Solar battery

A solar cell and electrode technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of non-deformable substrates, low light energy conversion efficiency, thick substrates, etc., and achieve low internal resistance, high photoelectric conversion efficiency, and reliability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

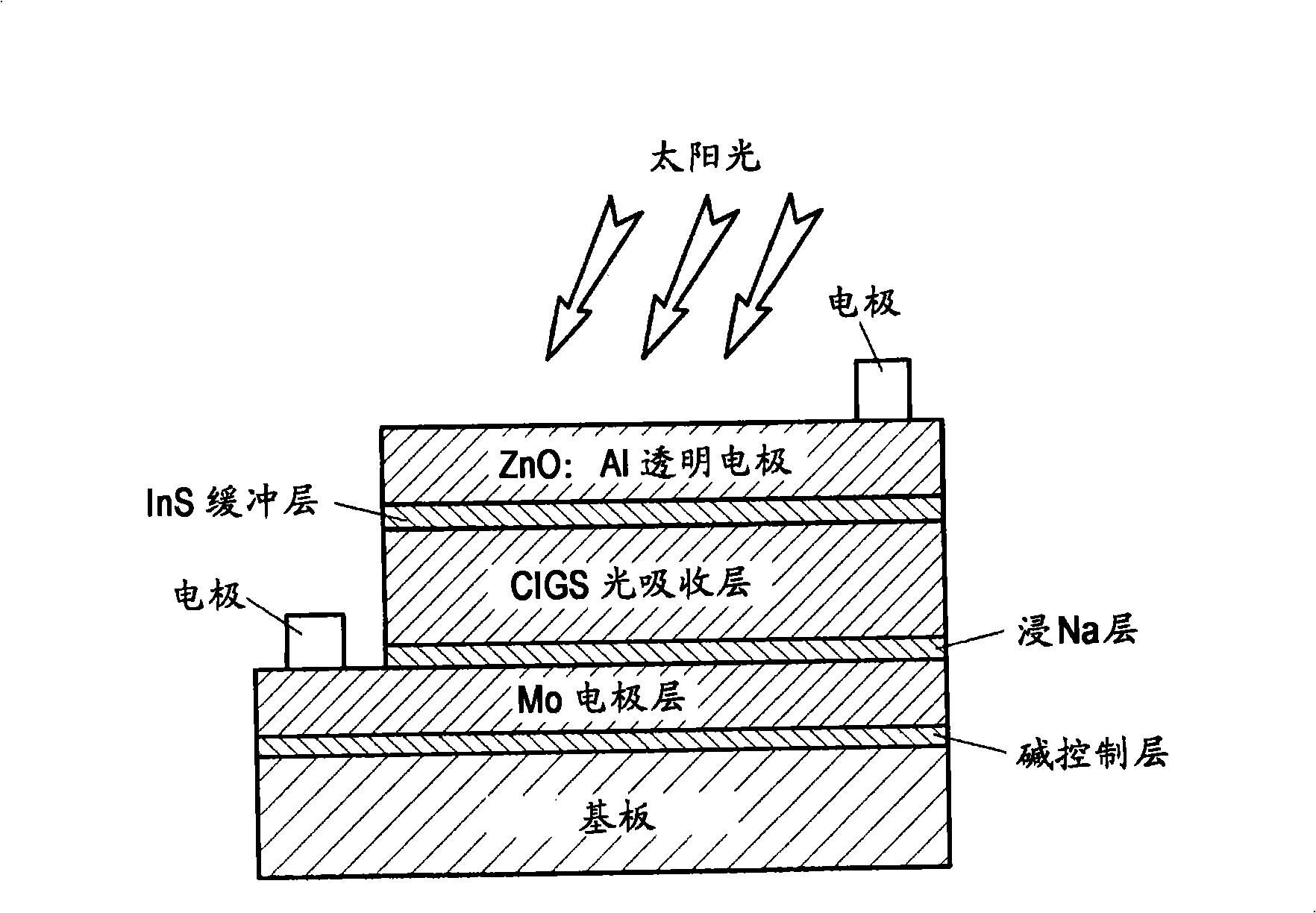

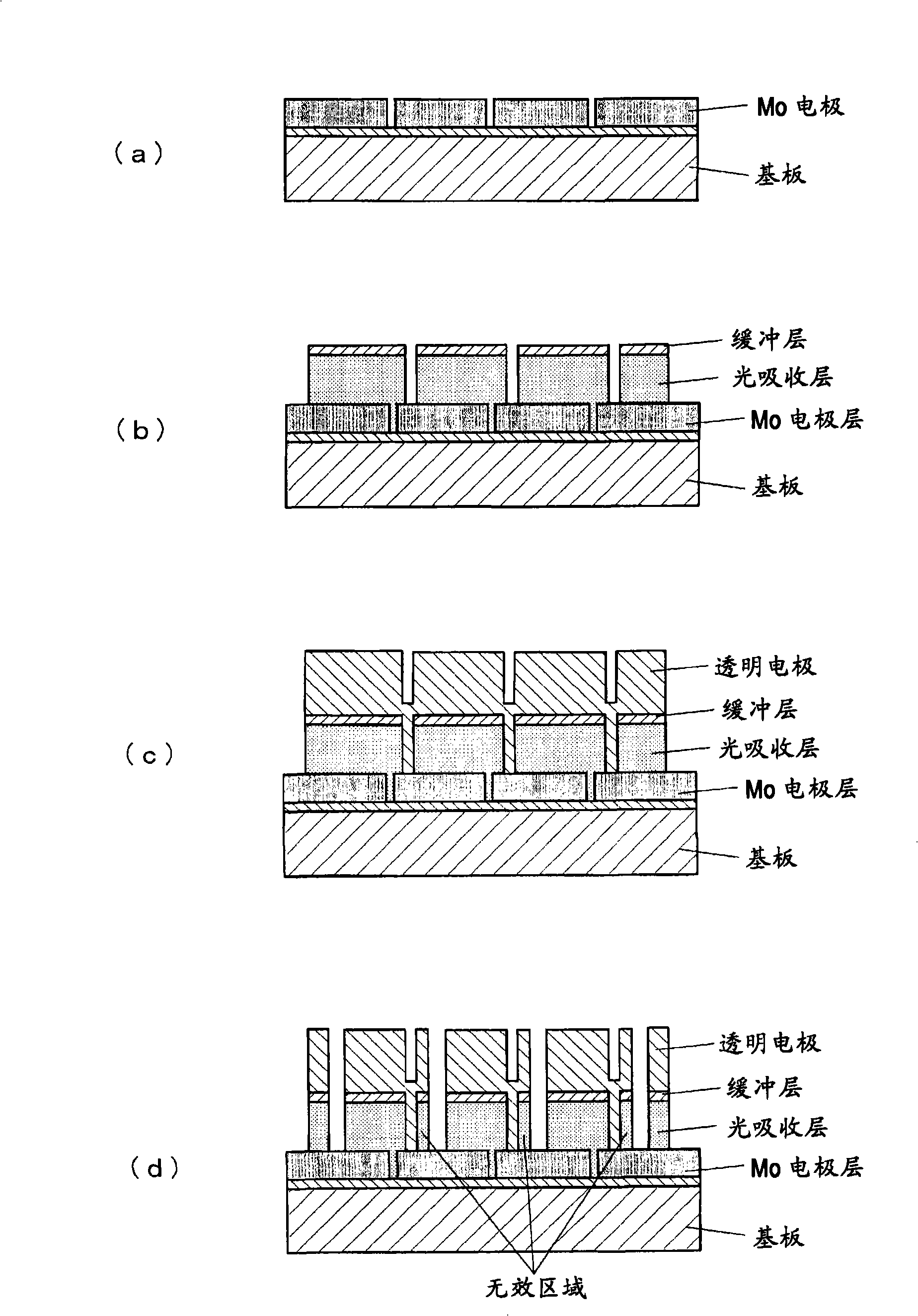

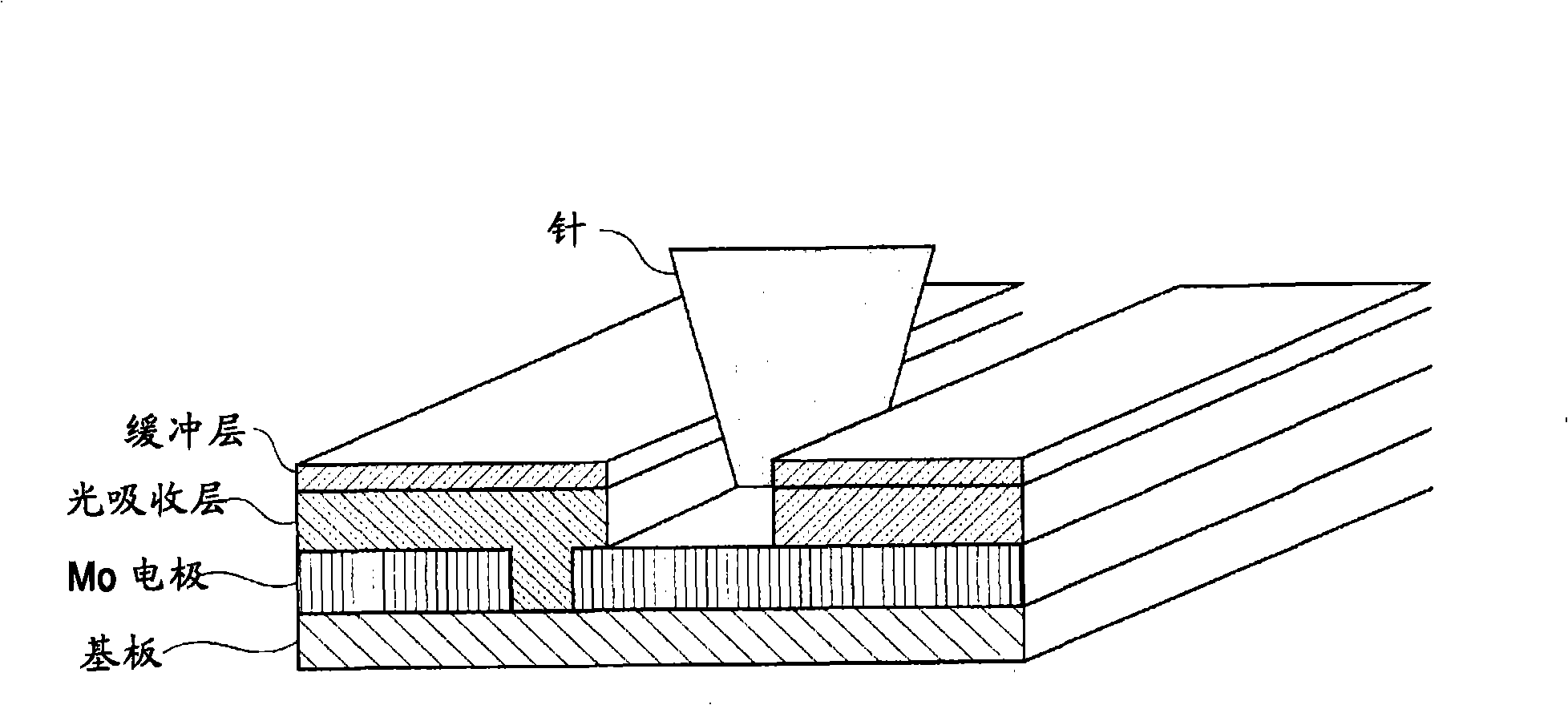

[0046] Figure 5 The chalcopyrite solar cell of the present invention is shown. here, Figure 5 (a) is a cross-sectional view of a main part of a solar cell (battery cell), and (b) is an exploded view illustrating a unit cell constituting a solar cell (battery cell).

[0047] The solar cell is formed with a battery cell 10 (unit battery cell) composed of a lower electrode layer 2 (Mo electrode layer) formed on a flexible substrate 1 (substrate: base layer), containing copper, indium, gallium, and selenium The light absorbing layer 3 (CIGS light absorbing layer), the high resistance buffer layer film 4 formed by InS, ZnS, CdS, etc. on the light absorbing layer 3, and the upper electrode layer 5 (TCO) formed by ZnOAl etc. form a unit, In addition, in order to connect a plurality of unit cells 10 in series, a contact electrode portion 6 that connects the upper electrode layer 5 and the lower electrode layer 2 is formed.

[0048] In this contact electrode portion 6, the ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com