A production method of an aluminum profile frame for a high-speed rail sound barrier

A production method and aluminum profile technology, applied in the field of aluminum profile manufacturing, can solve problems such as short service life, fading, and easy aging of aluminum profile frame component materials, and achieve the effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

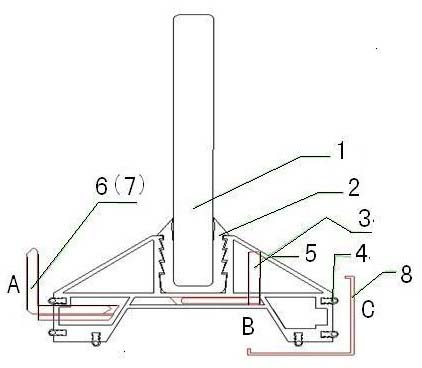

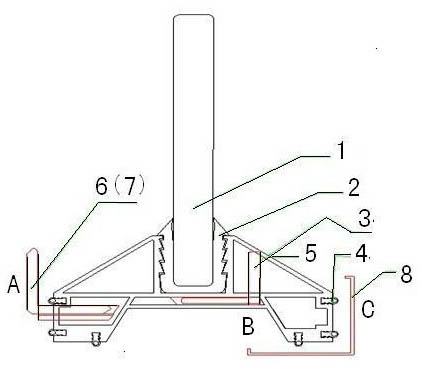

[0016] A production method of an aluminum profile frame for a high-speed rail sound barrier uses aluminum rods as the main material, and undergoes mold design, batching, smelting, extrusion, discharging, artificial aging, powder spraying, and assembly molding. Aluminum profile frame, the frame is surrounded by aluminum alloy frame 3, sawed and cut into 45° angle, A is connected with corner code 6; Yuan ethylene propylene rubber 4; C place outer frame is connected with spring leaf 8, to increase strength.

[0017] The production method of the aluminum alloy frame comprises the following steps:

[0018] 1. Mold design: The mold size is 280*185, such a large size can increase the strength of the mold, and it is not easy to collapse; the design uses 7 diversion holes, 6 bridge positions, and a double hole in the middle, which can serve as an intermediate supply Foot, the foreman is not easy to shift and so on. The depth of the welding chamber is 25, which plays the role of weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com