for preheating. The preheating temperature is 200-500°C. The preheated air is sent to the incinerator 2 and the combustion supporter 3 respectively. The temperature in the chamber of the incinerator 2 is adjusted by adjusting the flow rate of the fuel in the burner 3, and ...

Embodiment 2

[0043] The composition and state parameters of the acrylonitrile tail gas to be treated are shown in the following table 1:

[0044]

[0045]

[0046] The steps of adopting the method of the present invention to process the above-mentioned acrylonitrile tail gas are as follows:

[0047] Step 1: The acrylonitrile tail gas enters the gas-liquid separation tank 1, and the condensate in the tail gas is separated and then transported to the acrylonitrile tail gas-flue gas heat exchanger 6 through a pipeline for preheating. The preheating temperature is 450-500°C ;

[0048] Step 2: The blower 8 provides combustion-supporting air, which is first sent to the combustion-supporting air-flue gas heat exchanger 7 for preheating. The preheating temperature is 200-500°C. The preheated air is sent to the incinerator 2 and the combustion supporter 3 respectively. The temperature in the chamber of the incinerator 2 is adjusted by adjusting the flow rate of the fuel in the burner 3, and ...

Embodiment 3

[0053] The composition and state parameters of the acrylonitrile tail gas to be treated are shown in the following table 1:

[0054]

[0055]

[0056] The steps of adopting the method of the present invention to process the above-mentioned acrylonitrile tail gas are as follows:

[0057] Step 1: The acrylonitrile tail gas enters the gas-liquid separation tank 1, and the condensate in the tail gas is separated and then transported to the acrylonitrile tail gas-flue gas heat exchanger 6 through a pipeline for preheating. The preheating temperature is 450-500°C ;

[0058] Step 2: The blower 8 provides combustion-supporting air, which is first sent to the combustion-supporting air-flue gas heat exchanger 7 for preheating. The preheating temperature is 200-500°C. The preheated air is sent to the incinerator 2 and the combustion supporter 3 respectively. The temperature in the chamber of the incinerator 2 is adjusted by adjusting the flow rate of the fuel in the burner 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com