Manufacturing method of light-emitting diode micro-crystal grains

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of not deep ablation of grains, difficulty in peeling off good-quality grains from semiconductor substrates, and excessive ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0038] The fabrication method of the light-emitting diode microcrystals provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] A method for manufacturing light-emitting diode microcrystals, comprising the steps of:

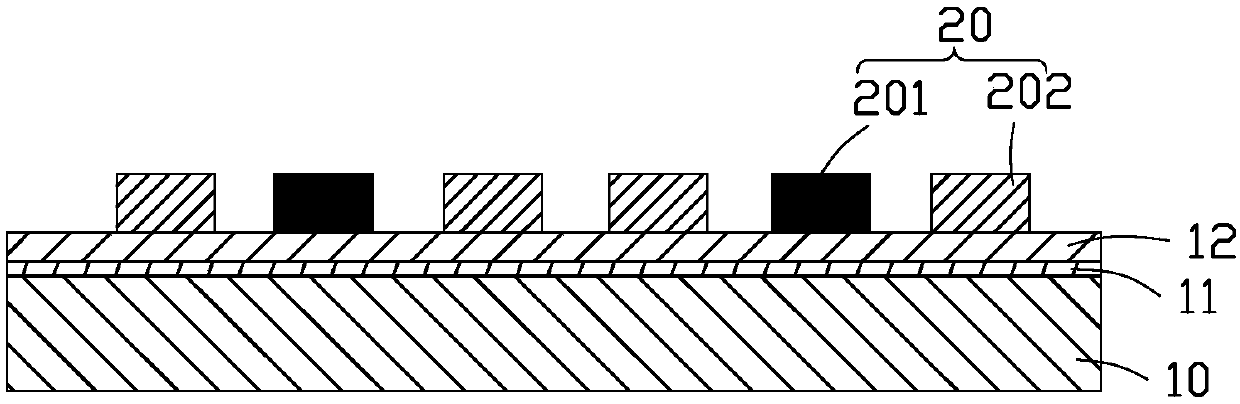

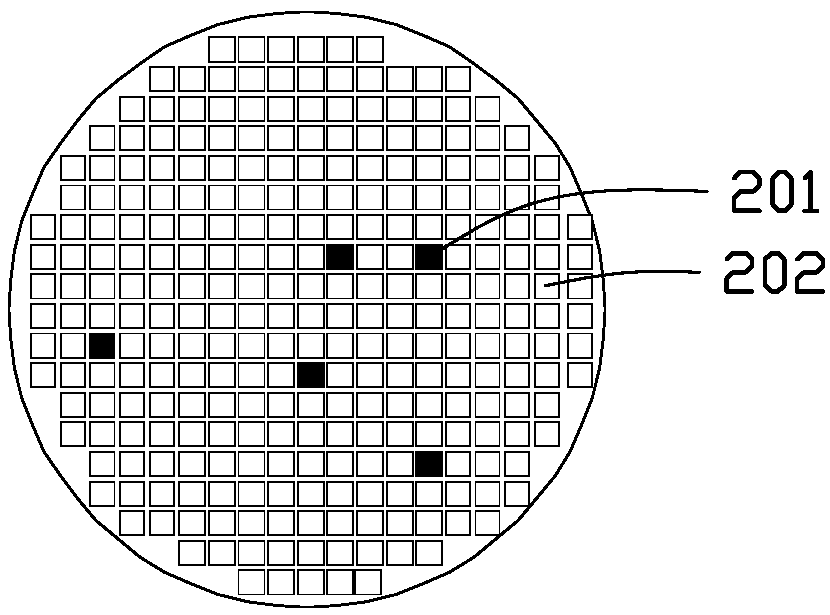

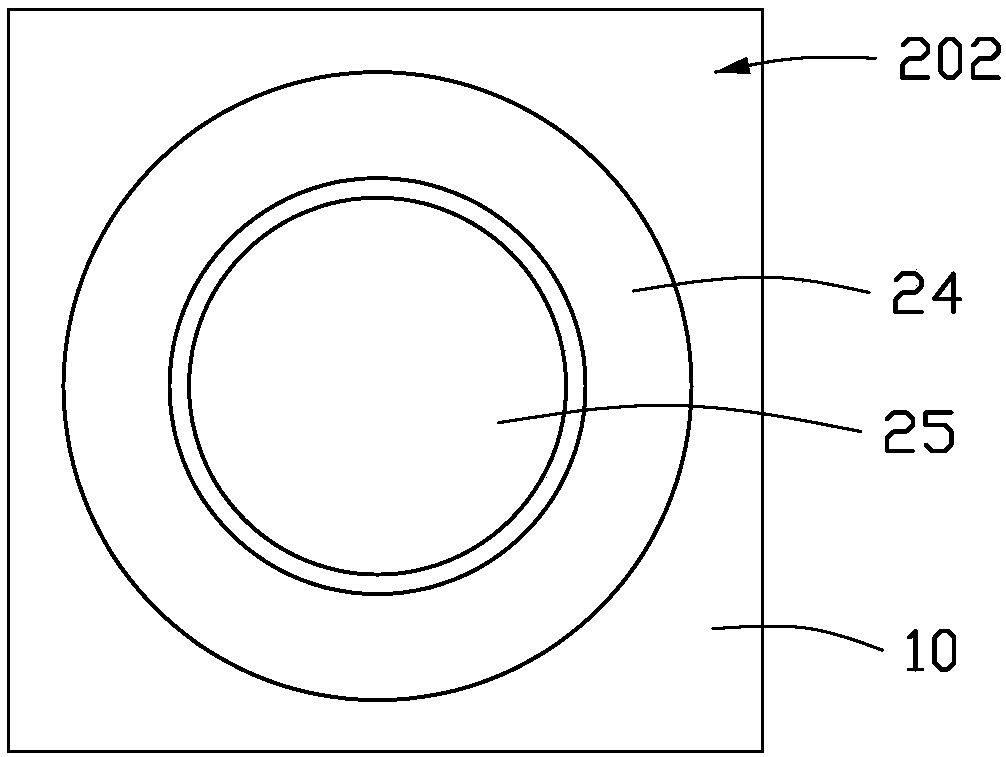

[0040] Step 1: See figure 1 A base substrate 10 is provided, a buffer layer 11 is formed on the base substrate 10 , and a laser blocking layer (UV blocking layer) 12 is formed on the surface of the buffer layer (Buffer Layer) 11 .

[0041] In this embodiment, the base substrate 10 is a sapphire substrate, and the buffer layer 11 and the laser blocking layer 12 are formed by metal organic chemical vapor deposition (MOCVD).

[0042] The material of the buffer layer 11 is aluminum nitride or gallium nitride, and the thickness of the buffer layer 11 is 10 nm to 50 nm, preferably, between 20 nm.

[0043] The material of the laser blocking layer 12 is doped gallium nitride or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com