Float-type wave vibration generating device for magnetostriction slice

A technology of vibration power generation and magnetostriction, which is applied in the direction of piezoelectric effect/electrostriction or magnetostriction motor, ocean energy power generation, generator/motor, etc., to achieve high energy conversion efficiency and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

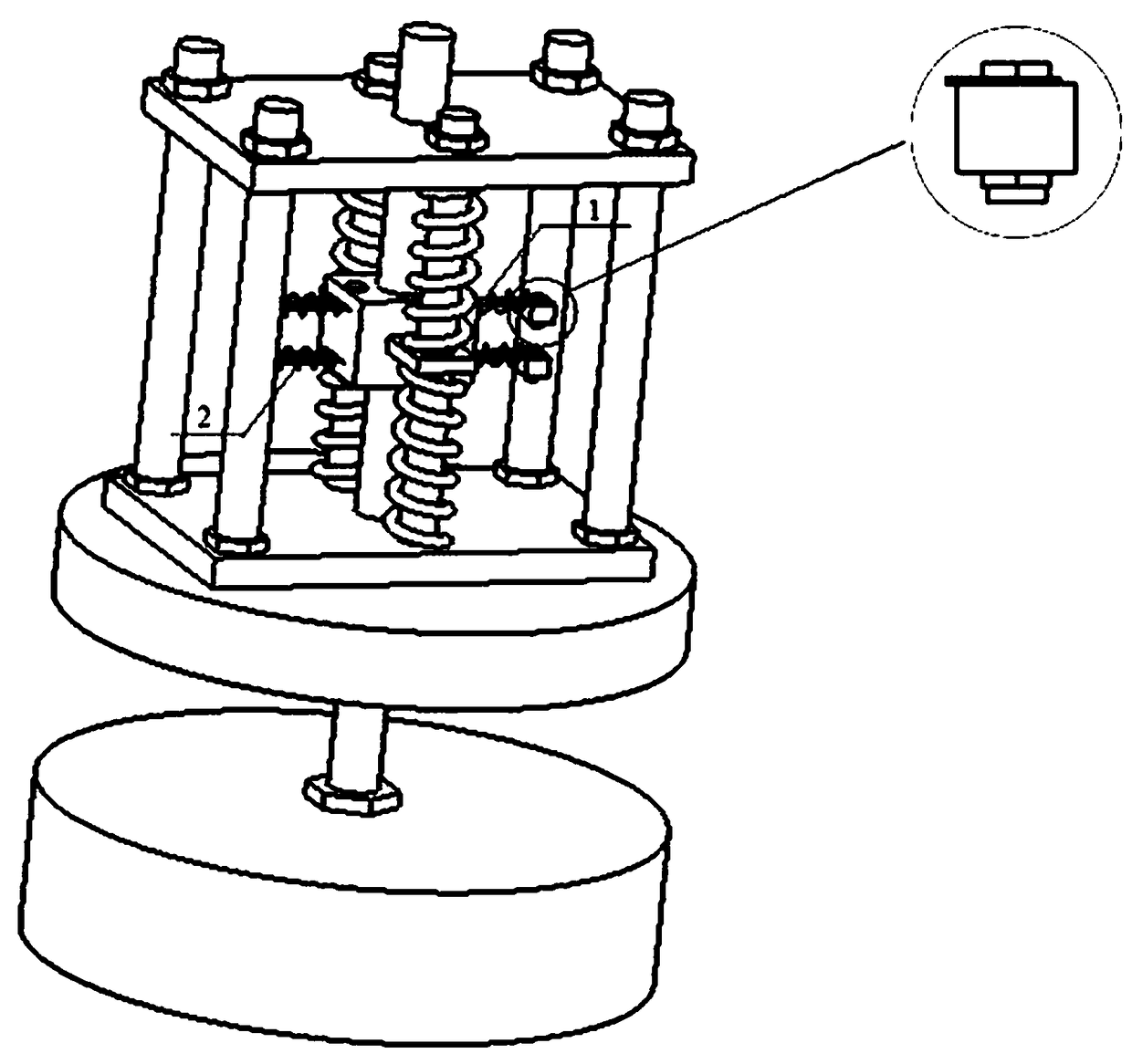

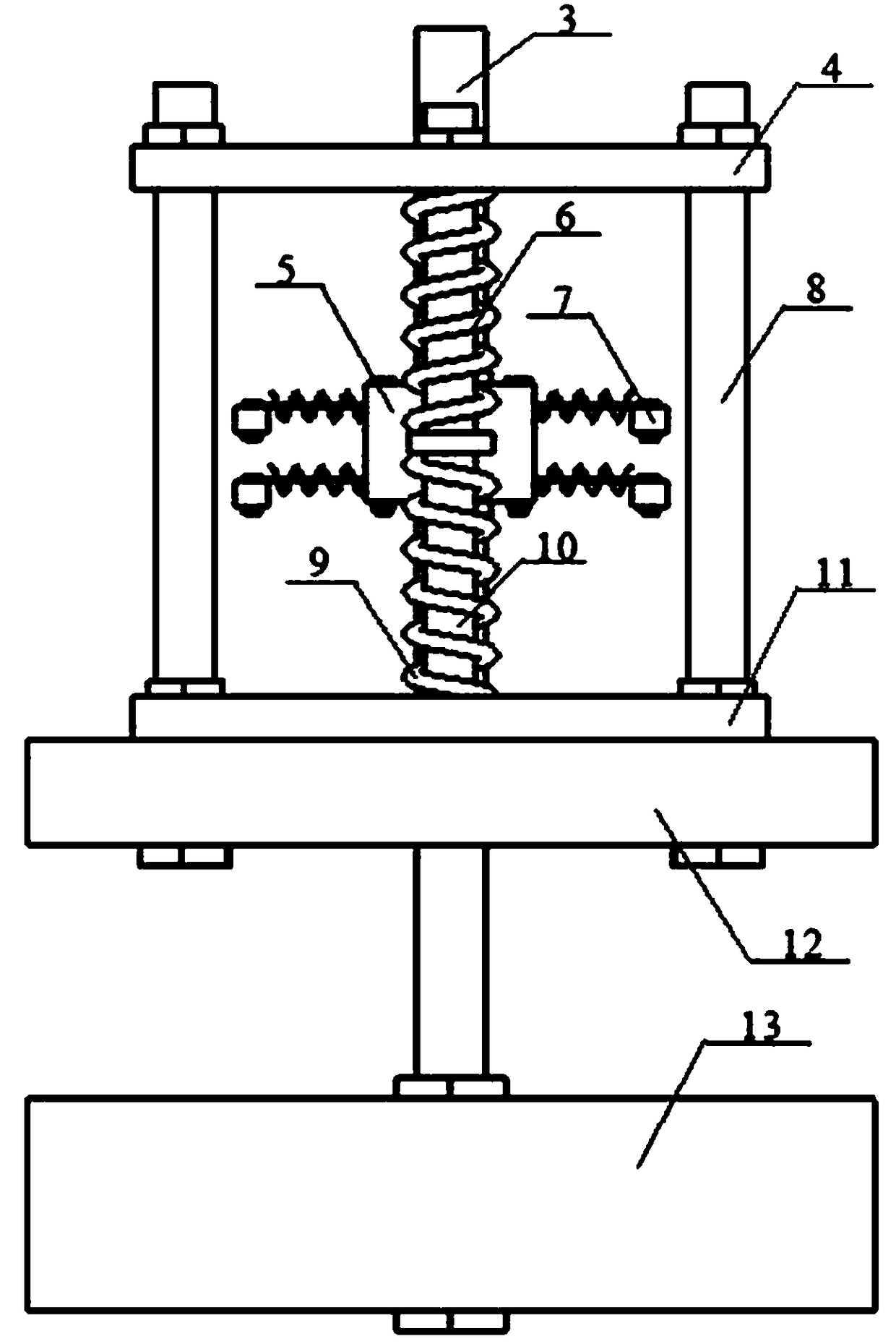

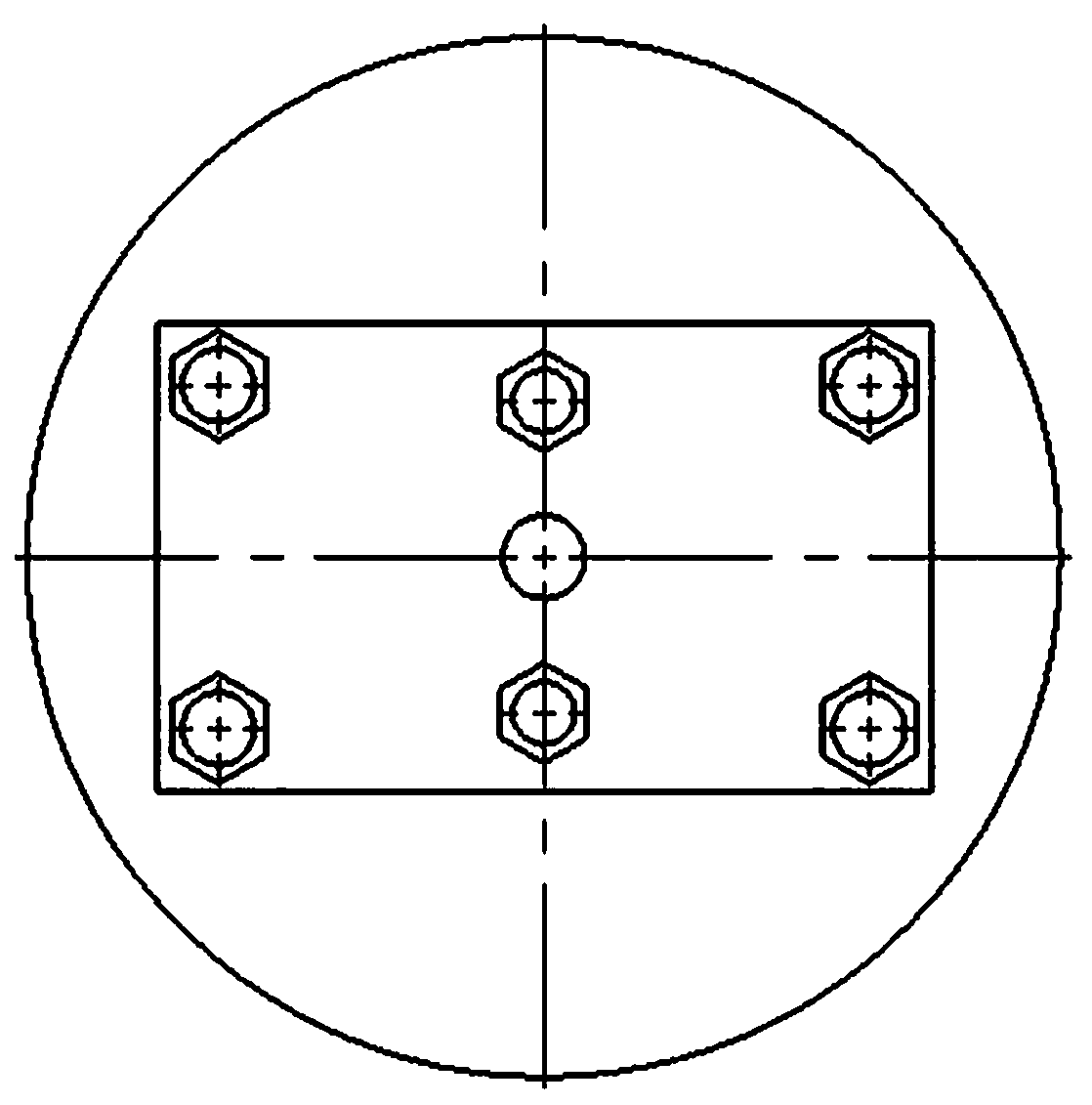

[0040] Below in conjunction with accompanying drawing, the present invention will be further described:

[0041] The magnetostrictive sheet float type wave vibration power generation device of the present invention takes the giant magnetostrictive sheet as the core component, drives the fixed block to swing up and down through the transmission shaft to provide vibration for the giant magnetostrictive sheet, and adopts the pickup coil to convert the change of magnetic flux As the voltage, the process of converting the vibration energy in the wave undulating motion into electrical energy output is realized. The working principle of the device of the present invention is: when the floating body swings up and down under the action of waves, the transmission shaft will move, and the fixed block will be driven to move up and down, and the giant magnetostrictive sheet will also vibrate at the same time. Inverse effect (Villari effect), the vibration will cause the magnetization state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com