Photoinduced thermoelectron emission source based on low work function composite nanomaterial and its preparation method

A technology of composite nanomaterials and electron emission sources, which is applied in the manufacture of thermionic cathodes, solid thermionic cathodes of discharge tubes, circuits, etc., can solve the problems of restricting photothermal electron emission performance, weak photothermal effect, and difficult photothermal electron emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

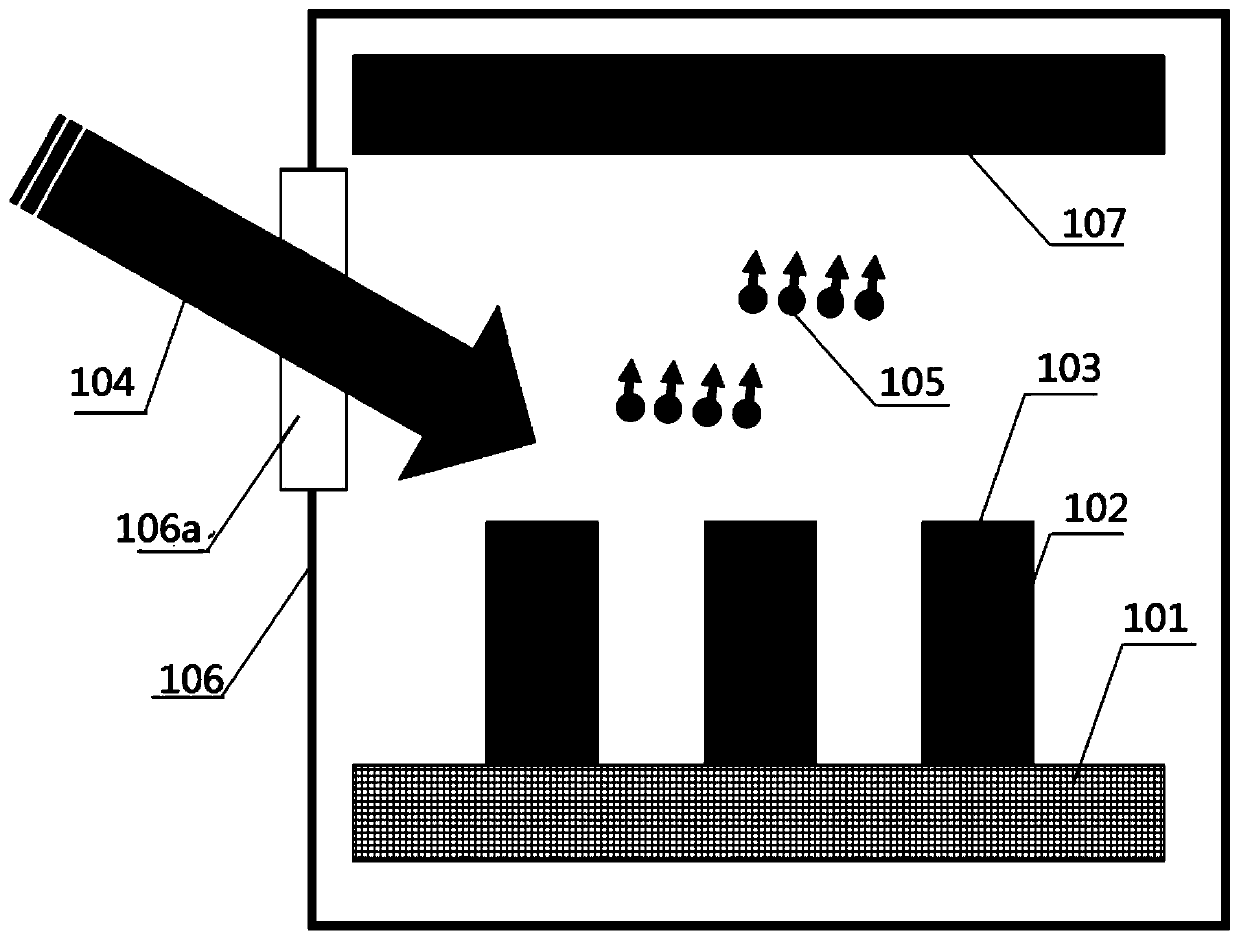

[0031] The present invention also provides a method for preparing a device based on a low work function composite nano material-based photothermal electron emission source electron emission source, which includes the following steps:

[0032] Step 1: Using a thermal vapor chemical deposition method to prepare a photothermal conversion material layer 102 on the cathode electrode 101;

[0033] Step 2: Depositing a low work function thermionic emission material film 103 on the surface of the prepared photothermal conversion material layer 102 by using an electron beam evaporation method;

[0034] The light-to-heat conversion material layer 102 adopts an array with optimized light absorption efficiency, and the distance between adjacent emitting units is 10 micrometers; in a preferred embodiment of the present invention, the light-to-heat conversion material layer 102 uses carbon nano A tube array. The carbon nanotube array is a cylindrical array with a height of 100 micrometers, a cylin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com