Method and system for incinerating iodine-containing organic waste liquor, purifying and treating tail gas

A technology for tail gas purification and organic waste liquid, which is applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as environmental hazards, increased oxidant consumption, and insufficient economy, and achieve resource and energy conservation, overcome limitations, and achieve cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

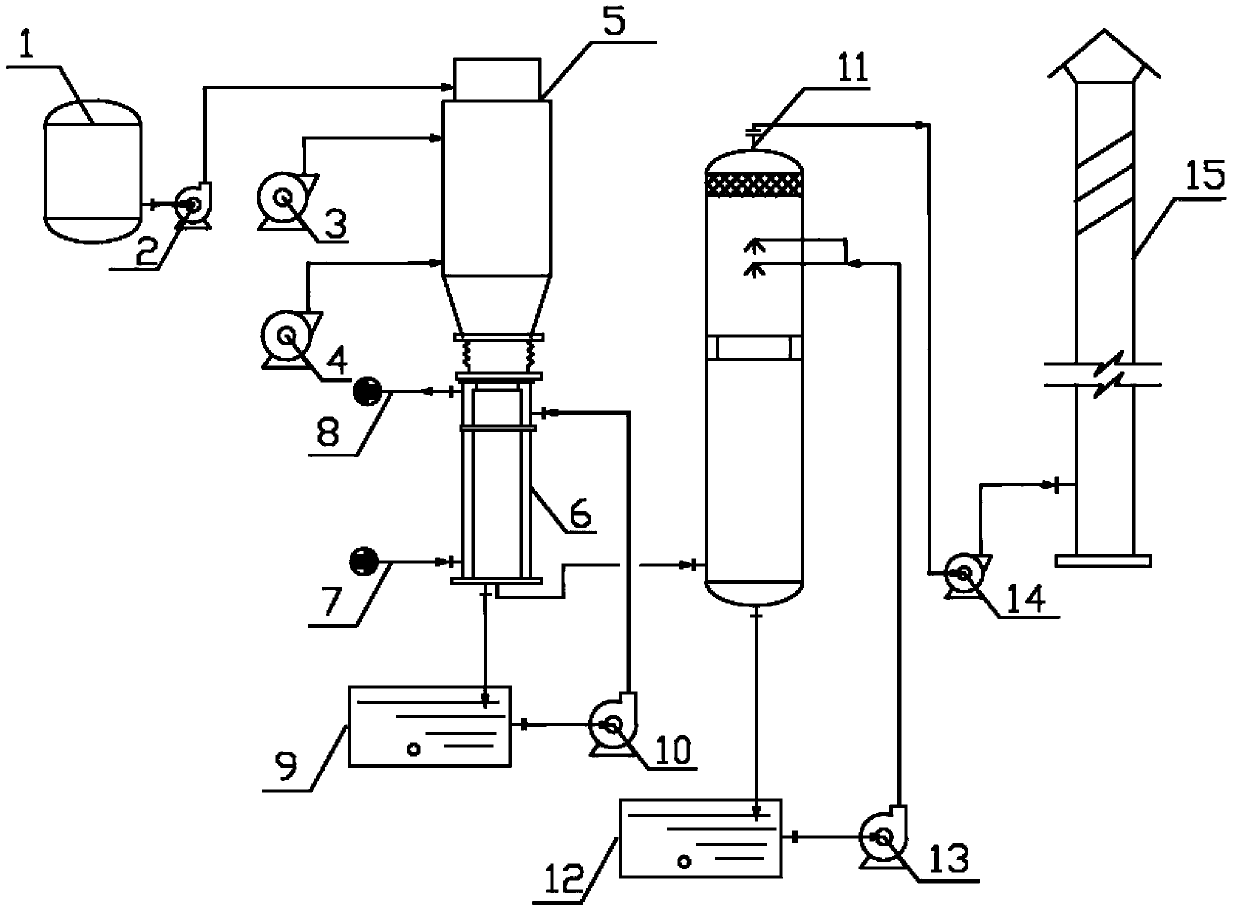

[0030] A kind of iodine-containing organic waste liquid incineration and exhaust gas purification treatment system provided by the present invention are introduced below in conjunction with accompanying drawing and embodiment:

[0031] Such as figure 1 As shown, an iodine-containing organic waste liquid incineration and tail gas purification treatment system is characterized in that it includes a waste liquid incineration system, a flue gas cooling system, a tail gas purification system and a tail gas discharge system, wherein a flue gas is installed below the waste liquid incineration system. Gas cooling system, the flue gas cooling system is connected to the exhaust gas purification system through the flue gas pipeline, and the exhaust gas purification system is connected to the exhaust gas discharge system through the flue gas pipeline.

[0032] A kind of iodine-containing organic waste liquid incineration and tail gas purification treatment system as described above, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com