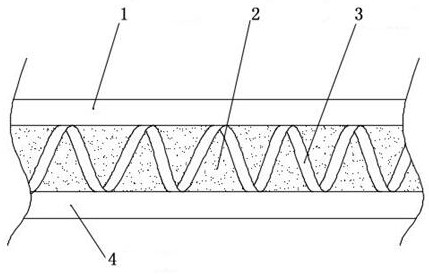

Environment-friendly water-based ink, and environment-friendly high-strength compression-resistant color box and manufacturing method thereof

A water-based ink, environmental protection technology, applied in the direction of ink, chemical instruments and methods, lamination, etc., can solve problems such as difficult to guarantee quality, achieve the effect of ensuring aesthetics and user experience, reducing environmental pollution, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

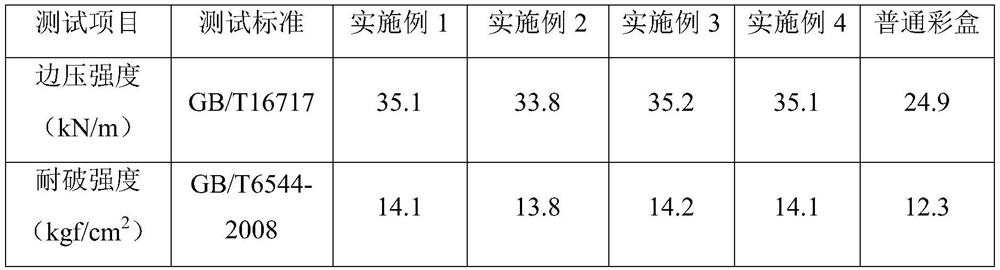

Examples

Embodiment 1

[0060] A kind of environment-friendly water-based ink, is made from the raw material that comprises following parts by weight:

[0061] 28 parts of epoxy-acrylic resin,

[0062] Fluorosilicone modified acrylate emulsion 12 parts,

[0063] 7 parts of hydroxycellulose,

[0064] 10 parts of colorant,

[0065] 20 parts of nano calcium carbonate,

[0066] 2 parts of cerium dioxide,

[0067] Butyl cellosolve 10 parts,

[0068] 10 parts of triethanolamine,

[0069] 0.5 part of defoamer,

[0070] 0.6 parts of sodium hexametaphosphate,

[0071] Trimethoprim 0.5 part,

[0072] 1.2 parts of additives,

[0073] 15 parts of deionized water,

[0074] 5 parts isopropanol.

[0075] The purity of the ceria of the present embodiment is 99.9-99.99%, and the density is 7.13-7.15g / cm 3 .

[0076] The preparation technology of the auxiliary agent of the present embodiment comprises the following steps:

[0077] Step 1. In N 2 Add nano-titanium dioxide into water and stir under the atmo...

Embodiment 2

[0091] A kind of environment-friendly water-based ink, is made from the raw material that comprises following parts by weight:

[0092] 35 parts of epoxy-acrylic resin,

[0093] Fluorosilicone modified acrylate emulsion 11 parts,

[0094] 8 parts of hydroxycellulose,

[0095] 20 parts of colorant,

[0096] 15 parts of nanometer calcium carbonate,

[0097] 3 parts of cerium dioxide,

[0098] Butyl cellosolve 5 parts,

[0099] 8 parts of triethanolamine,

[0100] 0.6 parts of defoamer,

[0101] 0.7 parts of sodium hexametaphosphate,

[0102] Trimethoprim 0.9 parts,

[0103] 0.5 parts of additives,

[0104] 22 parts of deionized water,

[0105] 3 parts isopropanol.

[0106] The purity of the ceria of the present embodiment is 99.9-99.99%, and the density is 7.13-7.15g / cm 3 .

[0107] The preparation technology of the auxiliary agent of the present embodiment comprises the following steps:

[0108] Step 1. In N 2 Add nano-titanium dioxide to water under atmosphere a...

Embodiment 3

[0122] A kind of environment-friendly water-based ink, is made from the raw material that comprises following parts by weight:

[0123] 25 parts of epoxy-acrylic resin,

[0124] Fluorosilicone modified acrylate emulsion 15 parts,

[0125] 6 parts of hydroxycellulose,

[0126] 30 parts of colorant,

[0127] 5 parts of nanometer calcium carbonate,

[0128] 2.5 parts of cerium dioxide,

[0129] 6 parts of triethanolamine,

[0130] 0.7 part of defoamer,

[0131] Sodium hexametaphosphate 1.0 part,

[0132] Trimethoprim 1.0 parts,

[0133] Auxiliary 1.0 parts,

[0134] 25 parts of deionized water,

[0135] 4 parts isopropanol.

[0136] The purity of the ceria of the present embodiment is 99.9-99.99%, and the density is 7.13-7.15g / cm 3 .

[0137] The preparation technology of the auxiliary agent of the present embodiment comprises the following steps:

[0138] Step 1. In N 2 Add nano-titanium dioxide into water and stir under the atmosphere, add ammonia water after heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com