Prebaked anode and preparation method and application thereof

A prebaked anode and roasting technology, which is applied in the field of electrolysis, can solve the problems of prebaked anode being easily oxidized and insufficient mechanical strength, and achieve the effect of increasing the residual electrode rate and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

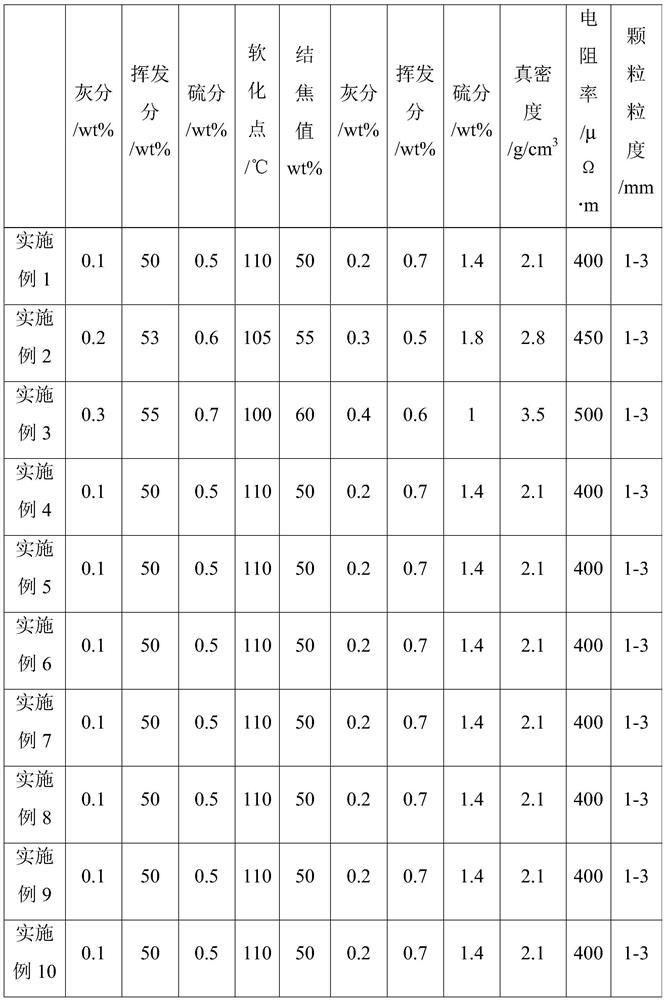

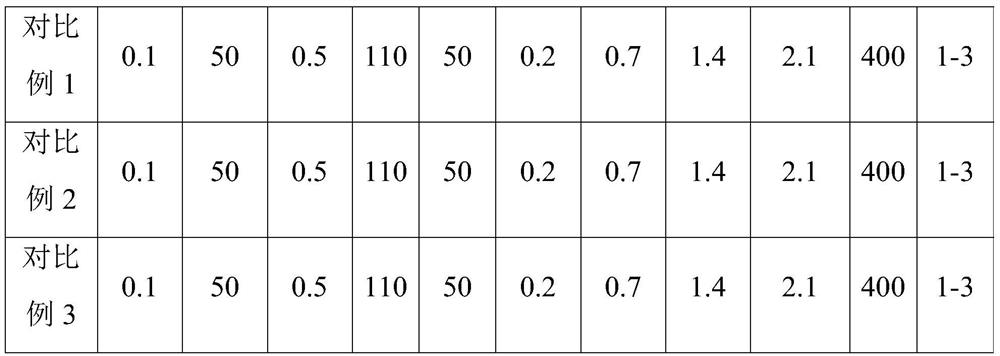

Embodiment 1

[0043] (1) Modify the asphalt according to the ratio in Table 2, the modification temperature is 175°C, shear 20min at a speed of 2955r / min, and stir for 2h to obtain modified asphalt;

[0044] (2) Crush the petroleum coke to a particle size of 1-3mm, mix the crushed petroleum coke and modified pitch at a weight ratio of 8:1, and then put the mixed raw materials into an electric kneader with a kneading temperature of 120°C. Vibrate for 5 minutes;

[0045] (3) The kneaded material is roasted in a tunnel kiln, and the temperature is raised from an initial temperature of 20 °C to 1100 °C at a rate of 0.5 °C / min, and the prebaked electrode is obtained after heat preservation and roasting for 80 hours.

Embodiment 2

[0047] (1) Modify the asphalt according to the ratio in Table 2, the modification temperature is 165°C, the shearing time is 15min at 2955r / min, and the mixture is stirred for 3h to obtain the modified asphalt;

[0048](2) Crush the petroleum coke to a particle size of 1-3 mm, mix the crushed petroleum coke and modified pitch at a weight ratio of 12:1, and then put the mixed raw materials into an electric kneader at a kneading temperature of 150°C. Vibrate for 8 minutes;

[0049] (3) The kneaded material is roasted in a tunnel kiln, the initial temperature is raised from 20 °C to 1150 °C at 1 °C / min, and the prebaked electrode is obtained after heat preservation and roasting for 90 hours.

Embodiment 3

[0051] (1) Modify the asphalt according to the ratio in Table 2, the modification temperature is 180°C, shear 18min at 2968r / min, stir for 4h, and obtain modified asphalt;

[0052] (2) Crush the petroleum coke to a particle size of 1-3 mm, mix the crushed petroleum coke and modified pitch at a weight ratio of 10:1, and then put the mixed raw materials into an electric kneader at a kneading temperature of 130°C. Vibrate for 6 minutes;

[0053] (3) The kneaded material was roasted in a tunnel kiln, and the temperature was raised from an initial temperature of 20 °C to 1125 °C at 1 °C / min, and the prebaked electrode was obtained after heat preservation and roasting for 95 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com