High-dispersion dehydrogenation catalyst, and preparation method and use method of same

A dehydrogenation catalyst, highly dispersed technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. It can achieve the effect of high stability, high dispersion, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

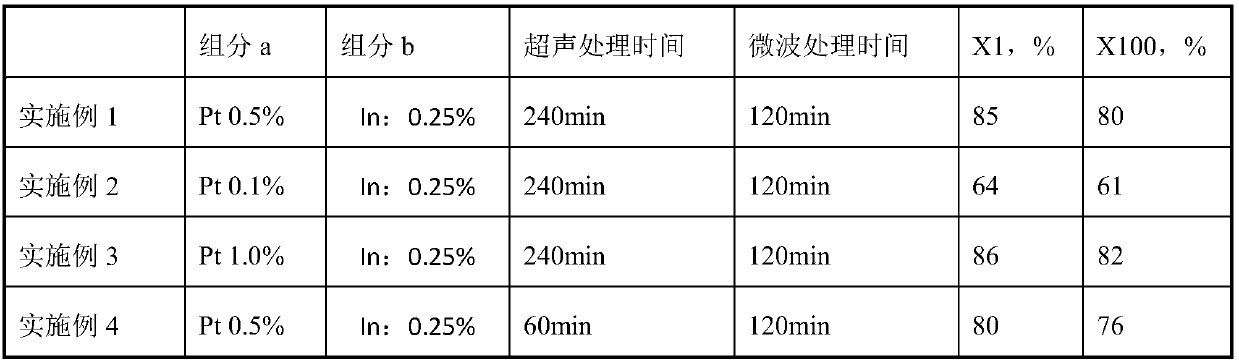

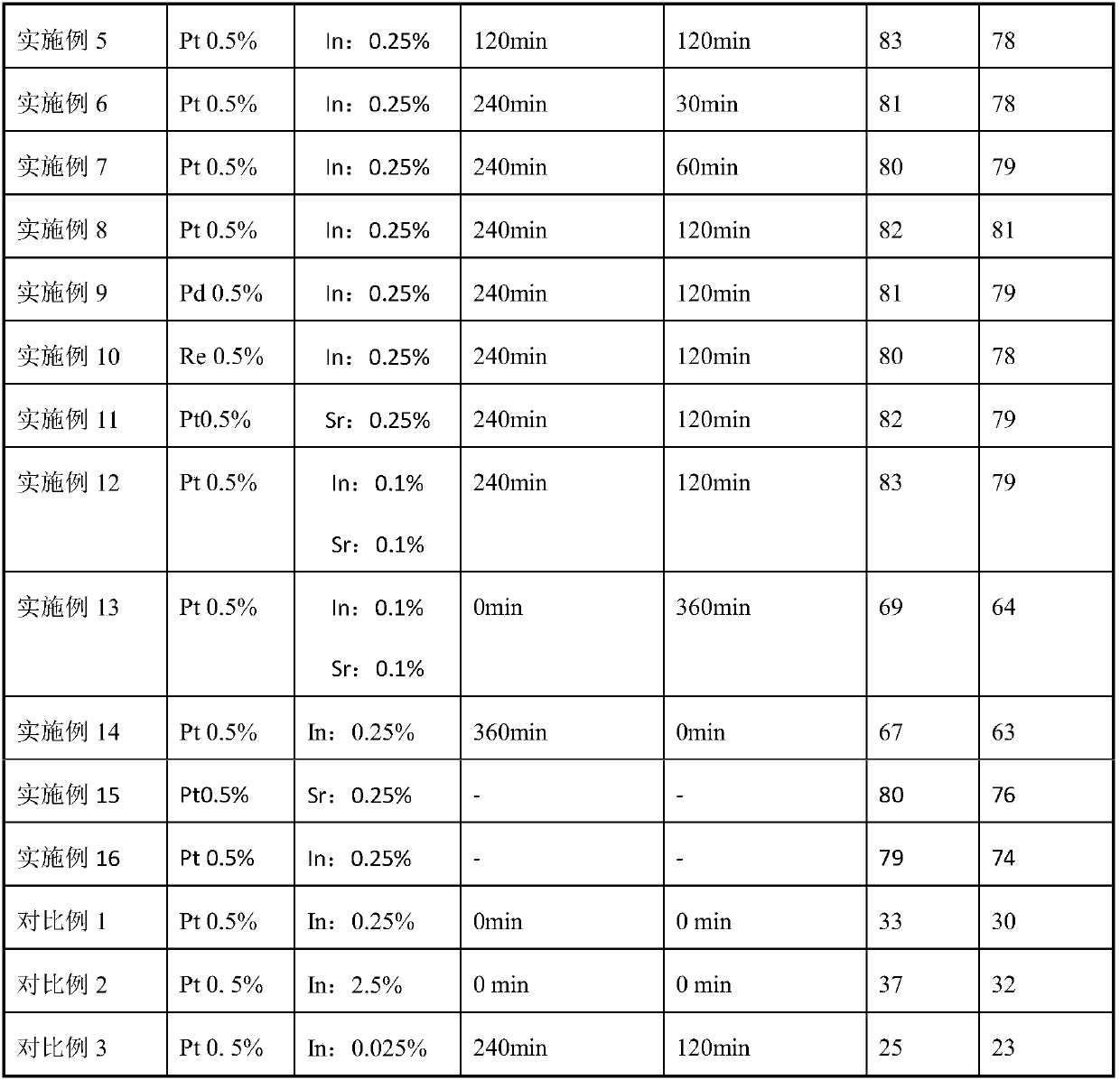

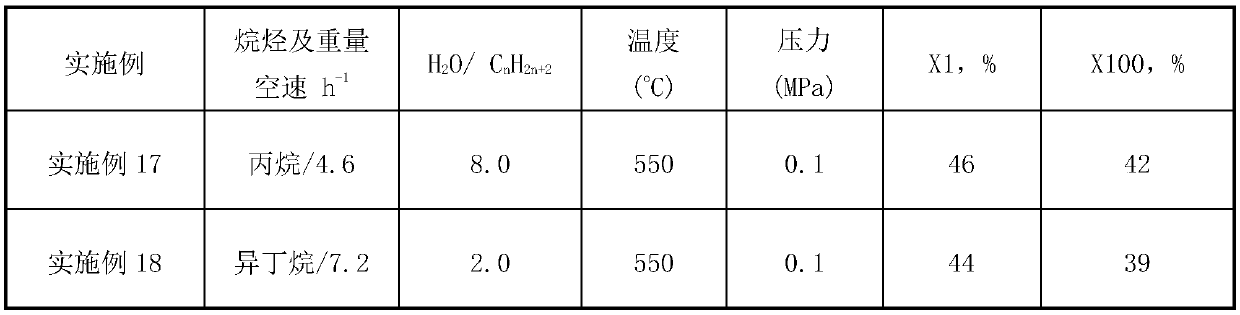

Examples

Embodiment 1

[0035] Weigh 2 g of graphene oxide, add it into 50 ml of ethylene glycol solution, and ultrasonicate for 240 min to obtain a dispersed graphene oxide solvent.

[0036] Take 0.622mL of a mixed solution of 16.14mL / L chloroplatinic acid and 8.03ml / L indium chloride, add 1.378mL of water to prepare a solution, add it to the graphene oxide solvent, stir it magnetically for 3 hours, then add 2ml of 0.2mol / L Sodium hydroxide / ethylene glycol solution, dried by microwave for 120min, then filtered, washed with ethanol several times, finally dried at 120°C for 4h, and put into a muffle furnace with He atmosphere at 350°C for 4h, Get a catalyst.

[0037] The obtained catalytic material is pressed and ground, and the selected particle size is 20-40 mesh, and 0.1 g is evaluated in an isothermal fixed-bed differential reactor. Before the evaluation, it is reduced with hydrogen. The reduction conditions are as follows: normal pressure, temperature 350 ℃, the hydrogen flow rate is 20mL / min, t...

Embodiment 2

[0040] Weigh 2 g of graphene oxide, add it into 50 ml of ethylene glycol solution, and ultrasonicate for 240 min to obtain a dispersed graphene oxide solvent.

[0041] Take 0.124mL of a mixed solution of 3.228mL / L chloroplatinic acid and 8.03ml / L indium chloride, add 1.378mL of water to make a solution, add it to the graphene oxide solvent, stir it magnetically for 3h, then add 2ml of 0.2mol / L Sodium hydroxide / ethylene glycol solution, dried by microwave for 120min, then filtered, washed with ethanol several times, finally dried at 120°C for 4h, and put into a muffle furnace with He atmosphere at 350°C for 4h, Get a catalyst.

[0042] The obtained catalytic material is pressed and ground, and the selected particle size is 20-40 mesh, and 0.1 g is evaluated in an isothermal fixed-bed differential reactor. Before the evaluation, it is reduced with hydrogen. The reduction conditions are as follows: normal pressure, temperature 350 ℃, the hydrogen flow rate is 20mL / min, the reduc...

Embodiment 3

[0044] Weigh 2 g of graphene oxide, add it into 50 ml of ethylene glycol solution, and ultrasonicate for 240 min to obtain a dispersed graphene oxide solvent.

[0045] Take 1.244mL of chloroplatinic acid with a concentration of 32.28mL / L and 8.03ml / L indium chloride mixed solution, add 1.378mL of water to make a solution, add it into the graphene oxide solvent, stir magnetically for 3h, then add 2ml of 0.2mol / L Sodium hydroxide / ethylene glycol solution, dried by microwave for 120min, then filtered, washed with ethanol several times, finally dried at 120°C for 4h, and put into a muffle furnace with He atmosphere at 350°C for 4h, Get a catalyst.

[0046] The obtained catalytic material is pressed and ground, and the selected particle size is 20-40 mesh, and 0.1 g is evaluated in an isothermal fixed-bed differential reactor. Before the evaluation, it is reduced with hydrogen. The reduction conditions are as follows: normal pressure, temperature 350 ℃, the hydrogen flow rate is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com