Oat dairy product and preparation method thereof

A technology for dairy products and oats, which is applied to the field of oat dairy products and their preparation, can solve the problems that oat milk particles are prone to aging and retrograde, cannot retain the elastic taste of large oat particles, and the stability of oat milk products is not good, and achieves no problem. The effect of aging and rejuvenation of oat granules, good taste and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

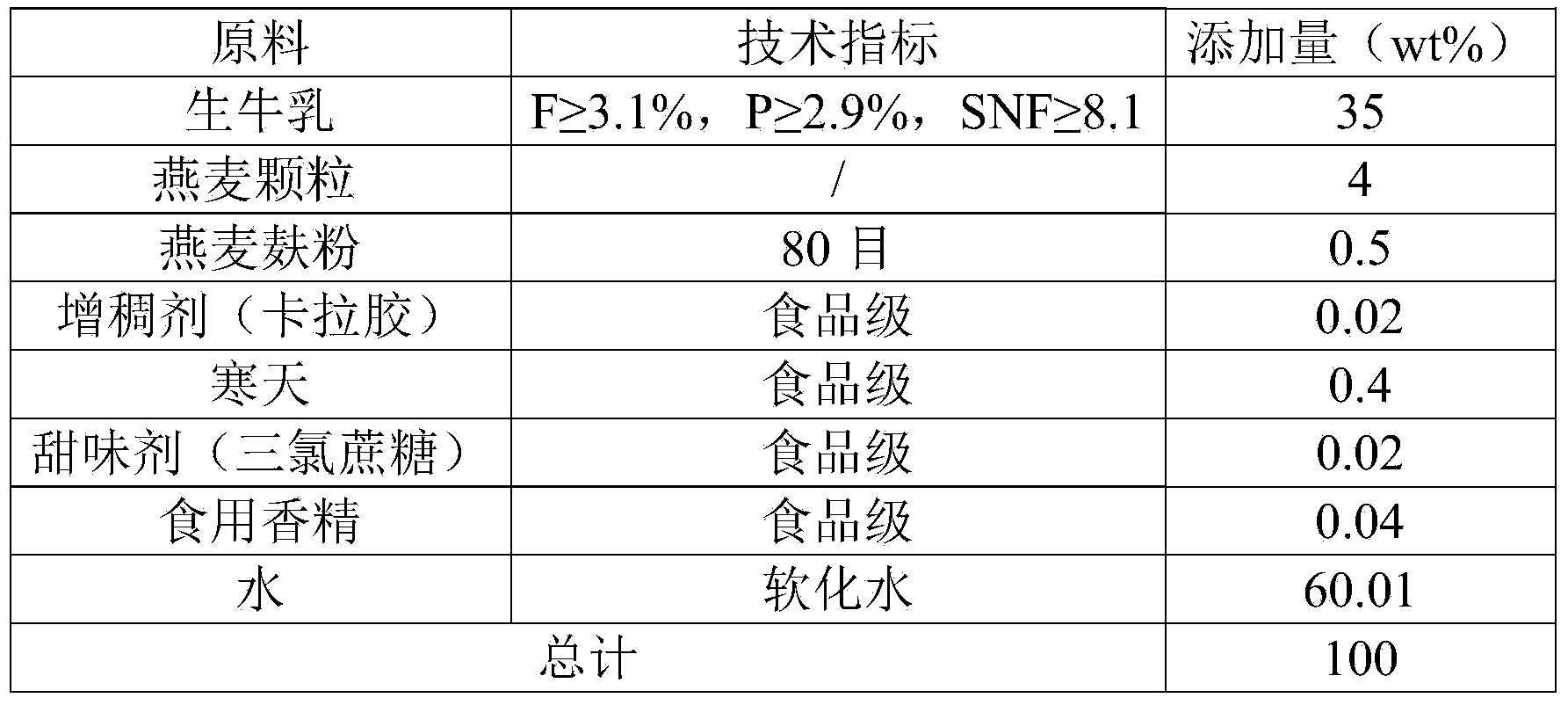

[0052] 1. Raw material formula (see Table 1).

[0053] The raw material formula of table 1 embodiment 1

[0054]

[0055] 2. Preparation method:

[0056] ① Boil peeled oat granules in boiling water for 20 minutes, then add oat bran powder, keep stirring at 80°C for 5 minutes, and obtain feed liquid A;

[0057] ② Stir raw milk, cold weather, thickener, sweetener and water at 75°C for 10 minutes and mix evenly to obtain material liquid B;

[0058] ③After testing (GB-5009.5), the fat content in the feed liquid B is 1.085%, and the feed liquid B is subjected to primary homogenization, wherein the primary homogenization pressure is 20MPa, and the homogenization temperature is 65°C , the percentage is the mass percentage relative to the mass of the feed liquid B;

[0059] ④ Stir the homogenized feed liquid B, feed liquid A and food flavor together at 60°C for 10 minutes, and mix well;

[0060] ⑤ Perform immersion ultra-high temperature instantaneous (also known as Infusion UH...

Embodiment 2

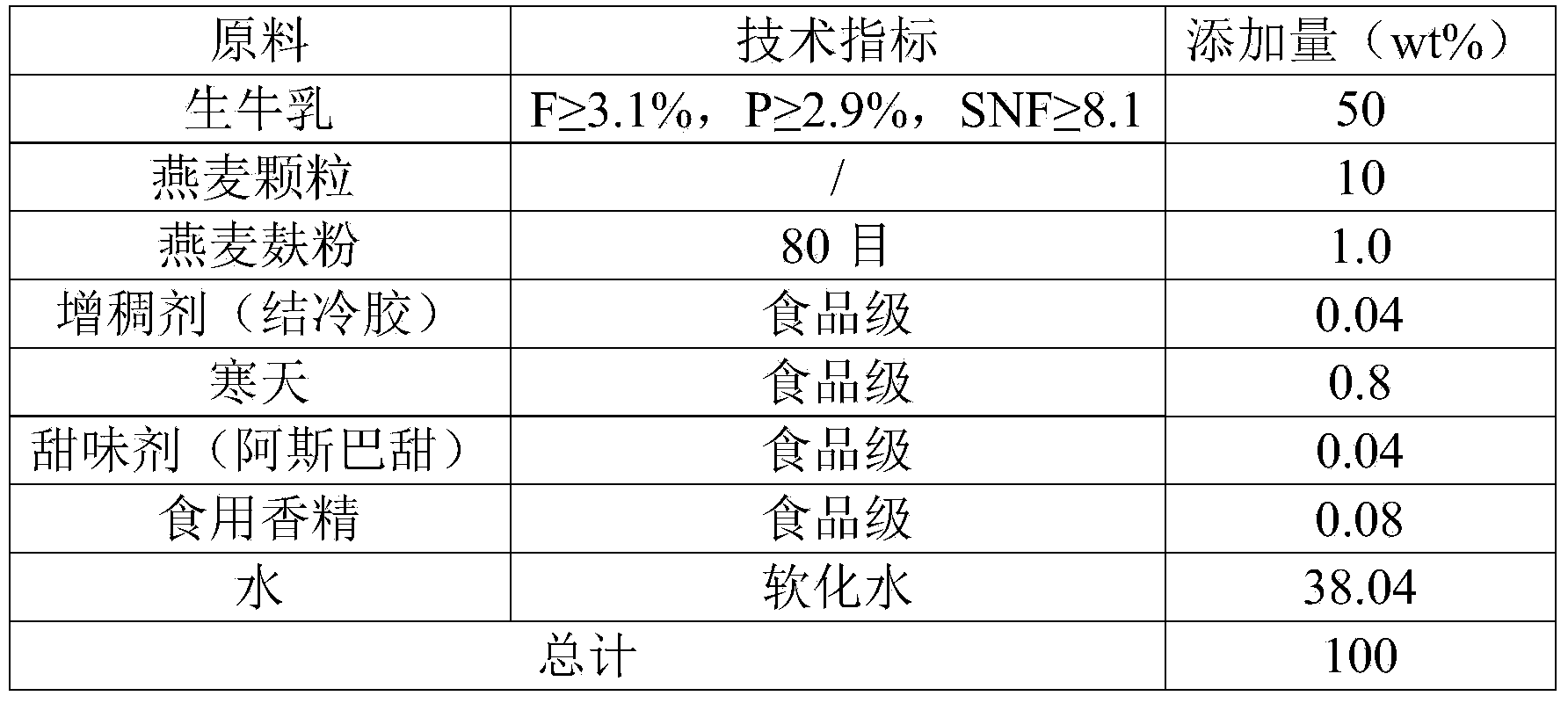

[0064] 1. Raw material formula (see Table 2).

[0065] The raw material formula of table 2 embodiment 2

[0066]

[0067] 2. Preparation method:

[0068] ① Boil peeled oat granules in boiling water for 30 minutes, then add oat bran powder, keep stirring at 83°C for 10 minutes, and obtain feed liquid A;

[0069] ② Stir the raw milk, cold weather, thickener, sweetener and water at 78°C for 15 minutes, and mix well to obtain material liquid B;

[0070] ③ The fat content in the feed liquid B is 1.55%, and the feed liquid B is subjected to secondary homogenization, wherein the primary homogenization pressure is 20MPa, the secondary homogenization pressure is 5MPa, and the homogenization temperature is 65-70°C; The percentage is the mass percentage relative to the mass of the feed liquid B;

[0071] ④ Stir the homogenized feed liquid B, feed liquid A and food flavor together at 65°C for 12 minutes, and mix well;

[0072] ⑤ Perform immersion ultra-high temperature transient (a...

Embodiment 3

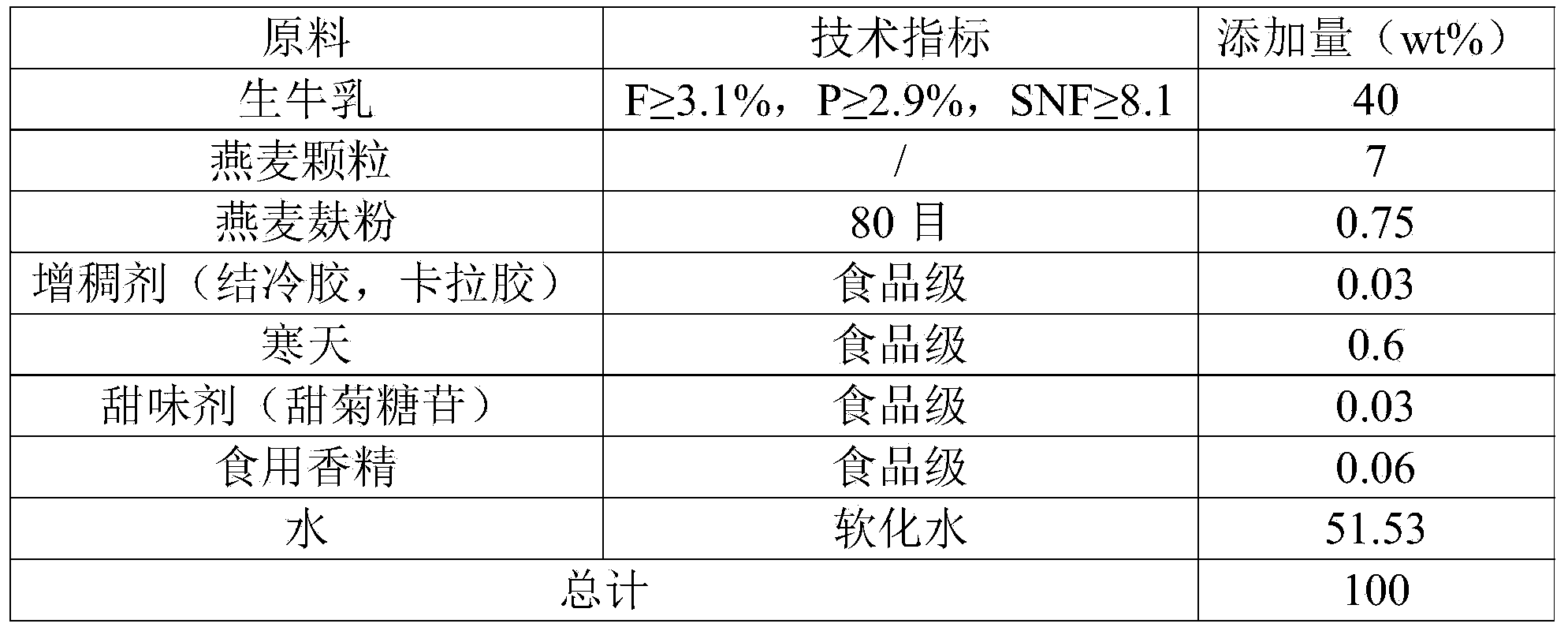

[0076] 1. Raw material formula (see Table 3). In the thickener, the mass ratio of gellan gum and carrageenan is 4:1.

[0077] The raw material formula of table 3 embodiment 3

[0078]

[0079] 2. Preparation method:

[0080] ① Boil peeled oat granules in boiling water for 25 minutes, then add oat bran powder, keep stirring at 85°C for 8 minutes, and obtain feed liquid A;

[0081] ② Stir the raw milk, cold weather, thickener, sweetener and water at 80°C for 15 minutes, and mix well to obtain material liquid B;

[0082] ③The fat content in the feed liquid B is 1.24%, and the feed liquid B is subjected to primary homogenization, wherein the homogenization pressure is 20MPa, and the homogenization temperature is 65°C; the percentages are relative to the feed liquid B. The mass percentage of liquid B quality;

[0083] ④ Stir the homogenized feed liquid B, feed liquid A and food flavor together at 70°C for 12 minutes, and mix well;

[0084] ⑤ Perform immersion ultra-high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com