Predischarge lightning conductor

A pre-discharge and lightning rod technology, applied in corona discharge devices, circuits, collectors, etc., can solve the problems of no early discharge, high-voltage substation lightning tripping, etc., to reduce secondary effects, low load requirements, and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

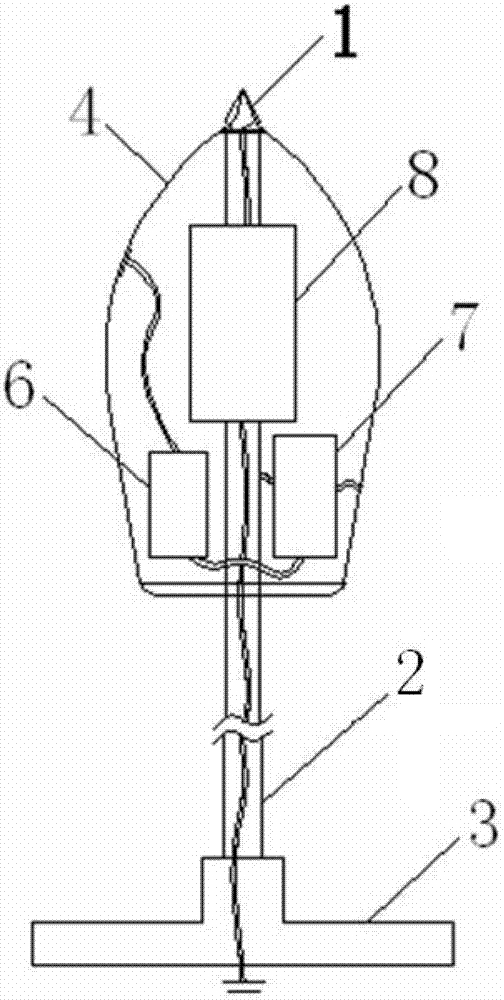

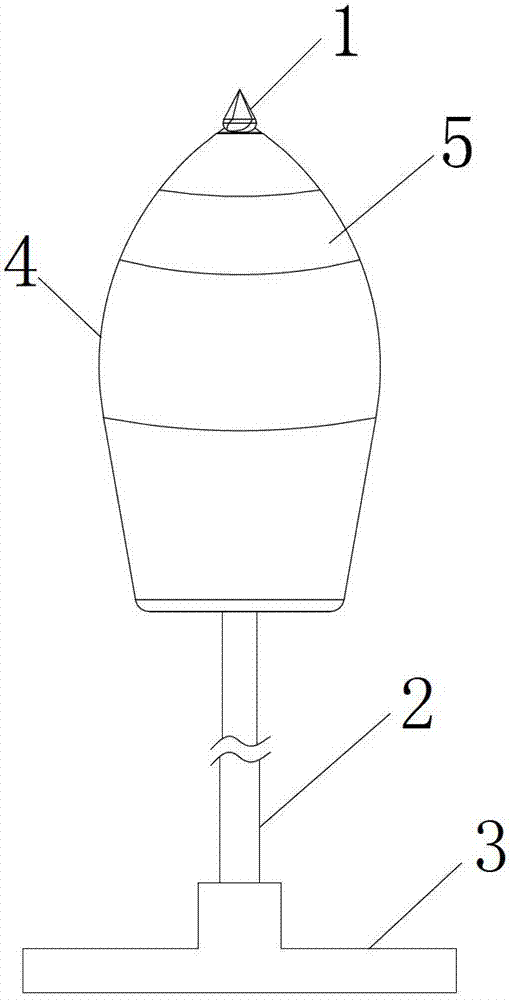

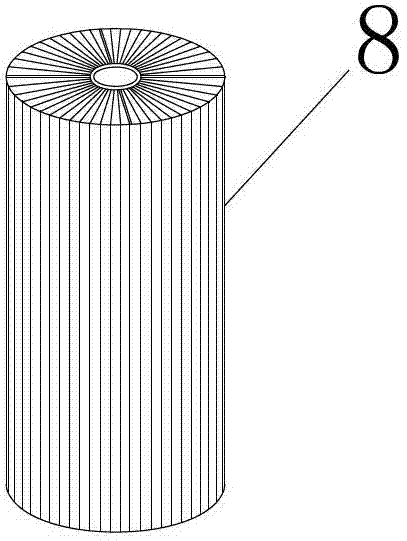

[0022] as attached figure 1 And attached figure 2 As shown, the present invention includes an air-termination body 1, a down conductor, a support rod 2 and a base 3, the air-termination body 1 is made of a metal material, the air-termination body 1 is a cone, and the air-termination body 1 is fixedly connected to one end of the down-conductor, the other end of the down-conductor is connected to the base 3, and the base 3 is connected to the ground, the down-conductor is arranged in the support rod 2, and the upper part of the support rod 2 Needle cover 4 is provided, and described needle cover 4 is made of insulating material, and described needle cover 4 is a hollow ellipsoid, and the outer surface of described needle cover 4 is equipped with solar energy absorbing plate 5, and described needle cover 4 is provided with The storage battery 6 and the pre-disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com