Combustion control system and control method for power plant

A control method and technology for a control system, which are applied in the power plant combustion control system and control field, and can solve problems such as poor versatility, negative effect of error integral feedback, and PID controller control quantity error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Taking a 600MW coal-fired power plant in China as an example, the goal of this embodiment is to make the temperature in the furnace evenly distributed, and the specific process of the present invention will be described in detail next.

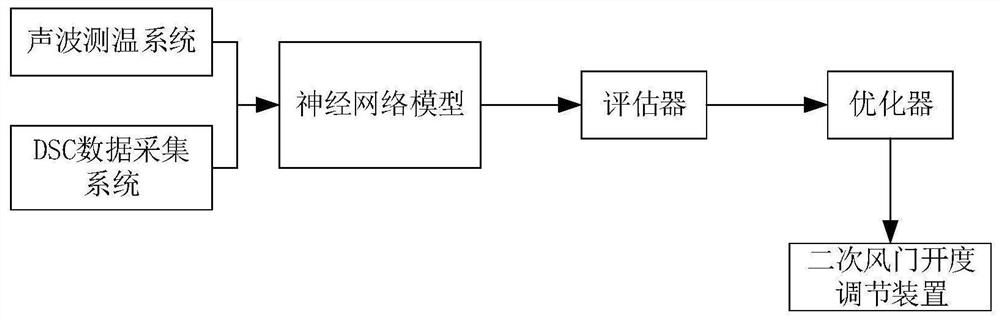

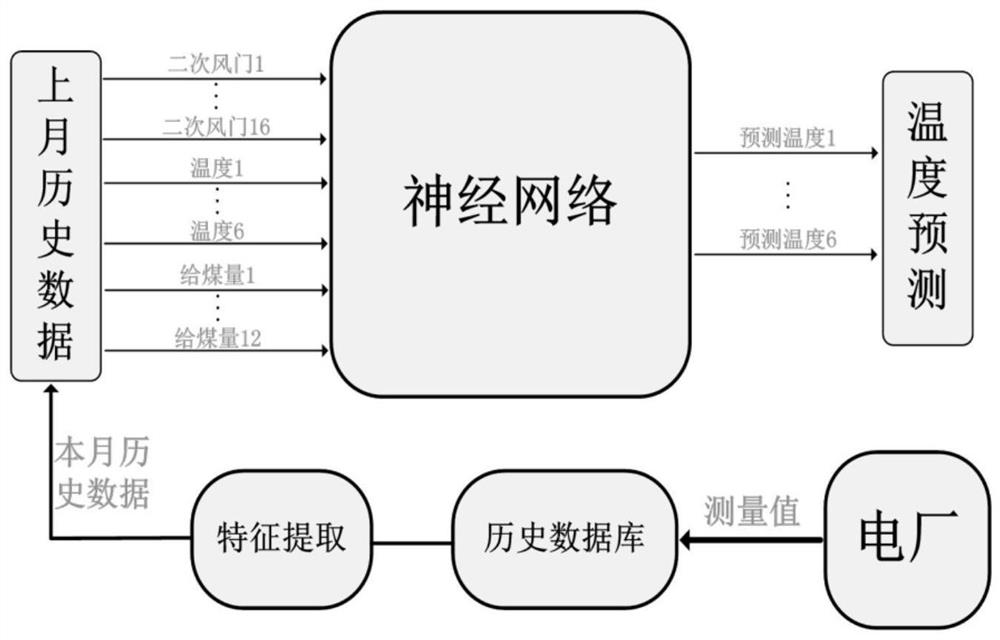

[0059] The establishment of neural network models, such as figure 2 and image 3 As shown in the figure, firstly find the key data from the historical database of the power plant last month, take the opening of the secondary air door and the amount of coal feeding as the input, and the temperature distribution in the furnace as the output to establish a neural network model.

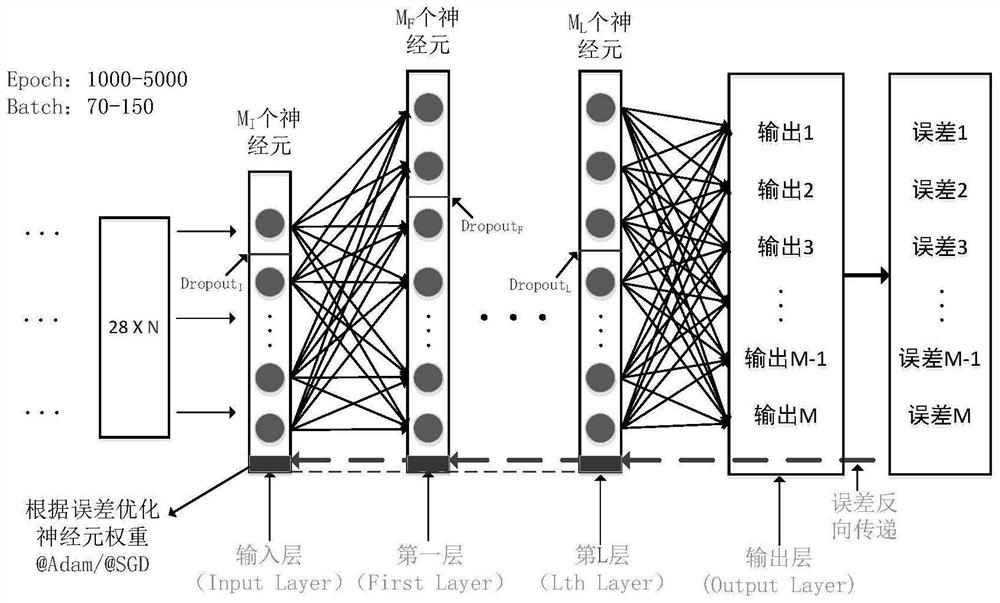

[0060] In this embodiment, the input is a 28×N matrix, wherein the 28 data in each column are 16 secondary air valve opening values and 12 coal feeding amount values respectively. The number of input matrix columns represents the time depth, where the time depth is set as the parameter N; the output is a 6X1 vector, representing the predicted temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com