Production process of high-quality fatty alcohol polyoxyethylene ether sulfate

An alcohol polyoxyethylene ether and production process technology, applied in the preparation of sulfate, organic chemistry and other directions, can solve the problems of high AEO content, unstable sulfonation reaction, product decomposition, etc., and achieve good color and luster, stable sulfonation process, Stabilizing effect of sulfonation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Pre-add 0.1% stearic acid by mass in AEO and dissolve in advance.

[0023] (2) AEO that is dissolved with stearic acid, according to the sulfonation production process of existing fatty alcohol polyoxyethylene ether sulfate, in existing gas phase SO 3 Sulfonation is carried out on a membrane sulfonation device;

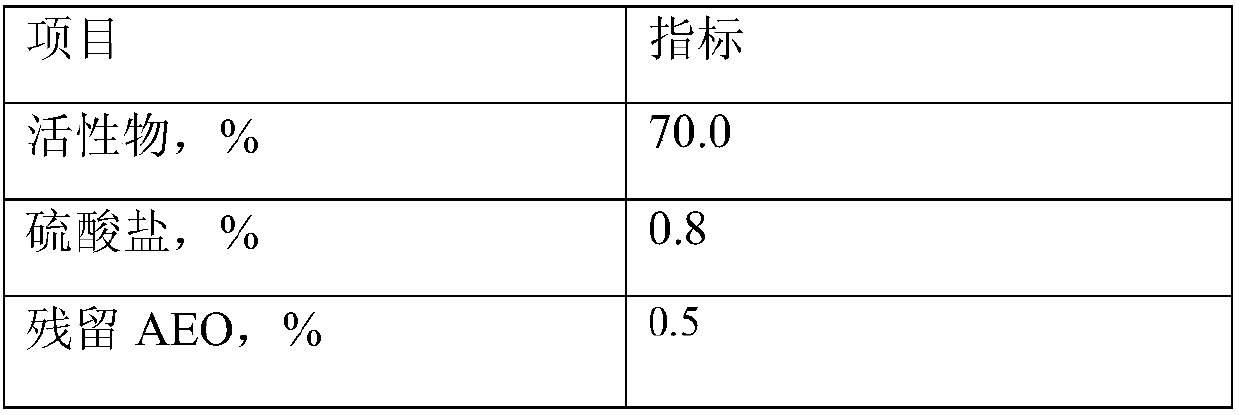

[0024] (3) After sulfonation, the ester directly enters the vacuum neutralization system without aging, and produces fatty alcohol polyoxyethylene ether sodium sulfate according to the existing neutralization process. The obtained product quality index is as follows

[0025]

[0026]

Embodiment 2

[0028] (1) Pre-add 0.2% lauric acid in total mass to AEO and dissolve in advance.

[0029] (2) AEO that is dissolved with lauric acid, according to the sulfonation production process of existing fatty alcohol polyoxyethylene ether sulfate, in existing gas phase SO 3 Sulfonation is carried out on a membrane sulfonation device;

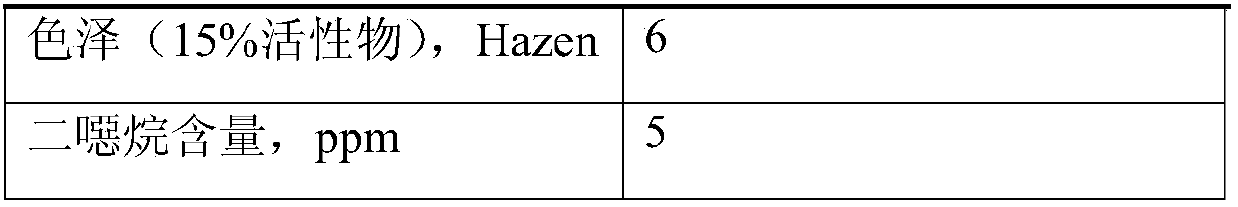

[0030] (3) After sulfonation, the ester directly enters the vacuum neutralization system without aging, and produces fatty alcohol polyoxyethylene ether sodium sulfate according to the existing neutralization process. The obtained product quality index is as follows

[0031] project

Embodiment 3

[0033] (1) Add 0.3% of total mass of methyl laurate into AEO in advance and dissolve in advance.

[0034] (2) AEO that is dissolved with methyl laurate, according to the sulfonation production process of the existing fatty alcohol polyoxyethylene ether sulfate, in the existing gas phase SO 3 Sulfonation is carried out on a membrane sulfonation device;

[0035] (3) The acid ester after sulfonation does not need to be aged, and directly enters the vacuum neutralization system to produce fatty alcohol polyoxyethylene ether sodium sulfate according to the existing neutralization process. The obtained product quality index is as follows

[0036] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com