A quenching and tempering treatment method for controlling heavy metal pollution in printing and dyeing sludge co-firing project

A technology for printing and dyeing sludge, quenching and tempering treatment, applied in water/sludge/sewage treatment, sludge treatment, combustion methods, etc., can solve the problems of high cost and limited increase in the residual rate of heavy metals, and reduce secondary pollution. , the effect of improving the residual rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

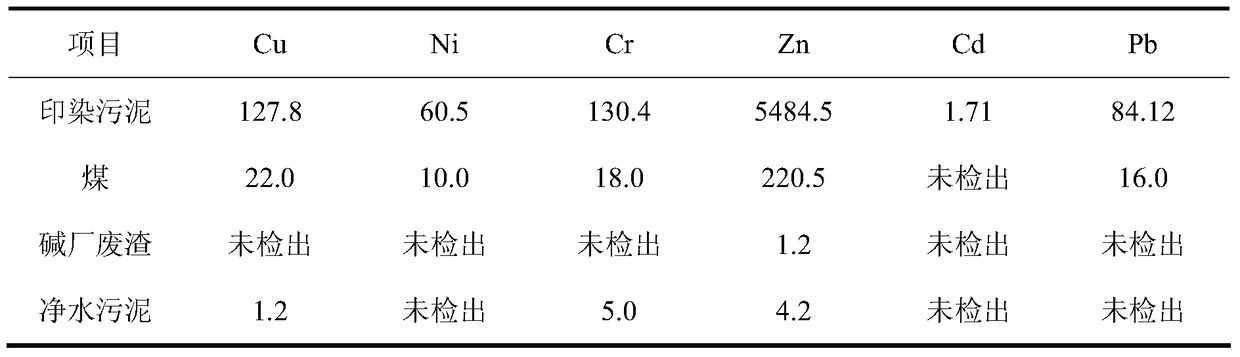

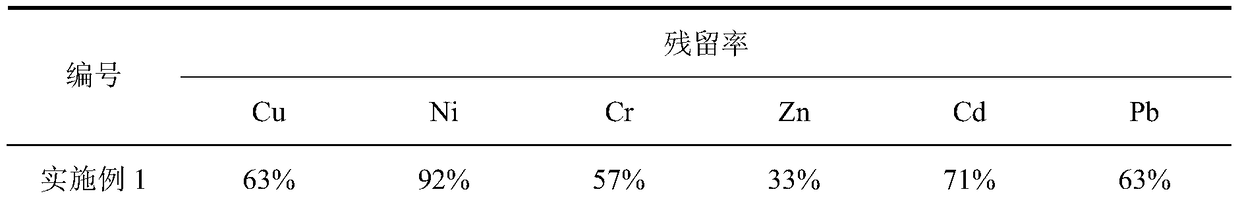

[0014] In terms of mass fraction, 3% of alkali plant waste residue, 1% of water purification sludge, 15% of printing and dyeing sludge and 81% of coal, mix the alkali plant waste residue, water purification sludge, printing and dyeing sludge and coal according to the above contents evenly as Thermal power station chain boiler fuel incineration treatment. Control the boiler furnace temperature to 900-1000°C to obtain slag.

Embodiment 2

[0016] In terms of mass fraction, 1% of alkali plant waste residue, 3% of water purification sludge, 15% of printing and dyeing sludge and 81% of coal, mix the alkali plant waste residue, water purification sludge, printing and dyeing sludge and coal according to the above contents evenly as Thermal power station chain boiler fuel incineration treatment. Control the boiler furnace temperature to 900-1000°C to obtain slag.

Embodiment 3

[0018] In terms of mass fraction, 2% of alkali plant waste residue, 1% of water purification sludge, 5% of printing and dyeing sludge and 92% of coal, the alkali plant waste residue, water purification sludge, printing and dyeing sludge and coal are mixed evenly according to the above contents and used as Thermal power station chain boiler fuel incineration treatment. Control the boiler furnace temperature to 900-1000°C to obtain slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com