Prebaked anode and its preparation method and application

A pre-baked anode and roasting technology, applied in the field of electrolysis, can solve the problems of easy oxidation and insufficient mechanical strength of the pre-baked anode, and achieve the effect of improving the residual pole rate and wide adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

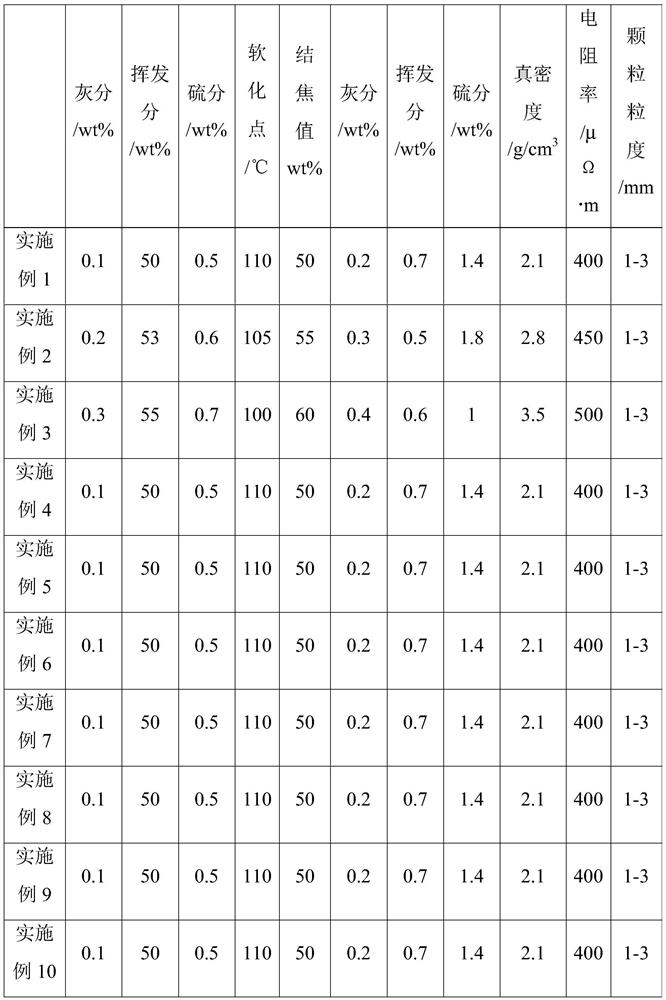

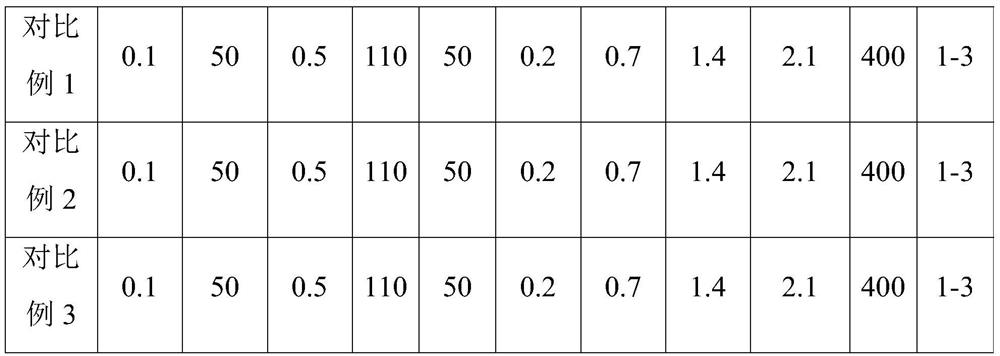

Embodiment 1

[0043] (1) Modify the asphalt according to the ratio in Table 2, the modification temperature is 175°C, shear 20min at a speed of 2955r / min, and stir for 2h to obtain modified asphalt;

[0044] (2) Crush the petroleum coke to a particle size of 1-3 mm, mix the crushed petroleum coke and modified pitch at a weight ratio of 8:1, and then put the mixed raw materials into an electric kneader with a kneading temperature of 120°C. Vibrate for 5 minutes;

[0045] (3) The kneaded material was roasted in a tunnel kiln, and the temperature was raised from an initial temperature of 20 °C to 1100 °C at a rate of 0.5 °C / min, and the prebaked electrode was obtained after heat preservation and roasting for 80 hours.

Embodiment 2

[0047] (1) Modify the asphalt according to the ratio in Table 2, the modification temperature is 165°C, the shearing time is 15min at 2955r / min, and the mixture is stirred for 3h to obtain the modified asphalt;

[0048](2) Crush the petroleum coke to a particle size of 1-3 mm, mix the crushed petroleum coke and modified pitch at a weight ratio of 12:1, and then put the mixed raw materials into an electric kneader at a kneading temperature of 150°C. Vibrate for 8 minutes;

[0049] (3) The kneaded material is roasted in a tunnel kiln, the initial temperature is raised from 20 °C to 1150 °C at 1 °C / min, and the prebaked electrode is obtained after heat preservation and roasting for 90 hours.

Embodiment 3

[0051] (1) Modify the asphalt according to the ratio in Table 2, the modification temperature is 180°C, shear 18min at 2968r / min, stir for 4h, and obtain modified asphalt;

[0052] (2) Crush the petroleum coke to a particle size of 1-3 mm, mix the crushed petroleum coke and modified pitch at a weight ratio of 10:1, and then put the mixed raw materials into an electric kneader at a kneading temperature of 130°C. Vibrate for 6 minutes;

[0053] (3) The kneaded material was roasted in a tunnel kiln, and the temperature was raised from an initial temperature of 20 °C to 1125 °C at 1 °C / min, and the prebaked electrode was obtained after heat preservation and roasting for 95 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com