Anti-retrogradation germinated brown rice cake and production method thereof

A technology of germinated brown rice and its production method, which is applied in the field of food processing, can solve problems such as insufficient effects, and achieve the effects of uniform and delicate tissue structure, reduced retrogradation, and rich rice flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

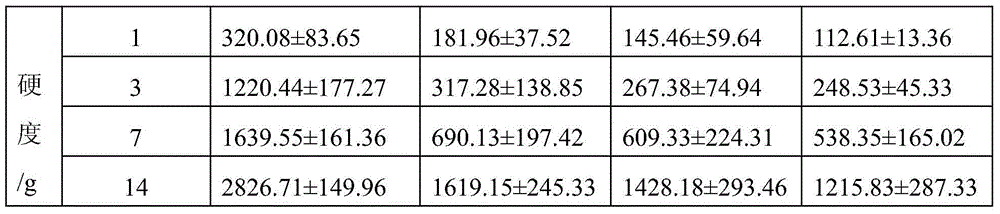

Embodiment 1

[0019] The brown rice obtained after paddy husking is sieved, and impurities are removed to select plump and intact brown rice grains, soaked in deionized water for 30 minutes and rinsed. Then spread the brown rice on a petri dish, add deionized water, put it into a constant temperature incubator at 28°C to germinate for 60 hours, change the water every 6 hours, then pass the prepared fresh wet germinated brown rice through a colloid mill, and press Filter, dry, crush, and pass through a 100-mesh sieve. With 70 parts of glutinous rice flour and 3% (in terms of total rice flour weight, the same below; wherein the weight of total rice flour is the sum of the weight of glutinous rice flour and the weight of germinated brown rice flour) oxidized hydroxypropyl starch, 3% gluten Flour, 5% vegetable oil and 0.5% monoglyceride are thoroughly mixed, then 8% white sugar is added to 54% water to dissolve completely, and then the sugar water is slowly added to the glutinous rice flour, wr...

Embodiment 2

[0021] The brown rice obtained after paddy husking is sieved, and impurities are removed to select plump and intact brown rice grains, soaked in deionized water for 30 minutes and rinsed. Then spread the brown rice on a petri dish, add deionized water, put it into a constant temperature incubator at 28° C. to germinate for 72 hours, and change the water every 6 hours. The germinated brown rice with an average bud length of 6-7mm is obtained, and then the prepared fresh wet germinated brown rice is pulverized through a colloid mill, filtered, dried, pulverized, and passed through a 100-mesh sieve. With the oxidized hydroxypropyl starch of 60 parts of glutinous rice flour and 2.5% (in terms of total rice flour weight, the same below; wherein the weight of total rice flour is the weight of glutinous rice flour and the weight of germinated brown rice flour), 2.5% gluten Flour, 4% vegetable oil and 0.4% monoglyceride are fully mixed, then 7% white sugar is added to 52% water to dis...

Embodiment 3

[0023] The brown rice obtained after paddy husking is sieved, and impurities are removed to select plump and intact brown rice grains, soaked in deionized water for 30 minutes and rinsed. Then spread the brown rice on a petri dish, add deionized water, put it into a constant temperature incubator at 30°C to germinate for 60 hours, and change the water every 6 hours. Then the prepared fresh wet germinated brown rice is passed through a colloid mill to be pulverized, press-filtered, dried, pulverized, and passed through a 100-mesh sieve. With 50 parts of glutinous rice flour and 2% (in terms of total rice flour weight, the same below; wherein the weight of total rice flour is the sum of the weight of glutinous rice flour and the weight of germinated brown rice flour) oxidized hydroxypropyl starch, 2% gluten Flour, 4% vegetable oil and 0.3% monoglyceride are fully mixed, then 7% white sugar is added to 50% water to dissolve completely, and then the sugar water is slowly added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com