Electron source device and display

An electron source, conductive layer technology, applied in image/graphic display tubes, cathode ray tubes/electron beam tubes, circuits, etc., can solve the problems of difficulty in making large flat-panel display devices, shortened lifespan, and pollution of CN, etc. Uniform electron emission ability, avoid direct contact, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

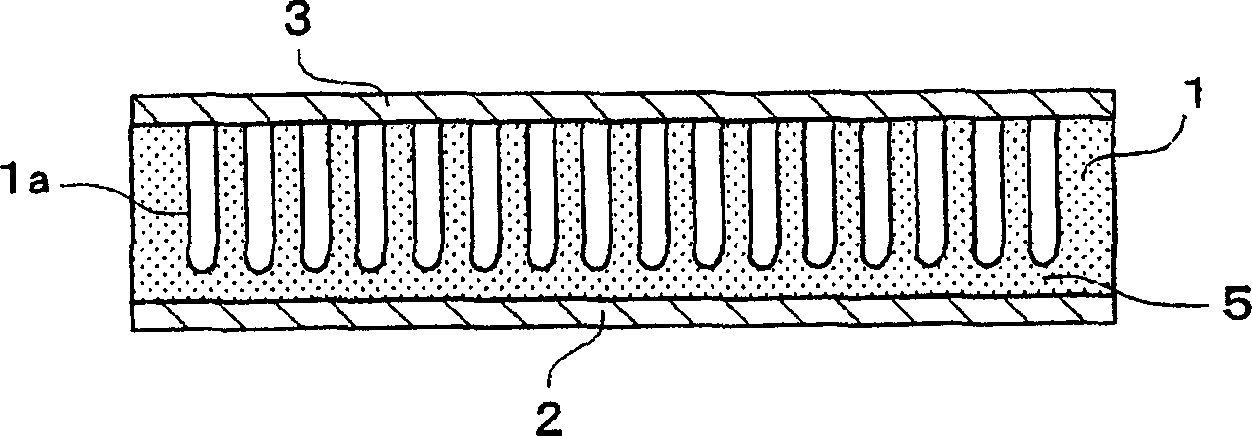

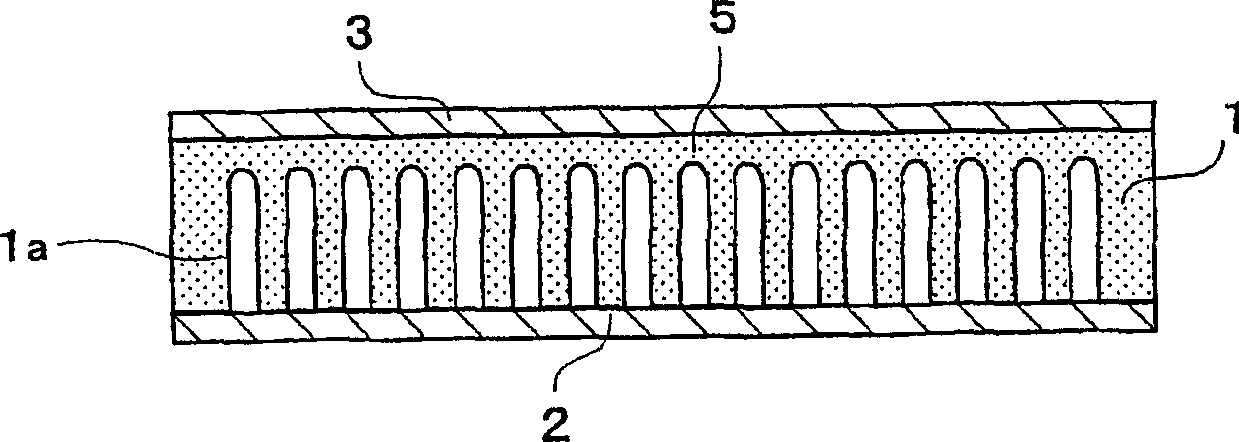

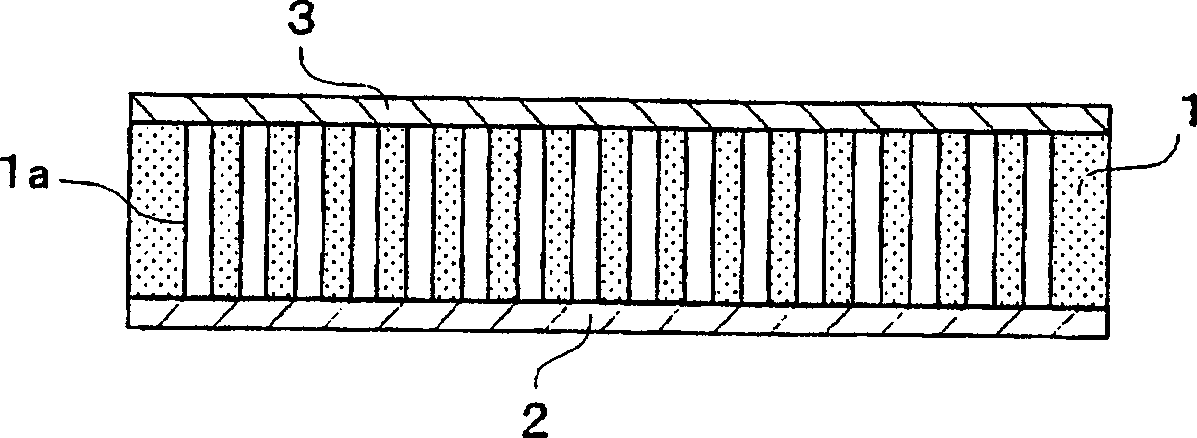

[0067] An Al substrate with a length of 50 mm x a width of 50 mm and a thickness of 2.5 mm was washed with methanol to remove oil, and then immersed in an electrolytic solution of phosphoric acid aqueous solution (phosphoric acid concentration: 4% by weight) kept at 20°C. Then, using the second Al plate as the counter electrode, as shown in Table 1, change the applied voltage (anodization voltage) and time (anodization time) for anodization to form a porous aluminum oxide layer (anodized layer) with nanopores. ). (Sample No.1~23)

[0068] In addition, after anodizing with the applied voltage of 65V, the barrier layer is dissolved by slowly lowering the anodizing voltage, so that the thickness of the barrier layer is less than 10nm, forming an anodic oxidation process in which nanopores penetrate the porous alumina layer substantially. Floor. (Sample No.24~29).

[0069] For the thus formed porous alumina layer having nanopores, the thickness of the nanopore-forming portion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com