Concrete pipeline mud-jacking agent and preparation method

A grouting agent and concrete technology, which is applied in the field of building materials, can solve the problems of corrosion prestress loss of steel strands in pipes, small strength effect of grouting agent, and corrosion of cable wires, etc., and achieves good durability, firm bonding, High filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Concrete pipeline grouting agent comprises the following components in parts by weight:

[0016] Powdered modified polycarboxylate superplasticizer 1.5%

[0017] Bentonite 0.1%, polyacrylamide 0.1%, microsilica fume 0.1%

[0018] Alunite 1.5%, Calcined Kaolin 1.5%, Gypsum 1.5%

[0019] Anhydrous calcium sulfoaluminate 42%

[0020] Borax 0.2%, citric acid 0.3%

[0021] Infiltrate composite steel bar rust inhibitor 0.5%

[0022] Sodium alkylbenzene sulfonate 0.7%

[0023] Ultrafine slag powder 50%

[0024] The present invention is obtained by stirring and mixing each component according to the above weight percentage.

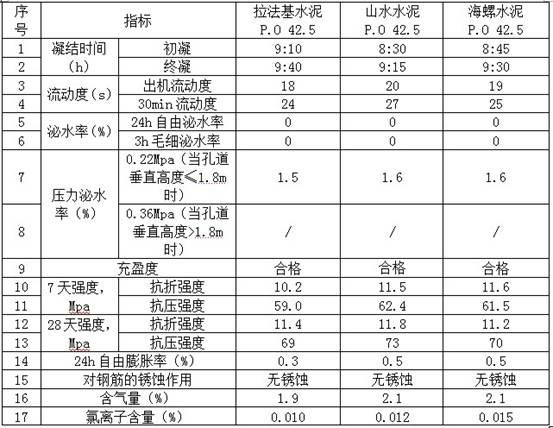

[0025] The properties of the grouting material formed by the present invention mixed with cement (replacing cement 15%) and water prepared according to the above formula are shown in Table 1.

[0026] The physical properties of the grout are shown in Table 1

[0027]

[0028] Note: The ratio of water to cement used is (that is, water / (cement + g...

Embodiment 2

[0030] Concrete pipeline grouting agent comprises the following components in parts by weight:

[0031] Powdered modified polycarboxylate superplasticizer: 2.0%

[0032] Polyacrylamide 0.2%, hydroxypropyl cellulose: 0.2%

[0033] Gypsum: 3.6%

[0034] Anhydrous calcium sulfoaluminate: 40%

[0035] Borax 0.4%

[0036] Infiltrate composite steel bar rust inhibitor 0.6%

[0037] Sodium alkylbenzene sulfonate 0.5%

[0038] Ultrafine slag powder 52.5%

[0039] The present invention is obtained by mixing and stirring each component according to the above weight percentage.

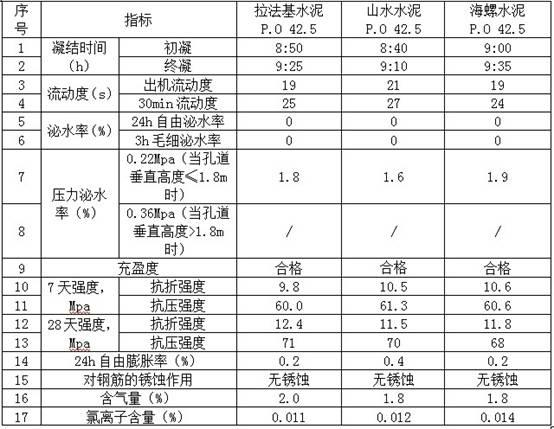

[0040] See Table 2 for the performance of the grouting material formed by the present invention mixed with cement (replacing cement 15%) and water according to the above formula.

[0041] The physical properties of the grout are shown in Table 2

[0042]

[0043] Note: The ratio of water to cement used is (that is, water / (cement + grouting agent) is 0.32), the dosage of the present invention is intern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com