Patents

Literature

35results about How to "Optimize raw material content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

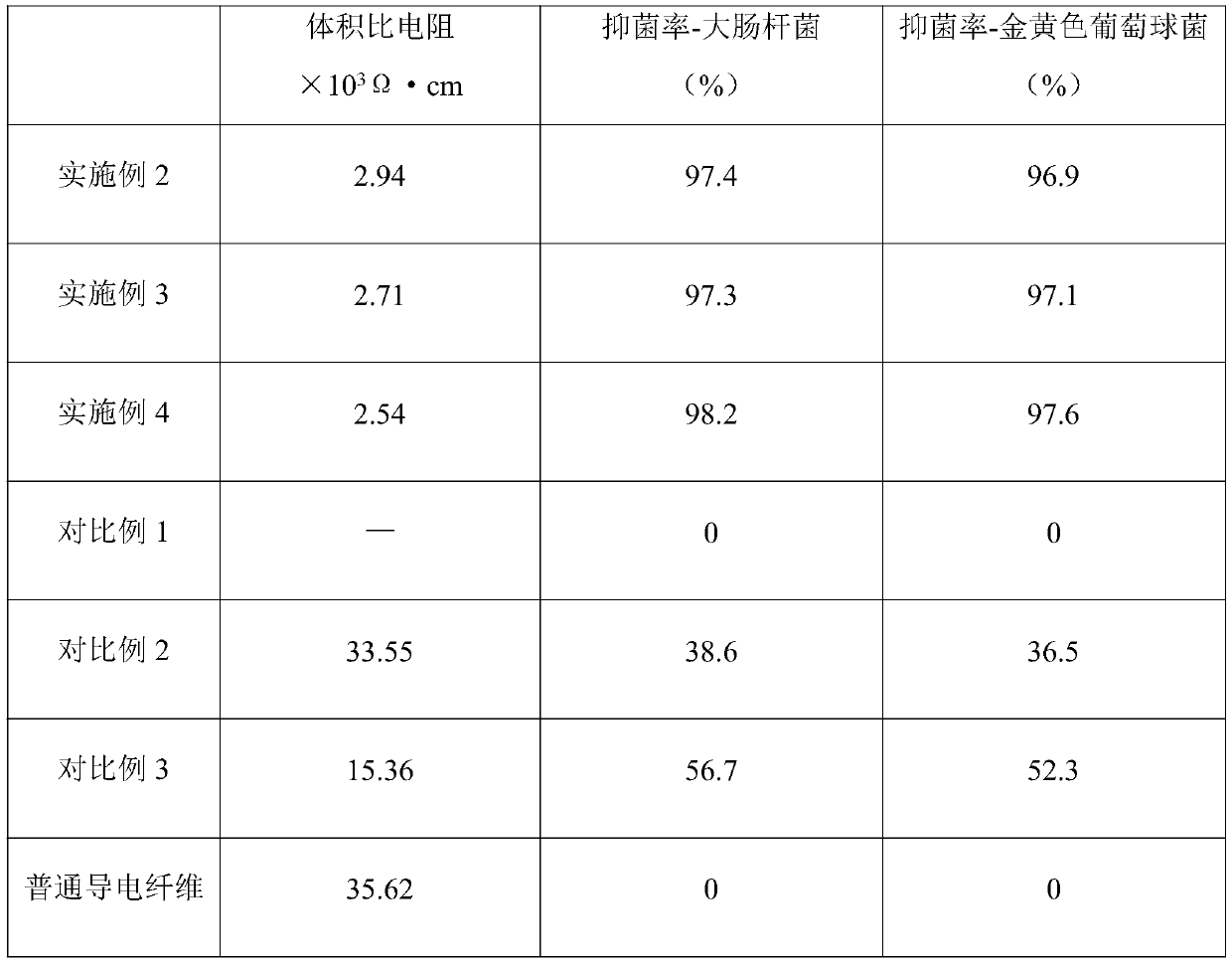

Graphene-reinforced antistatic antibacterial composite fiber and preparation method thereof

InactiveCN110453309ASimple processSimple and fast operationElectroconductive/antistatic filament manufactureFilament/thread formingFiberPolyamide

The invention discloses a graphene-reinforced antistatic antibacterial composite fiber. The fiber comprises an inner layer and an outer layer; the outer layer wraps the periphery of the inner layer, and the cross section outline of the outer layer is in a round shape; the ratio of areas of the cross sections of the inner layer and the outer layer is 1:(0.4-0.7); the inner layer is prepared from, by weight, 80-90 parts of m-benzoylhexanediamine-p-benzoylhexanediamine copolyamide and 10-25 parts of polydecamethylene sebacamide; the outer layer is prepared from, by weight, 85-95 parts of polydecamethylene sebacamide, 15-20 parts of m-benzoylhexanediamine-p-benzoylhexanediamine copolyamide, 6-9 parts of edge graphene oxide and 3-5 parts of a dispersing agent. The graphene-reinforced antistaticantibacterial composite fiber has the good mechanical strength, and keeps good dimensional stability and good antistatic and antibacterial properties, and the fiber is soft and low in water absorption and has the good appearance.

Owner:泰能环保科技(浙江)有限公司

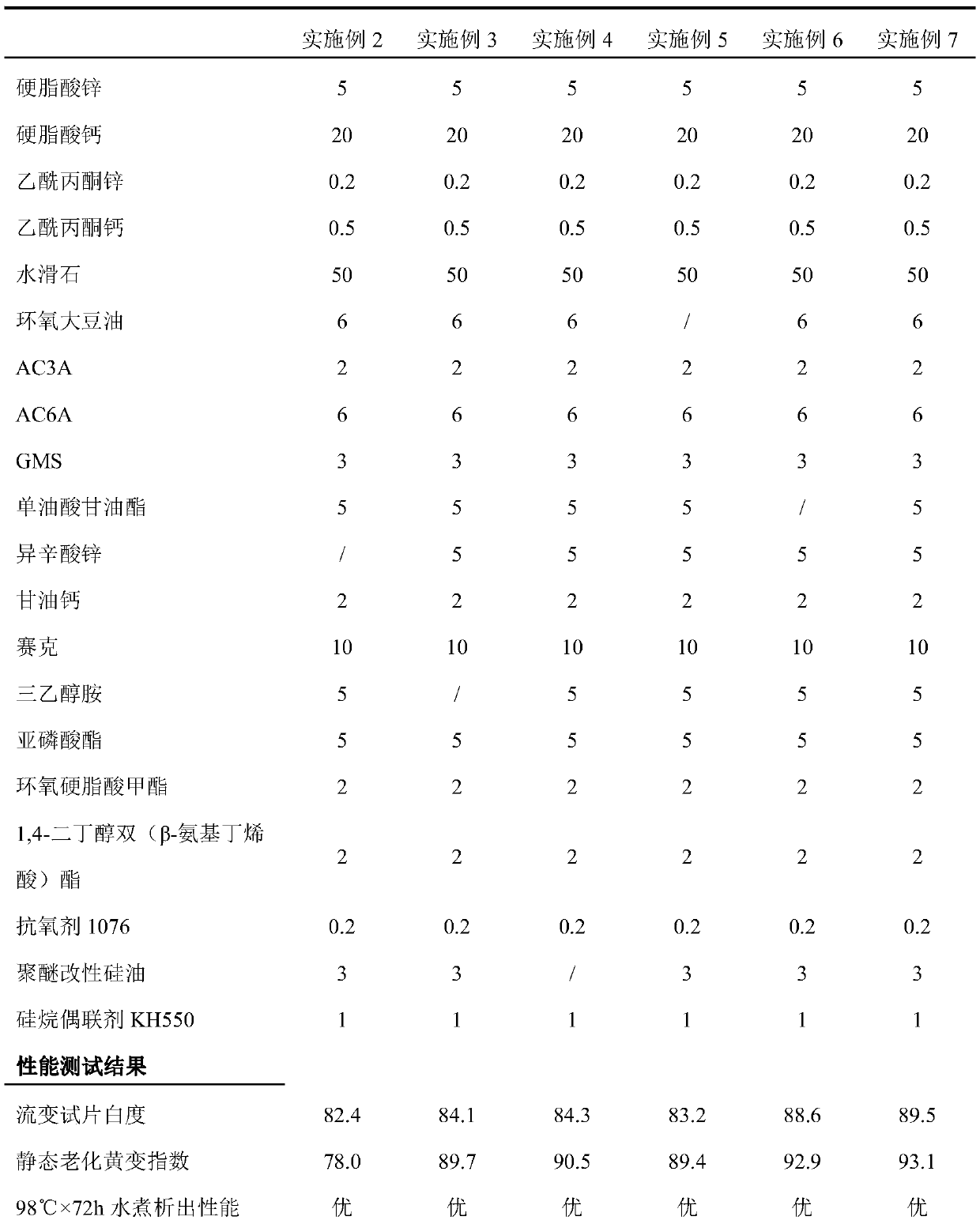

Method for preparing calcium-zinc stabilizer for shoe materials

InactiveCN110698867AReduce dustGuaranteed whiteness and yellowing resistanceSOYBEAN SEED OILAcetylacetone

The invention discloses a method for preparing a calcium-zinc stabilizer for shoe materials. The method comprises the following steps: S1. separately weighing 1-10 parts of zinc stearate, 10-25 partsof calcium stearate, 0.1-2 parts of zinc acetylacetone, 0.5-3 parts of calcium acetylacetonate, 20-50 parts of brucite, 5-15 parts of epoxidized soybean oil, 2-16 parts of lubricant, 5-20 parts of other metal soap, 5-25 parts of organic auxiliary heat stabilizer, 1-10 parts of unsaturated acid ester, 0.1-2 parts of antioxidant and 1-5 parts of dispersant; and S2. firstly, uniformly mixing variouspowder materials, then, adding a liquid ingredient, i.e., the epoxidized soybean oil, the lubricant and the dispersant, and continuing to carry out stirring until the material is of a wet powder or paste mixture, thereby obtaining the calcium-zinc stabilizer for the shoe materials. The calcium-zinc stabilizer for the shoe materials, prepared by the method, is free of organic lead salts and the like, thereby being environmentally friendly and safe; flying of dust can be effectively lowered; the whiteness and yellowing resistance of the shoe materials can be better guaranteed; the calcium-zinc stabilizer is difficult to separate out; and the color fastness and the like of the shoe materials can be improved.

Owner:浙江杰上杰新材料股份有限公司

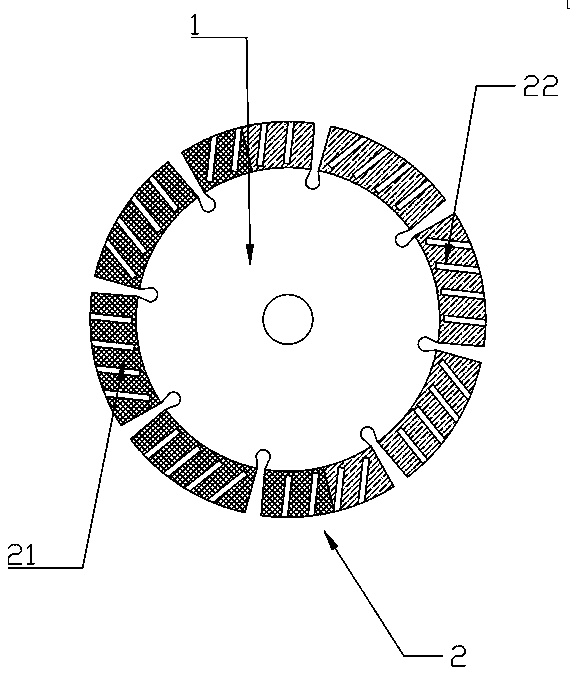

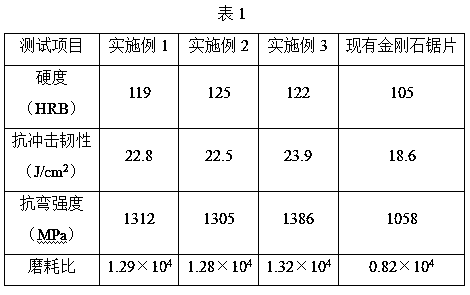

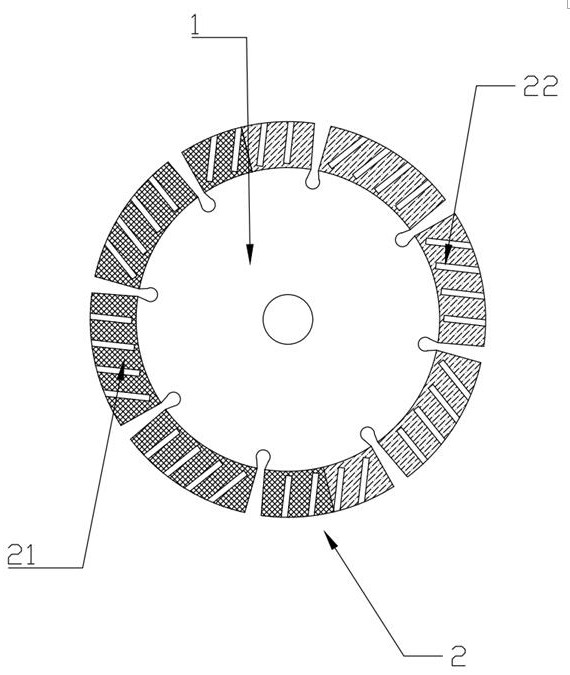

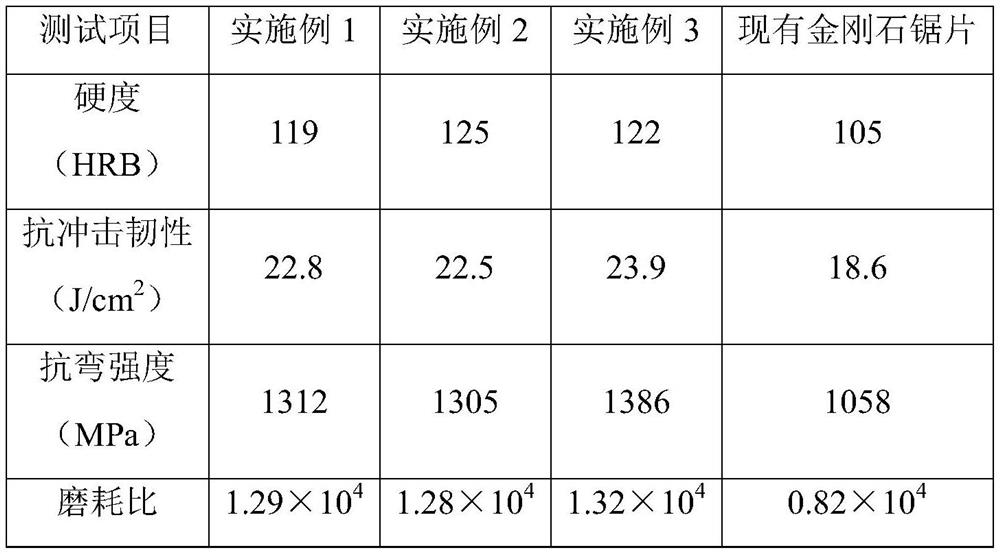

High-performance diamond saw blade and preparation method thereof

ActiveCN109175388AHigh hardnessImprove impact toughnessMetal sawing tool makingMetal sawing toolsIron powderBoron carbide

The invention discloses a high-performance diamond saw blade and a preparation method thereof. A tool bit of the high-performance diamond saw blade comprises a first cutting area and a second cuttingarea. The first cutting area comprises, by weight part, 8-14 parts of polycrystalline diamond particles, 48-55 parts of iron powder, 25-32 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-5 parts of tungsten carbide and titanium carbide mixture powder and 0.4-0.7 part of lanthanum pentanickel powder. The second cutting area comprises, by weight part, 10-16 parts of polycrystalline diamond and boron carbide mixture particles, 45-50 parts of iron powder, 27-33 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-4 parts of titanium carbide powder and 0.4-0.7 part of lanthanum pentanickel powder. The high-performance diamond saw blade is excellent in comprehensive performance.

Owner:泉州市华兴超硬工具有限公司

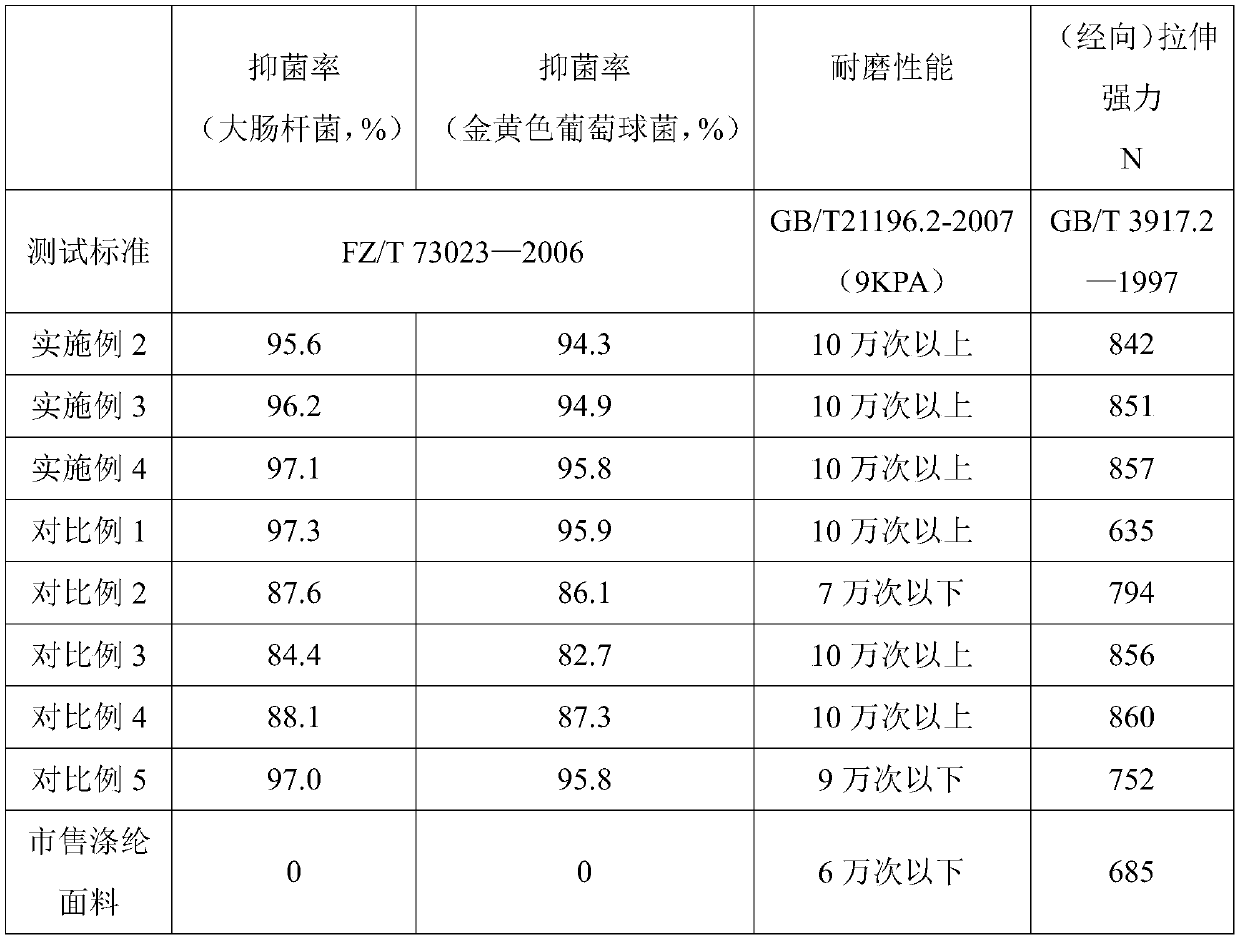

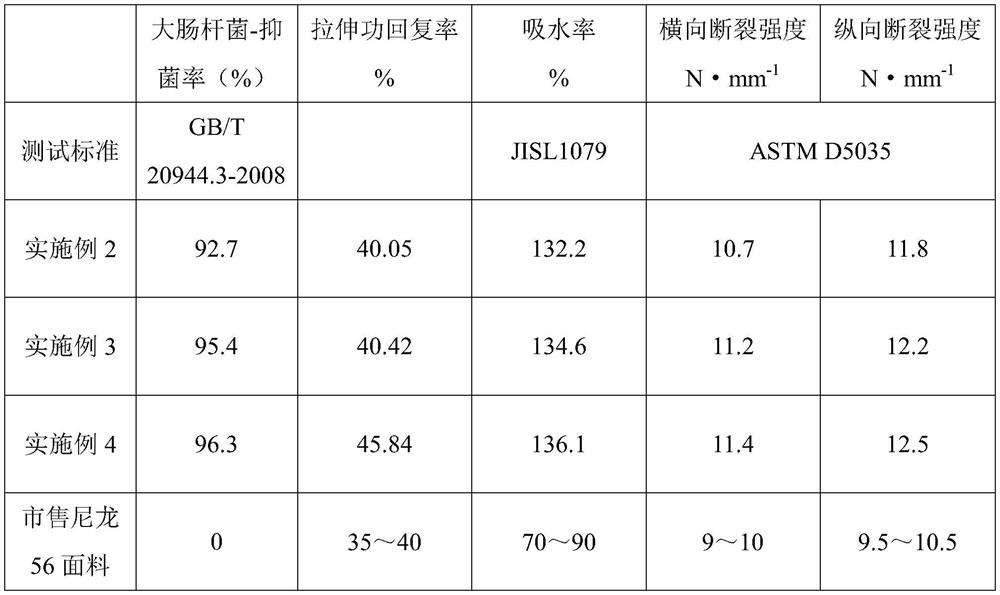

Antibacterial chitosan fabric and preparation method and product thereof

InactiveCN111020727AHigh antibacterial rateImprove antibacterial propertiesWeft knittingWarp knittingPolymer sciencePolyethylene terephthalate glycol

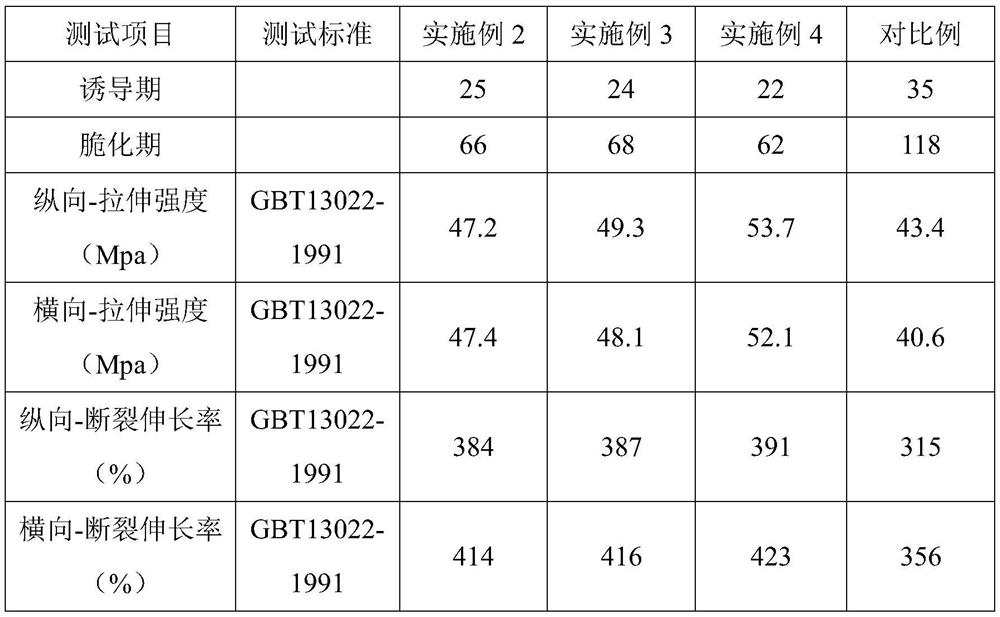

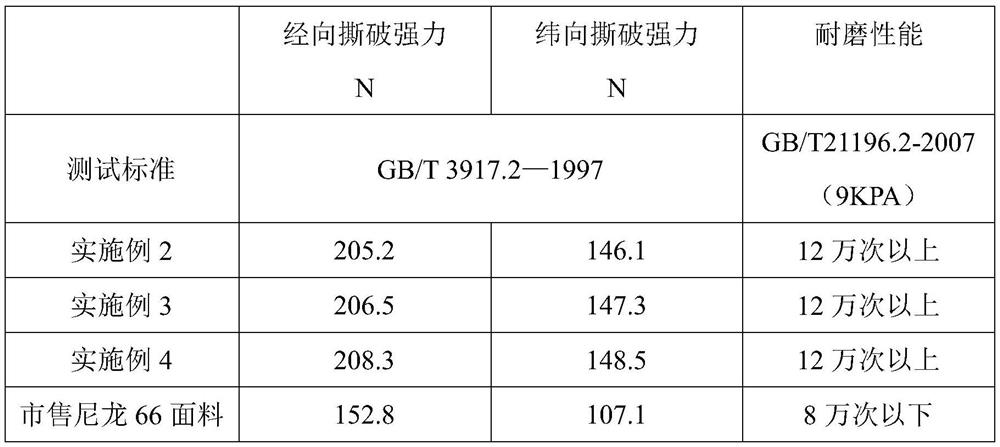

The invention discloses an antibacterial chitosan fabric and a preparation method and product thereof. The antibacterial chitosan fabric is prepared by knitting or weaving skin-core composite filaments; the skin-core composite filaments comprise core layers and skin layers; the skin layers coat the outer surfaces of the core layers, and the cross-sectional profiles of the skin layers are circular;the cross-sectional area ratios of the core layers and the skin layers are 1 : (0.7-0.8); the core layers are prepared from the following raw materials in parts by weight: 90-95 parts of polyethyleneterephthalate and 5-10 parts of polypentanediamine adipate; the skin layers are prepared from the following raw materials in parts by weight: 4-8 parts of polyethylene terephthalate, 86-92 parts of polypentanediamine adipate, 1.6-2.0 parts of nano graphene sheets, 6-9 parts of chitosan, 3-5 parts of diatomite, 3-4 parts of fumed silica and 4-5 parts of a dispersant. The antibacterial chitosan fabric has the advantages of high antibacterial rate, good antibacterial effect, good wear resistance, high tensile strength and good mechanical property.

Owner:卡尔美体育用品有限公司

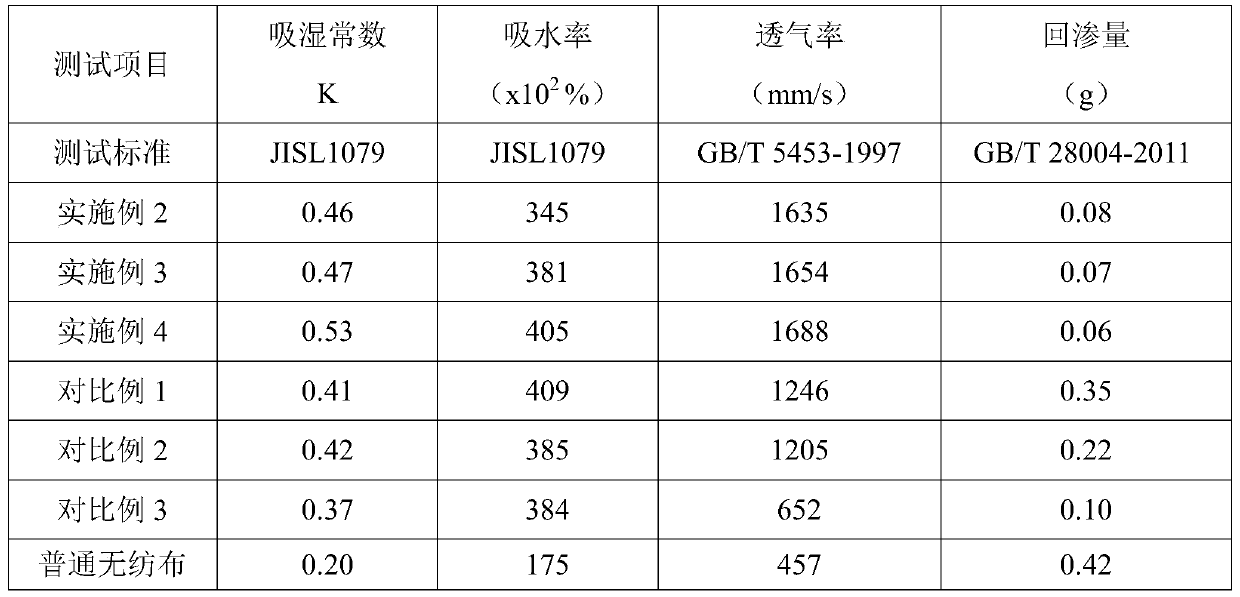

Skin-friendly low-permeability ES composite short fiber for hot air non-woven fabric surface layer and preparation method of skin-friendly low-permeability ES composite short fiber

InactiveCN110055618AIncrease irritationOptimize raw material contentFilament/thread formingConjugated synthetic polymer artificial filamentsFiberIrritation

The invention discloses a skin-friendly low-permeability ES composite short fiber for a hot-air non-woven fabric surface layer. The ES composite short fiber has a skin-core structure and consists of acore layer and a skin layer, wherein the core layer comprises the following raw materials in parts by weight: 85-90 parts of polypropylene, 5-9 parts of ethylene propylene copolymer, 14-18 parts of acrylic acid-acrylamide super absorbent resin and 6-11 parts of inulin; and the skin layer comprises the following raw materials in parts by weight: 80-85 parts of polyethylene, 10-15 parts of methyl methacrylate grafted modified polyethylene, 8-12 parts of ethylene propylene copolymer, 4-7 parts of polyvinyl alcohol, 7-15 parts of superfine pearl powder and 12-17 parts of sodium polyacrylate superabsorbent resin. The skin-friendly low-permeability ES composite short fiber for the hot air non-woven fabric surface layer has the advantages of skin-friendly property, moisture absorption, breathability, elasticity, no irritation to skin, sanitation, antibiosis and the like; and the amount of reverse osmosis after water absorption is small, and the skin-friendly low-permeability ES composite short fiber belongs to the low reverse osmosis type.

Owner:福建省福地化纤科技有限公司

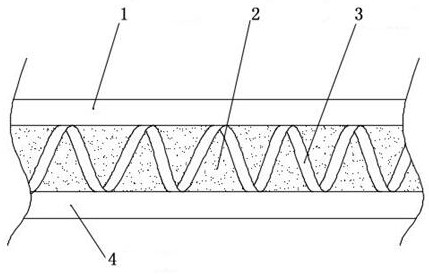

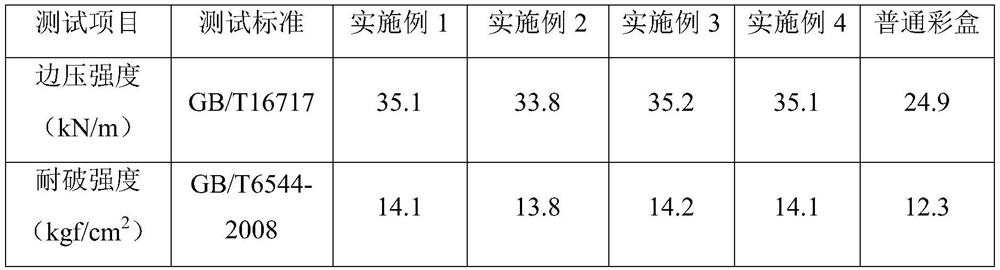

Environment-friendly water-based ink, and environment-friendly high-strength compression-resistant color box and manufacturing method thereof

The invention discloses environment-friendly water-based ink, and an an environment-friendly high-strength compression-resistant color box and a manufacturing method thereof. The environment-friendlywater-based ink is prepared from the following raw materials in parts by weight: 25-35 parts of epoxy acrylic resin, 10-15 parts of fluorosilicone modified acrylate emulsion, 5-8 parts of hydroxy cellulose, 10-30 parts of colorant, 5-20 parts of nano calcium carbonate, 1-3 parts of cerium dioxide, 0-11 parts of butyl cellosolve, 5-10 parts of triethanolamine, 0.5-0.8 part of defoamer, 0.5-1.0 partof sodium hexametaphosphate, 0.5-1.1 parts of trimethoprim, 0.5-1.5 parts of an auxiliary agent, 15-25 parts of deionized water and 3-5 parts of isopropanol. According to the invention, the corrugated paper of the middle layer of the color box is folded into a corrugated structure, so that the stability of the structure of the middle layer is improved, and the situation that the corrugated paperis impacted and deformed, and consequently the corrugated structure in the corrugated paper is damaged is reduced.

Owner:晋江市顺力纸箱有限公司

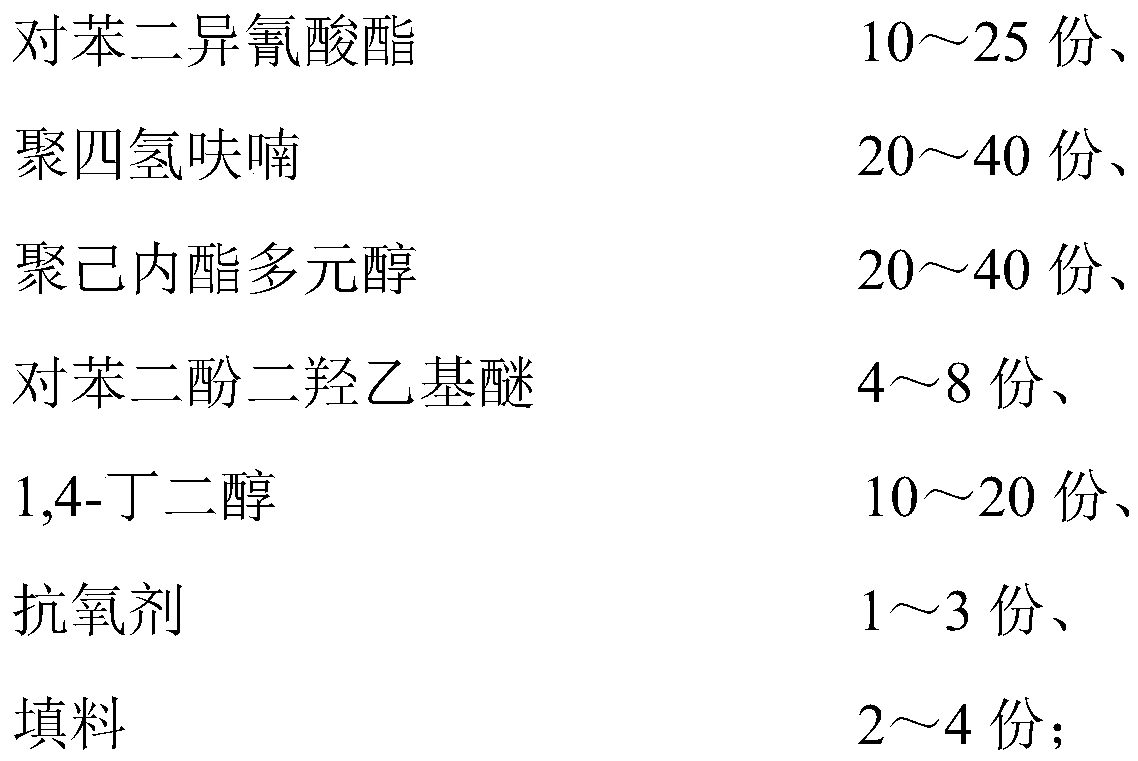

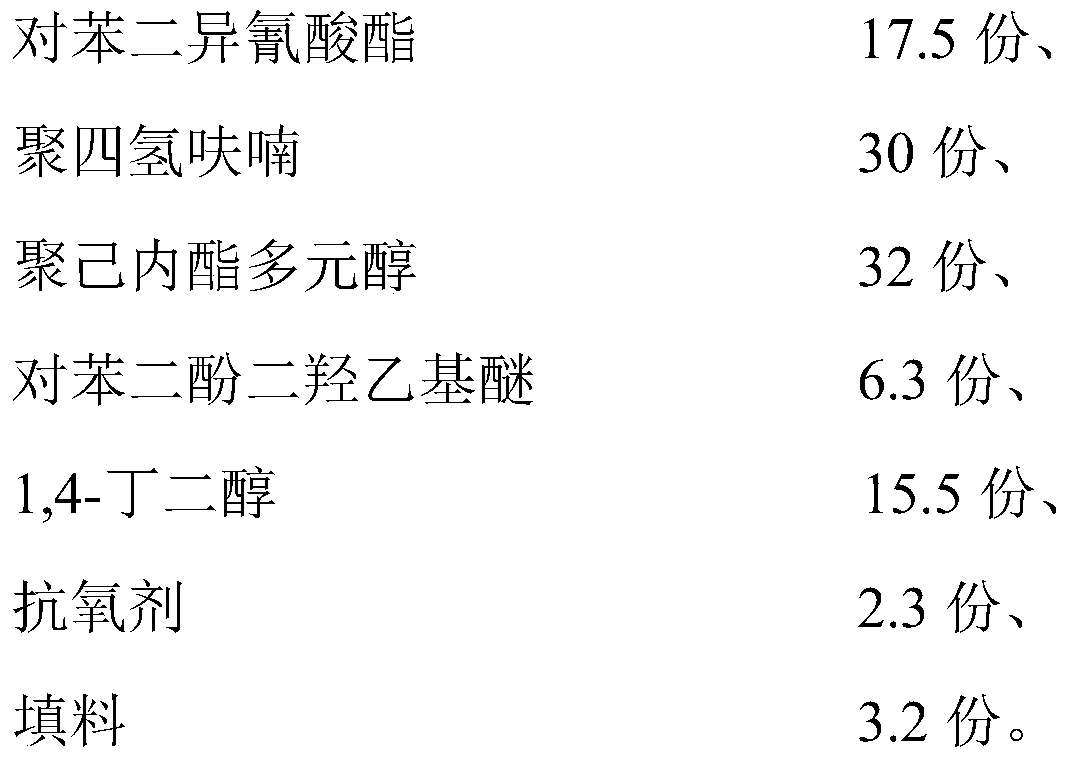

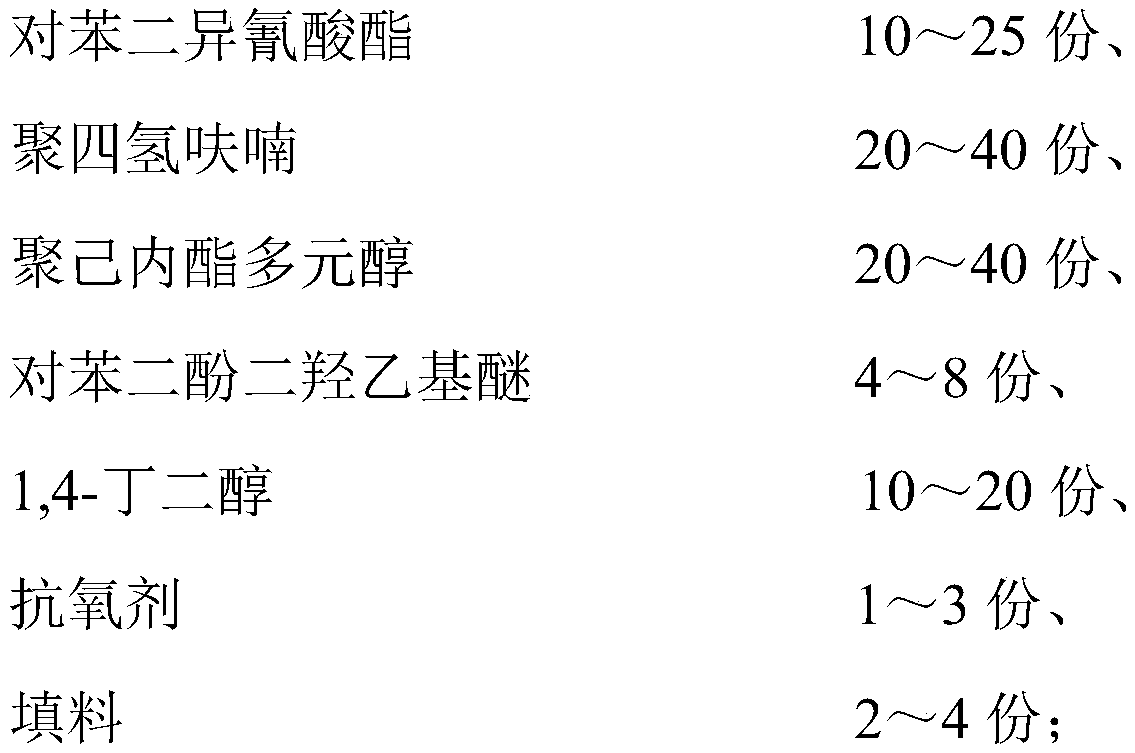

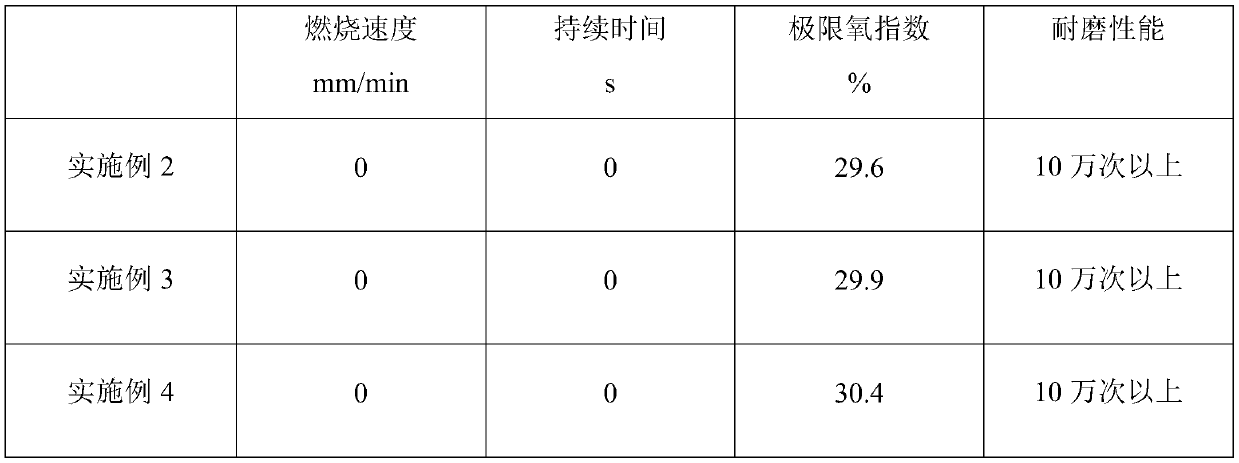

Formula and preparation process for low-temperature-resistant high-elasticity polyurethane used for sealing

The invention discloses a formula for low-temperature-resistant high-elasticity polyurethane used for sealing. The formula comprises the following raw materials by weight: 10-25 parts of p-phenylene diisocyanate, 20-40 parts of polytetrahydrofuran, 20-40 parts of polycaprolactone polyol, 4-8 parts of hydroquinone bis(2-hydroxyethyl)ether, 10-20 parts of 1,4-butanediol, 1-3 parts of an antioxidantand 2-4 parts of a filler, wherein the relative molecular mass of the polytetrahydrofuran is 1400-2000, and the relative molecular mass of the polycaprolactone polyol is 1800-2200. Theow-temperature-resistant high-elasticity polyurethane used for sealing prepared by the invention has good low-temperature resistance and high elasticity, is expanded in the range of use temperature and not liable tothermal ageing, and can be injection-molded.

Owner:上海唯万密封科技股份有限公司

High-wear-resistant flame-retardant fabric and preparation method thereof

PendingCN110983484AGood flame retardant performanceGood wear resistanceWeft knittingFlame-proof filament manufactureDiaminePolyethylene terephthalate glycol

The invention discloses a high-wear-resistant flame-retardant fabric which is prepared from high-wear-resistant flame-retardant fibers through a knitting process. The high-wear-resistant flame-retardant fibers are prepared from the raw materials in parts by weight: 70-78 parts of polyethylene terephthalate, 16-20 parts of poly (adipic acid-1,5-diaminopentane), 10-14 parts of phenyl ether siliconerubber, 1.8-2.2 parts of nano-graphene sheets, 2-3 parts of glass fibers, 2-3 parts of fumed silica, 3-5 parts of a dispersant and 4-6 parts of polysaccharide sodium phosphate. The high-wear-resistantflame-retardant fabric prepared by selecting layers of raw materials, the content of each raw material is optimized, and the high-wear-resistant flame-retardant fabric prepared from the high-wear-resistant flame-retardant fibers through the knitting process is good in flame retardancy, excellent in wear resistance, free of odor, soft in hand feeling and good in resilience.

Owner:ZHEJIANG SHENGLI TEXTILE CO LTD

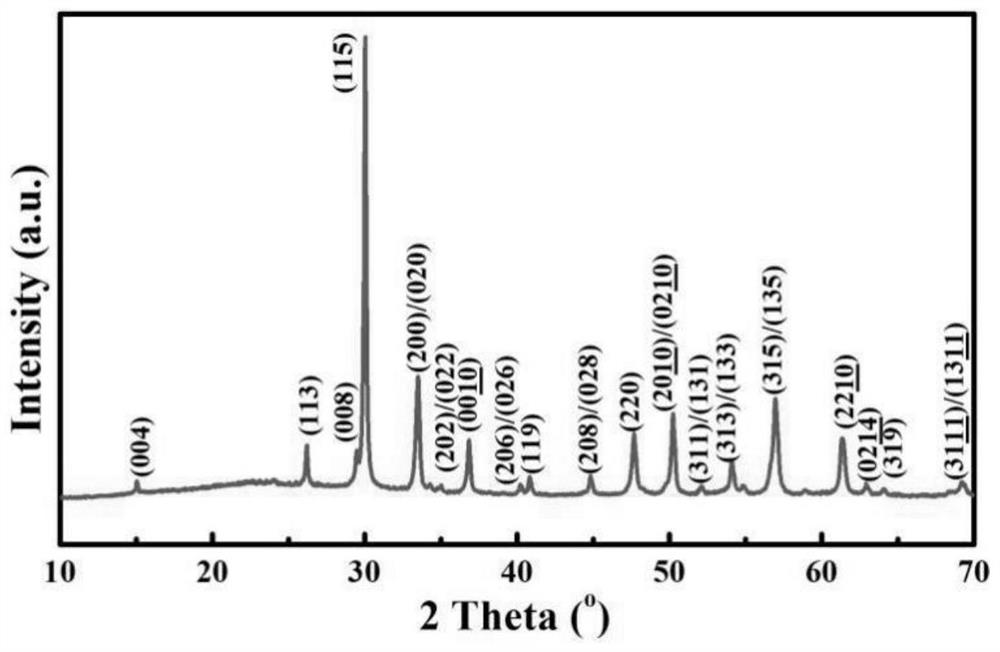

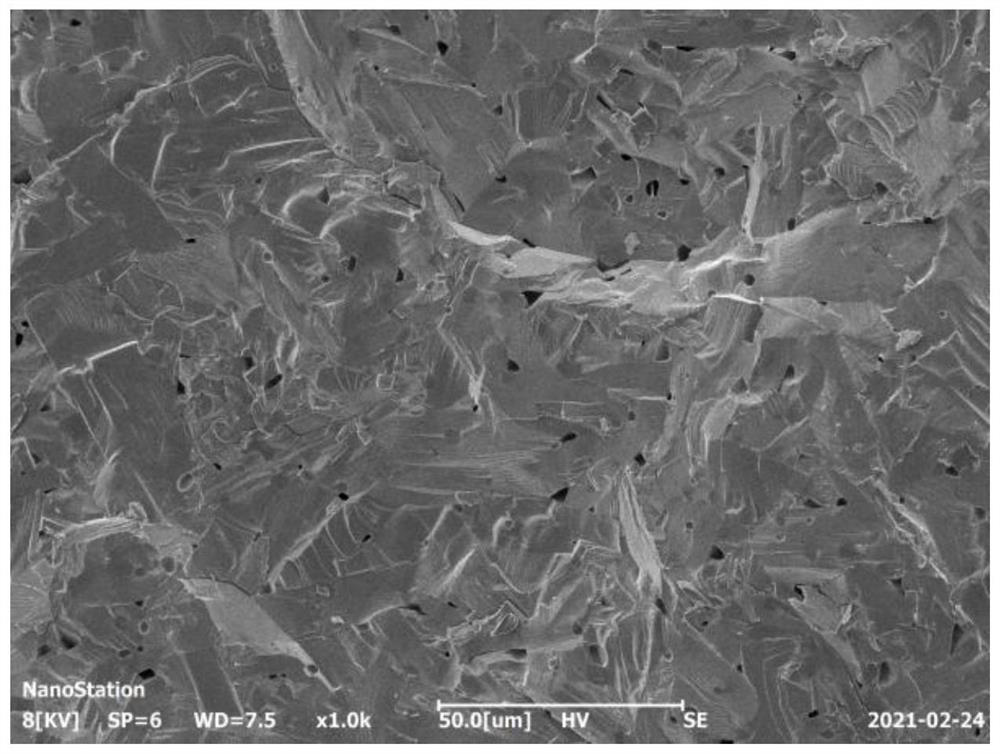

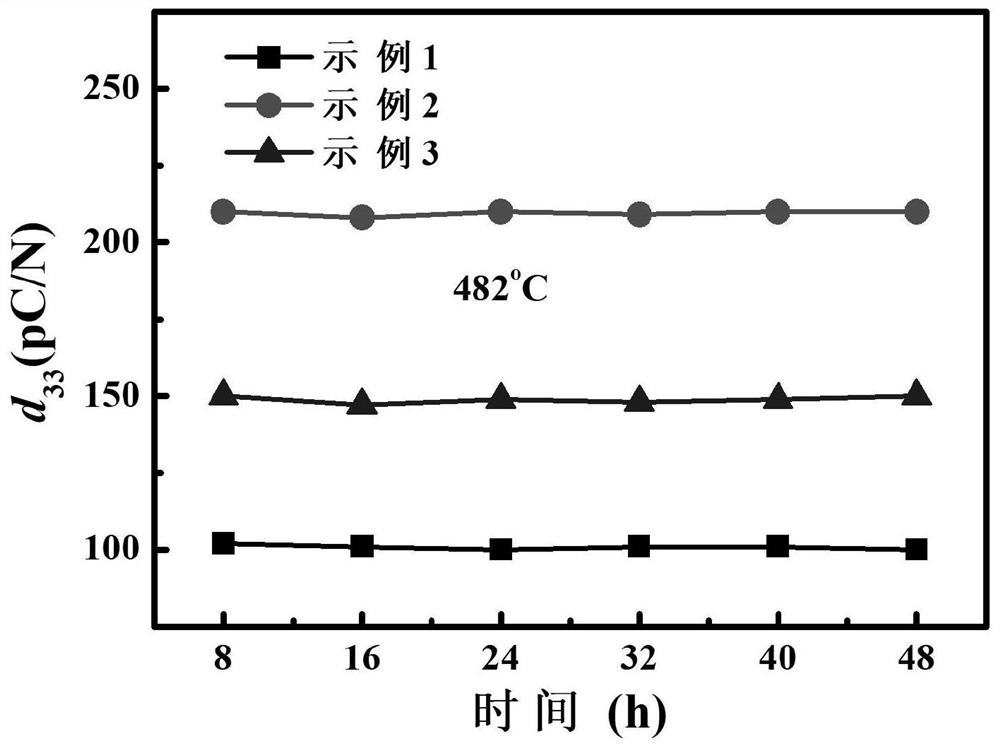

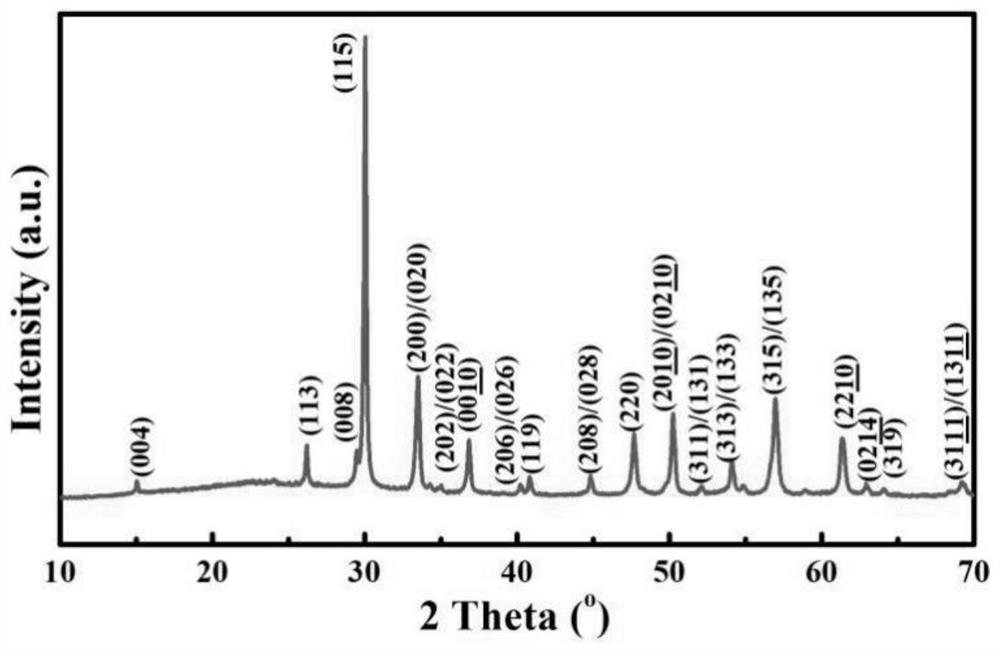

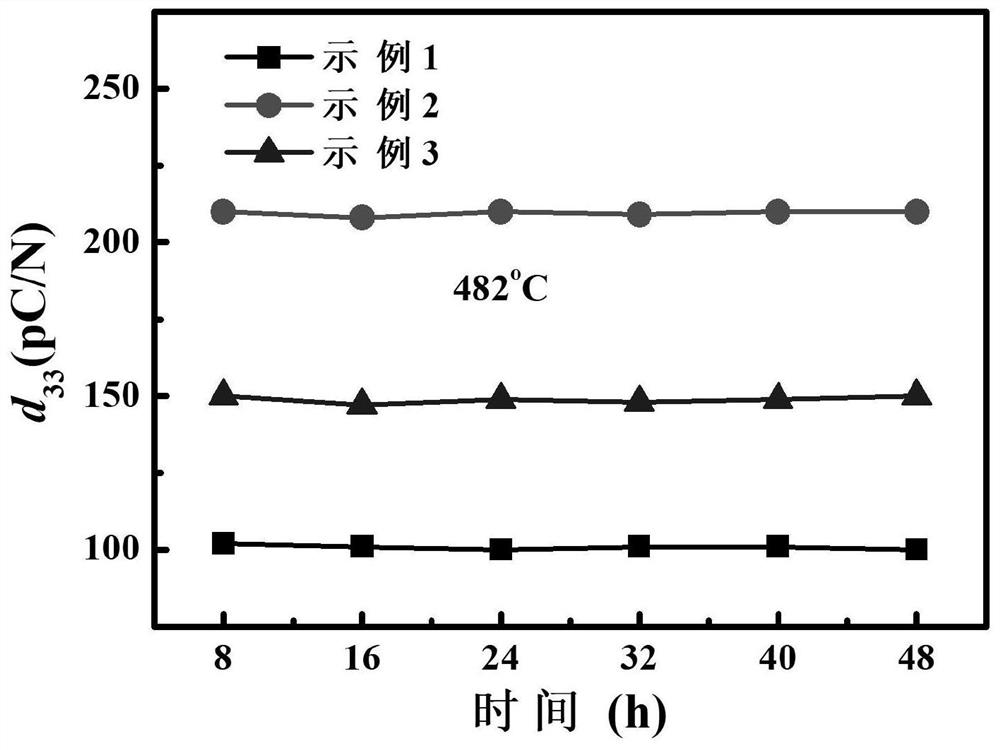

Preparation method of multilayer piezoelectric ceramic used in high-temperature environment of 482 DEG C

The invention discloses a preparation method of a multilayer piezoelectric ceramic used in a 482 DEG C high-temperature environment. The preparation method mainly comprises the following steps: uniformly stirring high-temperature ceramic powder, a solvent, a dispersing agent, a binder and a thickening agent by using a stirrer to prepare tape casting slurry; forming a film with a certain thickness through a casting machine, printing an inner electrode, and printing an outer electrode after isostatic pressing lamination; and discharging glue at a low heating rate and sintering the ceramic at a low temperature. The piezoelectric property tends to be stable through ceramic polarization and high-temperature aging. The multilayer piezoelectric ceramic prepared by the preparation method of the multilayer piezoelectric ceramic used in the high-temperature environment of 482 DEG C can meet the use requirements of the high-temperature environment, is good in piezoelectric property, can be completely used in the high-temperature environment of 482 DEG C, and is stable in piezoelectric property after long-time heat preservation at the high temperature of 482 DEG C; and the performance is stable after aging at a high temperature of 550 DEG C, and the use requirement in a high-temperature environment is met.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG +4

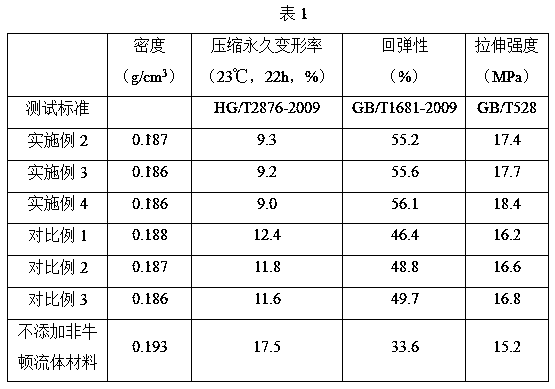

Non-Newtonian fluid material for shoe material and preparation method thereof

The invention discloses a non-Newtonian fluid material for a shoe material and a preparation method of the non-Newtonian fluid material. The non-Newtonian fluid material is prepared from the followingraw materials in parts by weight: 75-85 parts of methyl silicone oil, 17-23 parts of vinyl silicone oil, 2-3 parts of hydrogen-containing silicone oil, 0.9-1.1 parts of a platinum catalyst, 8.5-11.5parts of white carbon black and 17-23 parts of tapioca flour. When the non-Newtonian fluid material disclosed by the invention is applied to an EVA / TPU supercritical foaming composite material, resilience can be greatly improved, permanent compression set ratio is reduced, therefore, after the EVA / TPU supercritical foaming shoe material uses the non-Newtonian fluid material provided by the invention, and when the shoe material is slightly pressed (namely the shoe material bears small force), the shoe material is soft, large in generated deformation and comfortable to wear, and when the shoe material is heavily pressed (namely the shoe material bears large force), the shoe material is hard, it is guaranteed that deformation is not too large, excessive deformation is effectively prevented, and the appearance is prevented from being distorted or even cannot be recovered.

Owner:福建安达福新材料科技有限公司

Biodegradable environment-friendly fabric and preparation method and product thereof

InactiveCN111118662AHigh biodegradation ratePromote degradationWeft knittingWarp knittingPolyesterPolymer science

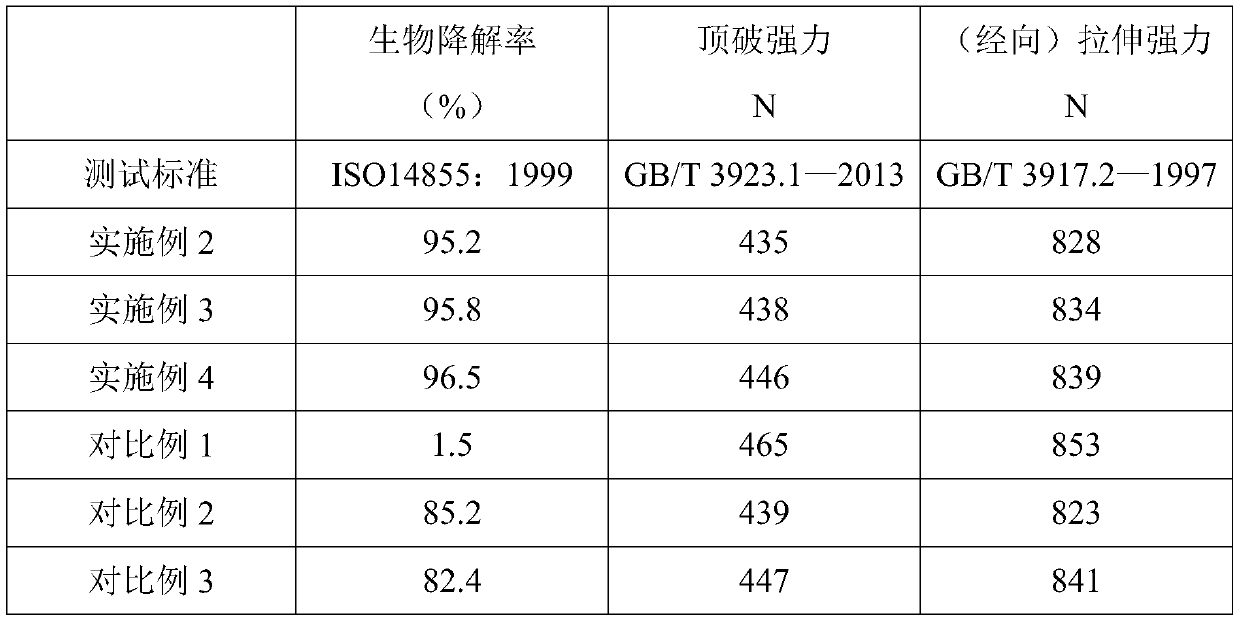

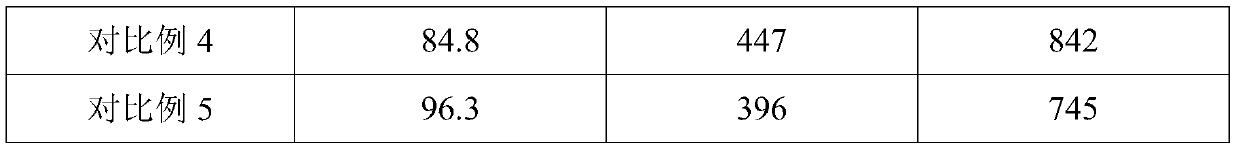

The invention discloses a biodegradable environment-friendly fabric and a preparation method and product thereof. The biodegradable environment-friendly fabric is made of biodegradable composite fibers through a knitting or machine-weaving process; and the biodegradable composite fibers are prepared from the following raw materials in parts by weight: 60-70 parts of polyethylene terephthalate, 25-32 parts of polybutylene succinate, 10-14 parts of polylactic acid, 5-7 parts of chitosan, and 5-7 parts of fumed silica. The biodegradable environment-friendly fabric is prepared from selected raw materials, the content of each raw material is optimized, the biodegradable environment-friendly fabric made of the biodegradable composite fibers through the knitting or machine-weaving process is highin biodegradation rate, good in biodegradability, environmentally friendly, high in burst strength, (warp direction) high tensile strength close to that of a pure polyester fabric, good in mechanicalproperty, and durable.

Owner:卡尔美体育用品有限公司

Medicine package formula for moxibustion plaster and preparation method of medicine package with formula

InactiveCN110101835AWith warm meridians to stop bleedingDispelling cold and relieving painAntipyreticAnalgesicsActivated carbonSide effect

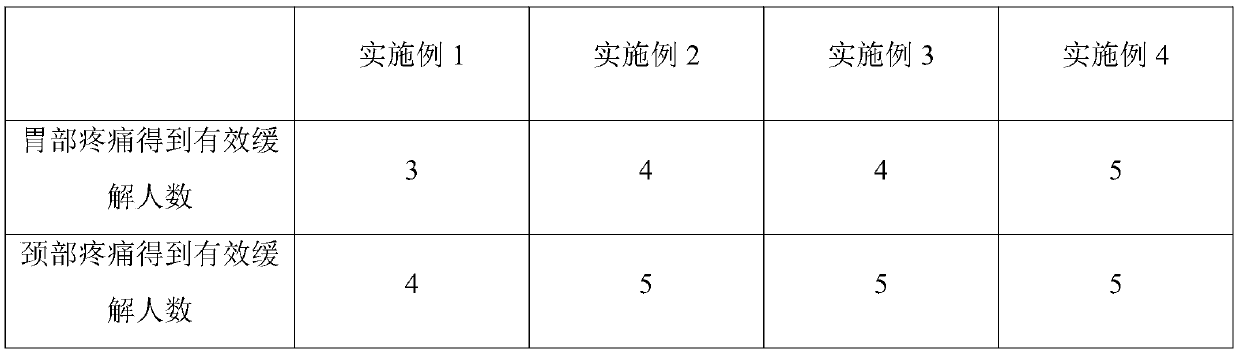

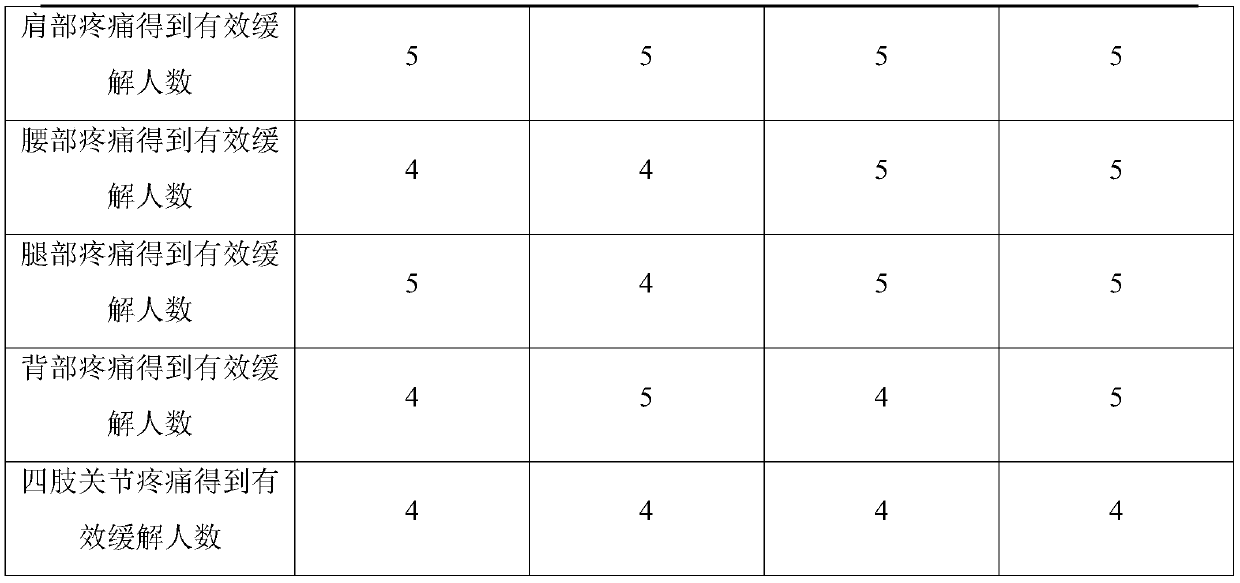

The invention discloses a medicine package formula for a moxibustion plaster. The medicine package is prepared from, by weight, 92-108 parts of an artemisia argyi extract, 0.8-1.2 parts of a dried ginger extract, 22-28 parts of tourmaline heating powder, 35-45 parts of activated carbon, 20-30 parts of vermiculite and 8-13 parts of water absorbing resin. Through screening and comparison, systematicand complete research is carried out according to the national drug management requirements, the compositions of the raw materials are carefully selected, the contents of all the raw materials are optimized, the artemisia argyi extract, the dried ginger extract, the tourmaline heating powder, the activated carbon, the vermiculite and the water absorbing resin in appropriate ratio are selected, the medicine package formula for the moxibustion plaster is obtained, and the medicine package for the moxibustion plaster is prepared; after the corresponding part is subjected to hot compress by adopting the medicine package for the moxibustion plaster, the pain of the parts such as the stomach, the neck, the shoulders, the waist, the legs, the back and the joints of the four limbs can be effectively relieved, the body is not hurt, and no toxic or side effects are caused.

Owner:浙江乾一生物科技有限公司

Negative ion antibacterial ES composite fiber and preparation method thereof

PendingCN113186617AGood antibacterial effectImprove mechanical propertiesFilament/thread formingConjugated synthetic polymer artificial filamentsFiberStaphyloccocus aureus

The invention discloses negative ion antibacterial ES composite fiber and a preparation method thereof. The negative ion antibacterial ES composite fiber has a skin-core structure, that is, the negative ion antibacterial ES composite fiber is composed of a core layer and a skin layer, wherein the core layer comprises the following raw materials in parts by weight of 80-90 parts of polypropylene, 8-11 parts of polyethylene and 12-16 parts of maleic anhydride grafted polypropylene; and the skin layer is prepared from the following raw materials in parts by weight of 70 to 80 parts of polyethylene, 7 to 10 parts of an ethylene-propylene copolymer, 6 to 8 parts of dibutyl maleate grafted polypropylene, 15 to 20 parts of an ethylene-vinyl acetate copolymer, 5 to 6.5 parts of crystal tourmaline powder, 2 to 2.6 parts of opal powder and 1.5 to 2.0 parts of hedera helix powder. The negative ion antibacterial ES composite fiber disclosed by the invention has good antibacterial and bacteriostatic effects on escherichia coli, candida albicans, staphylococcus aureus and the like, has broad-spectrum antibacterial and bacteriostatic effects, and does not contain small-molecular antibacterial agents and heavy metal ions such as silver ions; and the breaking strength is high, the mechanical property is excellent, the durability is good, and the flexibility is good.

Owner:福建省福地化纤科技有限公司

PBAT foamed sheet production process

The invention discloses a PBAT foamed sheet production process. The PBAT foamed sheet production process sequentially comprises the following steps: S1, mixing 2-5 parts by weight of a chain extender, 1-5 parts by weight of a nucleating agent, 1.8-5 parts by weight of a dispersant, 0.1-2 parts by weight of a surfactant and 0.1-2 parts by weight of an antioxidant to obtain a mixture; S2, adding the obtained mixture into 81-95 parts of a PBAT raw material, and uniformly mixing to obtain a mixture I; and S3, adding the mixture I into an extruder for plasticizing and melting, simultaneously injecting a foaming agent for blending, and conveying the mixture I to a molding machine head for molding to obtain the foamed sheet. According to the production process of the PBAT foamed sheet, the raw material composition is selected, the content of each raw material is optimized, and a proper proportion is selected, so that the prepared PBAT foamed sheet based on the supercritical fluid has relatively large cell density, small cell size, uniform cells and excellent impact resistance.

Owner:江苏聚核高分子功能材料研究院有限公司

Alkaline cyanide-free zinc plating additive and preparation method thereof

The invention discloses an alkaline cyanide-free zinc plating additive. The alkaline cyanide-free zinc plating additive is prepared from the raw materials in parts by weight: a main complex, an auxiliary complex, a surfactant and other additives. The main complex is potassium hydrogen tartrate, the auxiliary complex is 2-mercaptobenzimidazole zinc salt, the surfactant is 2-mercaptobenzimidazole, and the other additives are 5-butyl benzotriazole. The alkaline cyanide-free zinc plating additive is a highly efficient alkaline cyanide-free zinc plating additive, after addition and use, the dispersibility and other properties of zinc plating bath are improved, the plating (zinc) layer is smooth, good in gloss and good in corrosion resistance.

Owner:浙江金欣新材料科技股份有限公司

Degradable disposable plastic film and preparation method thereof

ActiveCN110228261AFast degradationHigh tensile strengthSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephtalate

The invention discloses a degradable disposable plastic film. The plastic film comprises a bottom layer and a top layer; the bottom layer is prepared from, by weight, 45-55 parts of polyethylene terephthalate, 25-32 parts of polyethylene, 15-20 parts of maleic anhydride grafted polyethylene, 5-9 parts of lignocellulose, 6-9 parts of hemp fibers, 3.4-4.5 parts of a plasticizer and 16-22 parts of afiller; and the top layer is prepared from, by weight, 22-25 parts of polyethylene terephthalate, 50-55 parts of polyethylene, 14-17 parts of the maleic anhydride grafted polyethylene, 10-15 parts offluorinated plant fibers, 8-12 parts of starch, 5-7 parts of nanometer titanium dioxide, 3.5-4.8 parts of the plasticizer and 12-16 parts of the filler. The degradable disposable plastic film of the invention has the advantages of high degradation rate, high tensile strength, large elongation at break, and good mechanical properties, is not prone tobe damaged during use, and has good user experiences.

Owner:福建冠翔日用塑料制品有限公司

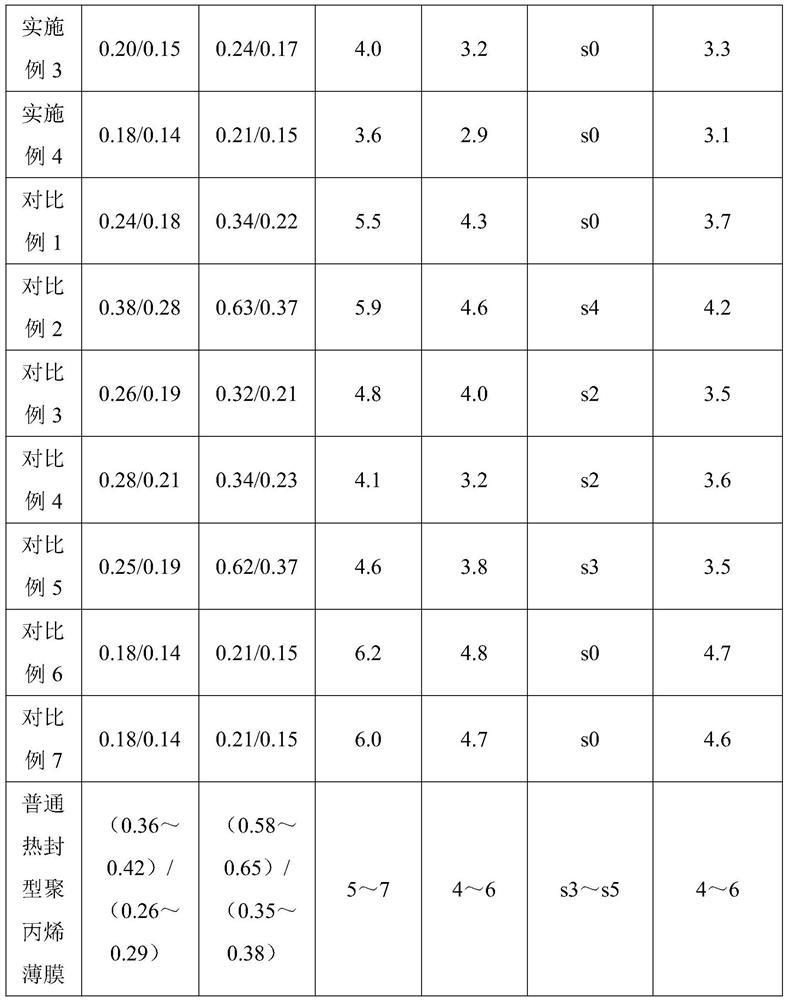

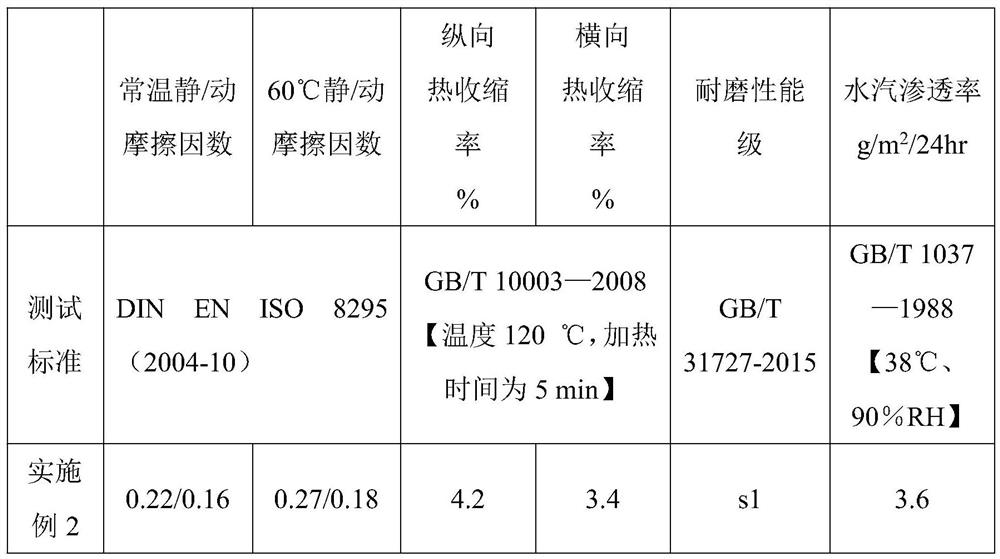

Multi-layer co-extrusion heat-sealing type polypropylene film and preparation method thereof

The invention discloses a multi-layer co-extrusion heat-sealing type polypropylene film. The multi-layer co-extrusion heat-sealing type polypropylene film is prepared by directly co-extruding of a three-layer structure including a surface layer, a core layer and an inner layer. The surface layer is prepared from the following raw materials comprising, by weight, 70-80 parts of an ethylene-propylene-butylene terpolymer, 12-15 parts of an ethylene-butylene copolymer, 5-7 parts of oxidized polyethlene wax, 13-17 parts of modified mesoporous silica and 3-4.5 parts of polytetrafluoroethylene modified polyethylene wax powder. The core layer is prepared from the following raw materials comprising, by weight, 75-85 parts of polypropylene, 12-16 parts of colorless transparent epoxy resin, 7-9 parts of a polymer of 2, 5-furandione, ethylene and 1-propylene, 4-6 parts of oxidized polypropylene wax and 3-4 parts of nano silicon dioxide. The multi-layer co-extrusion heat-sealing type polypropylene film has the advantages that the normal-temperature static / dynamic friction factor is small, and the high-temperature change is very small; the thermal shrinkage rate is low, and the stiffness is high; the wear resistance is excellent; the barrier property is excellent; and the comprehensive performance is good.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

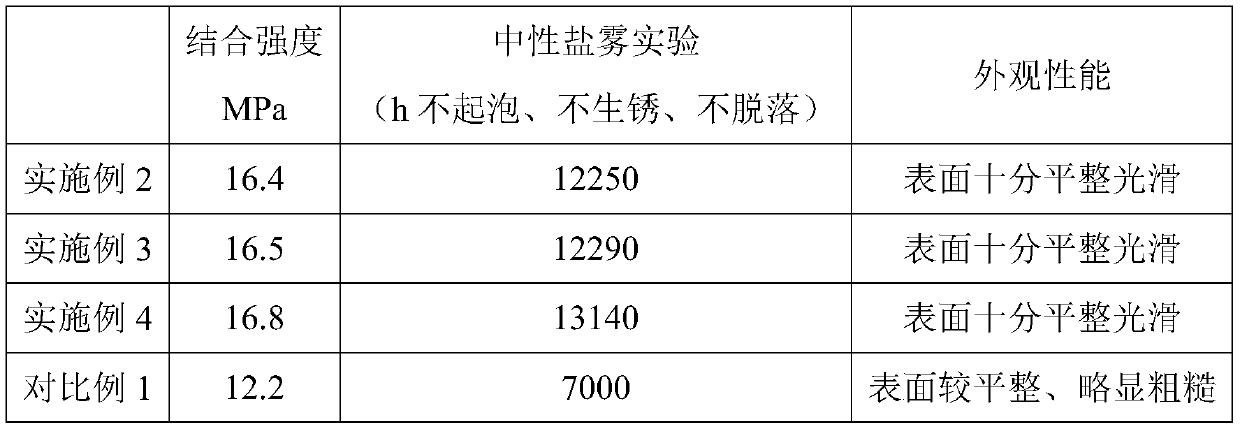

Rare earth alloy hot-dip coating steel plate and production method thereof

ActiveCN110777316AHigh tensile bond strengthImprove corrosion resistanceHot-dipping/immersion processesAlloyDip-coating

The invention discloses a rare earth alloy hot-dip coating steel plate and a production method thereof. The rare earth alloy hot-dip coating steel plate comprises a base steel plate and a rare earth alloy hot-dip coating; the rare earth alloy hot-dip coating covers the surface of the base steel plate; the rare earth alloy hot-dip coating comprises, by mass, 0.1-0.8% of magnesium, 0.05- 0.15% of aluminum, 0.002-0.090% of lanthanum and vanadium, 0.03-0.09% of nickel, 0.01-0.25% of bismuth, 0.05-0.13% of lead and the balance zinc and inevitable impurities; and the ratio of the mass of the lanthanum and the vanadium is 1: (0.42-0.48). According to the rare earth alloy hot-dip coating steel plate, the tensile bonding strength of the rare earth alloy hot-dip coating and the base steel plate is high; in the case of the same thickness of the coating, compared with a traditional pure zinc coating, the corrosion resistance of the rare earth alloy hot-dip coating steel plate is greatly improved to 175% or above; and the obtained coating surface is quite smooth.

Owner:JINJIANG ANNENG BUILDING MATERIALS MFG

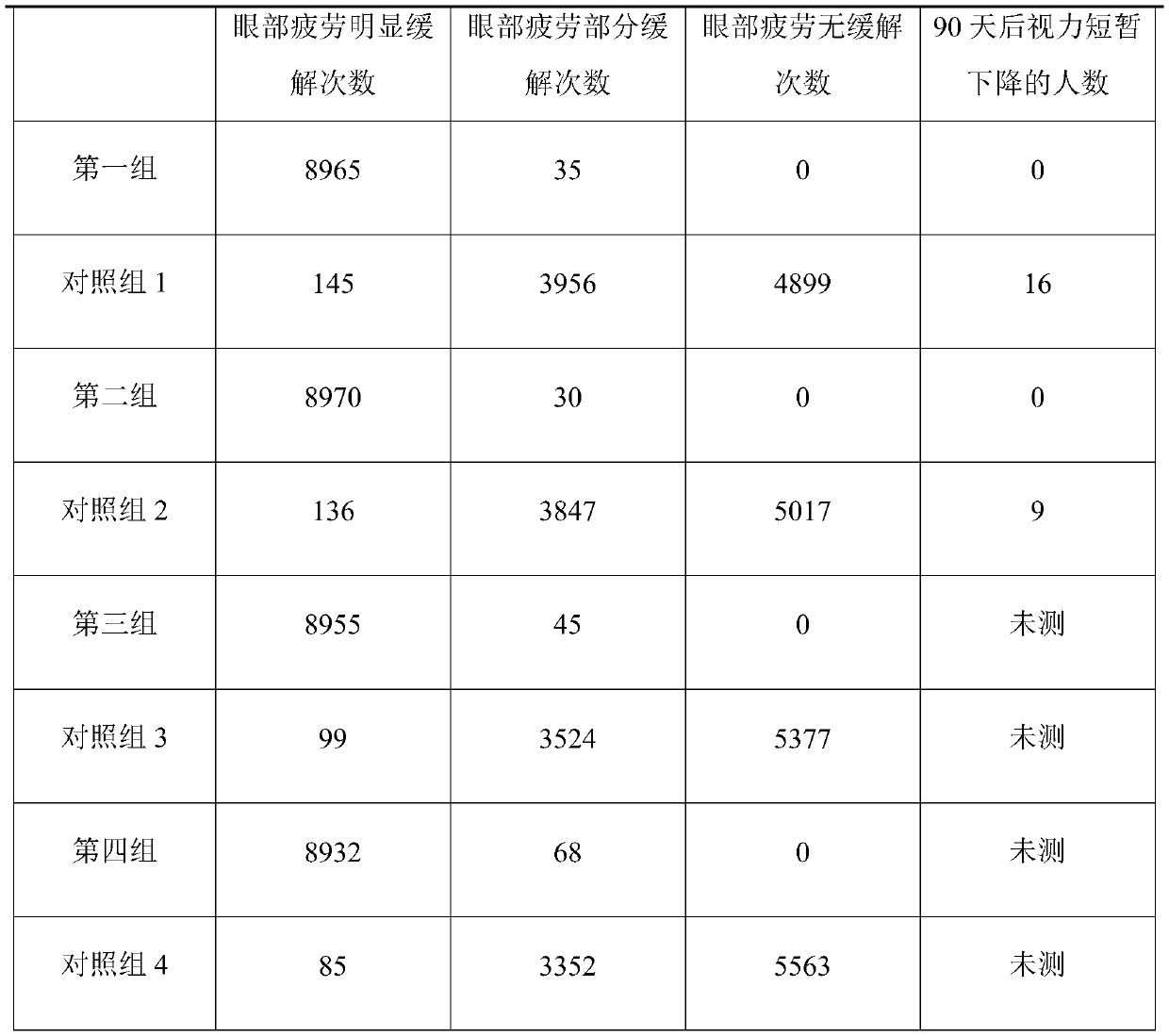

Moxa cone for relieving eye fatigue and preparation method thereof

InactiveCN110123898ASimple processSimple and efficient operationDevices for heating/cooling reflex pointsSenses disorderDrugEye Fatigue

The invention discloses a moxa cone for relieving eye fatigue, which is produced by the following raw materials in parts by weight: 8 to 12 parts of Chinese angelica, 10 to 14 parts of mulberry leaves, 9 to 11 parts of green tangerine peel, 15 to 17 parts of cassia seed, 7 to 10 parts of wild chrysanthemum and 290 to 310 parts of an Artemisia argyi extract. After screening and comparison, a systematic and complete research is carried out in accordance with national drug management requirements, the raw materials selected, and the content of each raw material is optimized, the Chinese angelica,mulberry leaf, green tangerine peel, cassia seed, wild chrysanthemum and the Artemisia argyi extract with the appropriate ratio are selected to prepare the moxa cone for relieving eye fatigue, through moxibustion therapy, the moxa cone has obvious effects on relieving eye fatigue and preventing myopia, and does not hurt the eyes, and has no toxic and side effects.

Owner:浙江乾一生物科技有限公司

Acidic copper plating additive and preparation method thereof

The invention discloses an acidic copper plating additive. The additive is prepared from, by weight, a main complex, an auxiliary complex, a surfactant and other additives, wherein the main complex isbis-(sodium sulfopropyl)-disulfide, the auxiliary complex is 2-mercaptobenzimidazol copper salt, the surfactant is a mixture of pesticide emulsifier 603 and 2-mercaptobenzimidazole, the molar ratio of pesticide emulsifier 603 to 2-mercaptobenzimidazole is 1:(0.35-0.45), and other additives are tolyltriazole. The acidic copper plating additive can greatly improve the coating adhesion of a copper-plated product, the corrosion resistance is remarkably improved, the glossiness is improved, and the surface is flat and bright.

Owner:浙江金欣新材料科技股份有限公司

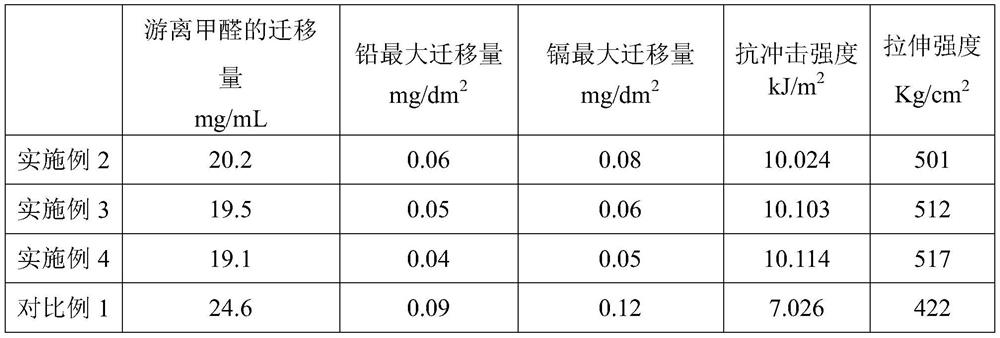

High-strength impact-resistant melamine resin tableware and preparation method thereof

The invention discloses high-strength impact-resistant melamine resin tableware and a preparation method thereof. The high-strength impact-resistant melamine resin tableware is prepared from the following raw materials in parts by weight: 60 to 75 parts of melamine-formaldehyde resin, 16 to 22 parts of ethylene-methyl methacrylate copolymer powder, 25 to 33 parts of an elastomer, 5 to 8 parts of cellulose, 1.5 to 2.5 parts of zinc peroxide, 3 to 5 parts of aluminum borate whiskers, 3 to 5 parts of nano silicon dioxide, 2.5 to 3.5 parts of zinc stearate, 1 to 2 parts of triethanolamine and 1.5 to 2 parts of methylmalonic acid. The high-strength impact-resistant melamine resin tableware is high in impact strength, high in tensile strength, excellent in mechanical property, resistant to impact (impact), not prone to damage and cracking and the like; the migration volume of free formaldehyde is low, and the maximum migration volume of lead and cadmium is also low and is lower than the migration volume of free formaldehyde and the maximum migration volume of lead and cadmium in a comparison file 1, so that the tableware is healthy, environment-friendly and non-toxic; and in addition, the thermal decomposition initial temperature reaches 145 DEG C or above, the thermal decomposition initial temperature is high, and the heat resistance is good.

Owner:晋江市旭佰日用品有限责任公司

A kind of degradable disposable plastic film and its manufacturing method

ActiveCN110228261BFast degradationHigh tensile strengthSynthetic resin layered productsCellulosePolymer science

The invention discloses a degradable disposable plastic film, which comprises a bottom layer and a surface layer; the bottom layer includes the following raw materials in parts by weight: 45-55 parts of polyethylene terephthalate, 25-32 parts of polyethylene, 15-20 parts of maleic anhydride grafted polyethylene, 5-9 parts of lignocellulose, 6-9 parts of hemp fiber, 3.4-4.5 parts of plasticizer, 16-22 parts of filler; the surface layer includes the following parts by weight Raw materials: 22-25 parts of polyethylene terephthalate, 50-55 parts of polyethylene, 14-17 parts of maleic anhydride grafted polyethylene, 10-15 parts of fluorinated plant fiber, 8-12 parts of starch, nano 5-7 parts of titanium dioxide, 3.5-4.8 parts of plasticizer, and 12-16 parts of filler. The degradable disposable plastic film of the present invention has the advantages of fast degradation speed, high tensile strength, large elongation at break, good mechanical properties, etc., is not easy to be damaged during use, and has good user experience.

Owner:福建冠翔日用塑料制品有限公司

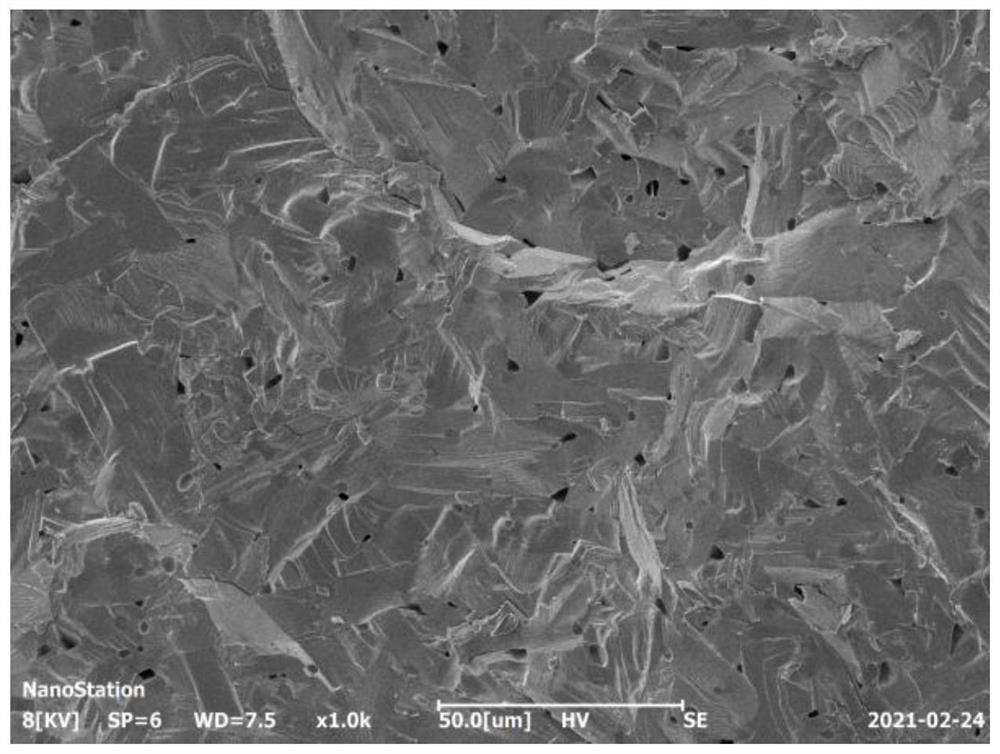

Tear-resistant and wear-resistant fabric and preparation method thereof

PendingCN114395842AImprove tear resistanceImprove wear resistanceWeft knittingWarp knittingFiberPolymer science

The invention discloses a tear-resistant and wear-resistant fabric and a preparation method thereof. The tear-resistant and wear-resistant fabric is prepared from high-performance composite fibers through a knitting or weaving process; the high-performance composite fiber comprises an inner layer and an outer layer; the outer layer covers the outer surface of the inner layer, and the section contour of the outer layer is circular; the ratio of the cross section area of the inner layer to the cross section area of the outer layer is 1: (0.55-0.65); the inner layer is prepared from the following raw materials in parts by weight: 75-85 parts of polyhexamethylene adipamide, 18-23 parts of organic silicon modified polyurethane elastomer and 6-9 parts of filler; the outer layer is prepared from the following raw materials in parts by weight: 55 to 65 parts of polyhexamethylene dodecanamide, 30 to 37 parts of polypentamethylene diamine adipate, 8 to 12 parts of phenylene ether silicone rubber, 2 to 2.5 parts of graphene fiber, 2.4 to 3 parts of glass fiber, 1.8 to 2.2 parts of nano silicon dioxide and 4 to 6 parts of oxidized polyethlene wax. The tear-resistant and wear-resistant fabric disclosed by the invention is excellent in tear resistance and wear resistance.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

A preparation method for multilayer piezoelectric ceramics used in a high temperature environment of 482°C

ActiveCN112939613BMeet the use requirementsExcellent piezoelectric propertiesThermal insulationSlurry

The invention discloses a method for preparing multilayer piezoelectric ceramics used in a high-temperature environment of 482°C, which mainly includes the following steps: stirring high-temperature ceramic powder, solvent, dispersant, binder and thickener with a stirrer Uniform preparation of casting slurry; forming a film of a certain thickness through a casting machine and printing the inner electrode, and printing the outer electrode after isostatic lamination; debinding at a low heating rate and sintering ceramics at low temperature; ceramic polarization and high temperature Aging stabilizes the piezoelectric properties. The multilayer piezoelectric ceramics prepared by the method for preparing multilayer piezoelectric ceramics used in a high-temperature environment of 482°C according to the present invention can meet the use requirements of a high-temperature environment, and have good piezoelectric performance, and can be completely used in a high-temperature environment of 482°C , The piezoelectric performance is stable after a long time of heat preservation at a high temperature of 482 ° C; the performance is stable after aging at a high temperature of 550 ° C, meeting the requirements of high temperature environments.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG +4

Universal electroplating additive and preparation method thereof

The invention discloses a universal electroplating additive. The universal electroplating additive is prepared from the following raw materials in parts by weight: sodium tartrate, sodium citrate, benzylidene acetone, 2-mercapto benzimidazole, 2-ethylhexyl sodium sulfate and allylthiourea. The universal electroplating additive disclosed by the invention can be suitable for various electroplating processes such as copper plating, zinc plating and copper-zinc alloy plating, and the flatness and glossiness of a surface plating layer of an electroplated product are greatly improved; and the corrosion resistance can be remarkably improved, the hardness of the plating layer is improved, and the current efficiency, the dispersion capacity and other properties of a plating solution are well improved.

Owner:浙江金欣新材料科技股份有限公司

A kind of diamond saw blade and preparation method thereof

ActiveCN109175388BHigh hardnessImprove impact toughnessMetal sawing tool makingMetal sawing toolsIron powderPolycrystalline diamond

The invention discloses a diamond saw blade and a preparation method thereof. The cutter head includes a first cutting area and a second cutting area; the first cutting area includes the following raw materials in parts by weight: 8-14 parts of polycrystalline diamond particles, iron powder 48-55 parts, copper powder 25-32 parts, zinc powder 4-6 parts, tin powder 2-3 parts, nickel powder 1.5-2.5 parts, cobalt powder 2-3 parts, manganese powder 1.5-2 parts, tungsten carbide and 2.5-5 parts of titanium carbide mixture powder, 0.4-0.7 part of lanthanum nickel five powder; the second cutting zone includes the following raw materials by weight: 10-16 parts of polycrystalline diamond and boron carbide mixture particles, 45-50 parts of iron powder, copper 27-33 parts of powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-4 parts of titanium carbide powder, lanthanum 0.4 to 0.7 parts of nickel five powder. The diamond saw blade of the invention has excellent comprehensive performance.

Owner:泉州市华兴超硬工具有限公司

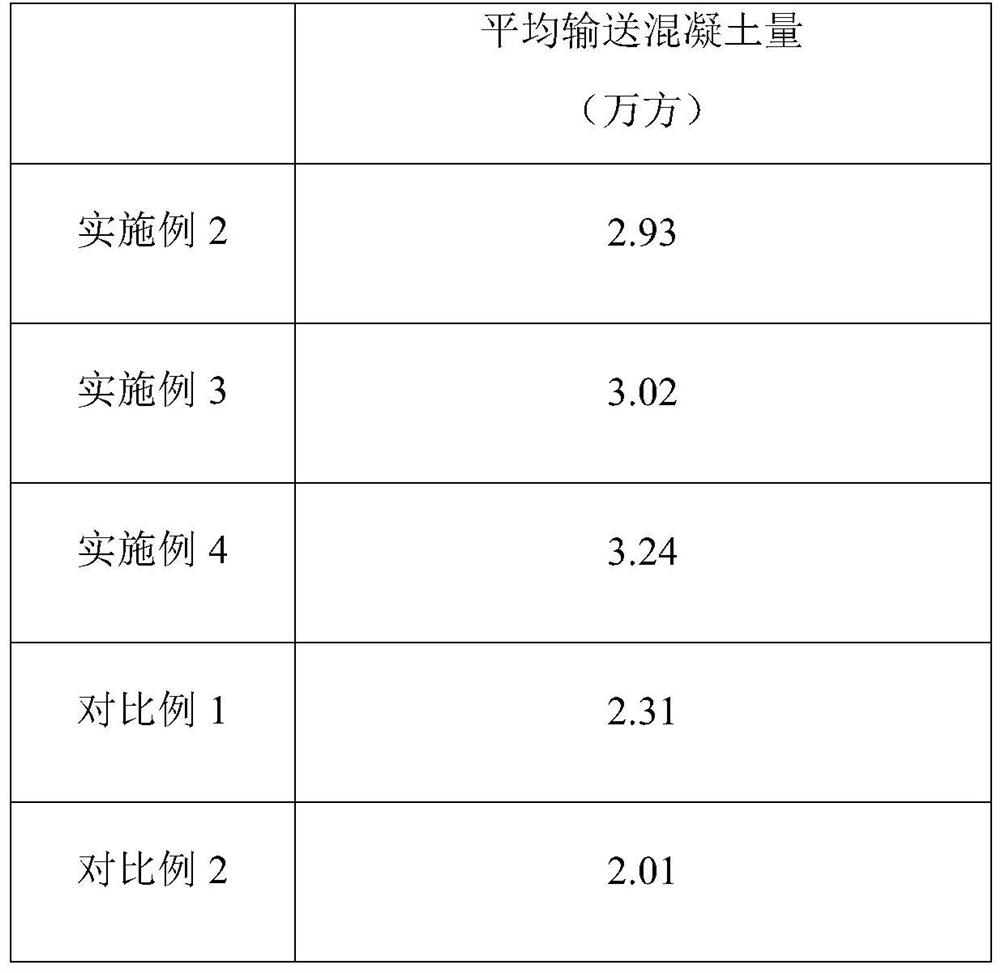

A high-performance concrete piston seal material and its preparation process

The invention discloses a high-performance concrete piston sealing material, which is made of the following raw materials in parts by weight: 15-19 parts of 2,4-diphenylmethane diisocyanate, 35-45 parts of polyether type isocyanate prepolymer 16-24 parts of polytetramethylene ether glycol, 14-18 parts of polyoxyethylene polyol, 15-19 parts of ethylene glycol and benzenetriol mixture, 2.5-3.5 parts of antioxidant, 3-5 parts of filler ; The mass ratio of ethylene glycol and benzenetriol in the mixture of ethylene glycol and benzenetriol is 1:0.35-0.5. The hydrolysis resistance, wear resistance, rebound performance, dynamic fatigue performance, etc. of the high-performance concrete piston seal of the present invention have been greatly improved. Under the same working conditions, the service life of the high-performance concrete piston seal of the present invention It is more than 1.5 times that of the existing products. The high-performance concrete piston seal of the present invention not only has excellent performance, but also has good consistency and stability in product quality.

Owner:唯万科技有限公司

A kind of warm and antibacterial school uniform fabric and preparation method thereof

ActiveCN112048817BHigh antibacterial rateGood antibacterial effectGarment special featuresWeft knittingFiberPolyurethane elastomer

The invention discloses a warm-keeping and antibacterial school uniform fabric and a preparation method thereof. The warm-keeping and antibacterial school uniform fabric is prepared from a warm-keeping and antibacterial composite fiber through a knitting or weaving process; the warm-keeping and antibacterial composite fiber includes an inner layer and an outer layer. layer; the outer layer is coated on the outer surface of the inner layer, and the cross-sectional profile of the outer layer is circular; the ratio of the cross-sectional area of the inner layer to the outer layer is 1:1.35 to 1.55; the The inner layer is made of the following raw materials in parts by weight: polyhexamethylene adipamide: 88-98 parts, polyurethane elastomer: 5-9 parts. The special warm-keeping and antibacterial composite fiber adopted in the warm-keeping and antibacterial school uniform fabric of the present invention has an inner layer and an outer layer structure, has a high antibacterial rate, and has a good antibacterial effect. Good performance, good resilience, soft hand feeling, comfortable to wear; good moisture absorption and perspiration performance, high tensile strength, good mechanical properties; suitable as school uniform fabric.

Owner:润克(集团)股份有限公司

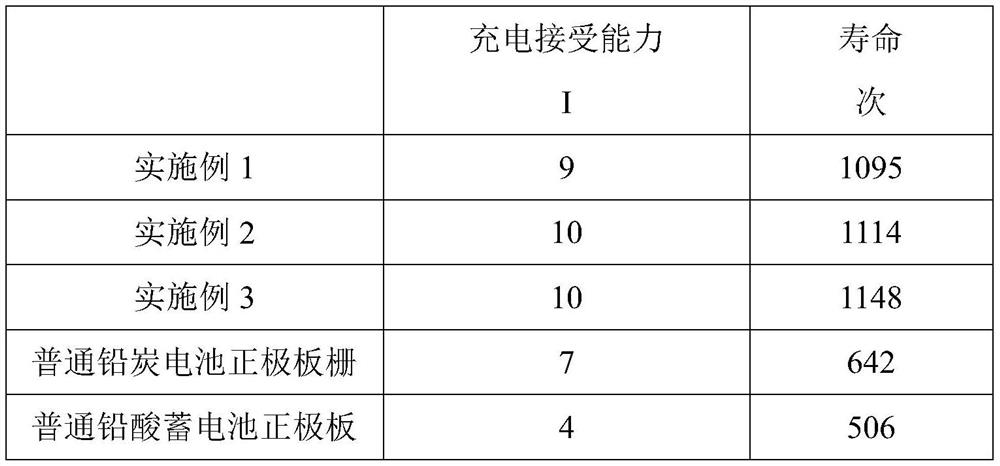

A kind of positive electrode grid of graphene lead-carbon battery and preparation method thereof

ActiveCN112614980BStrong charge acceptanceExtended service lifeMaterial nanotechnologyElectrode carriers/collectorsCarbon fibersDioxyethylene Ether

The invention discloses a graphene lead-carbon battery positive electrode grid and a preparation method thereof. The graphene lead-carbon battery positive electrode grid includes a lead grid blank and graphene lead paste covering the surface of the lead grid blank; The graphene lead paste is made of raw materials including the following parts by weight: 750-820 parts of sponge lead, 10-14 parts of barium sulfate, 1.4-1.8 parts of graphene, 0.75-0.85 parts of polyacrylonitrile-based carbon fiber, carboxylated carbon 0.9-1.2 parts of nanotubes, 60-90 parts of water-based polyurethane, 0.7-0.9 parts of isocyanate, 80-95 parts of dodecyl alcohol, 40-50 parts of isoprene glycol, and 0.2-0.3 parts of polyoxyethylene lauryl ether. The positive electrode grid of the graphene lead-carbon battery of the present invention has strong charging acceptance ability and long service life, and is superior to the positive electrode grid of the common lead-carbon battery and obviously superior to the positive plate of the common lead-acid storage battery.

Owner:QUANZHOU KAIYING POWER SUPPLY ELECTRICAL APPLIANCES

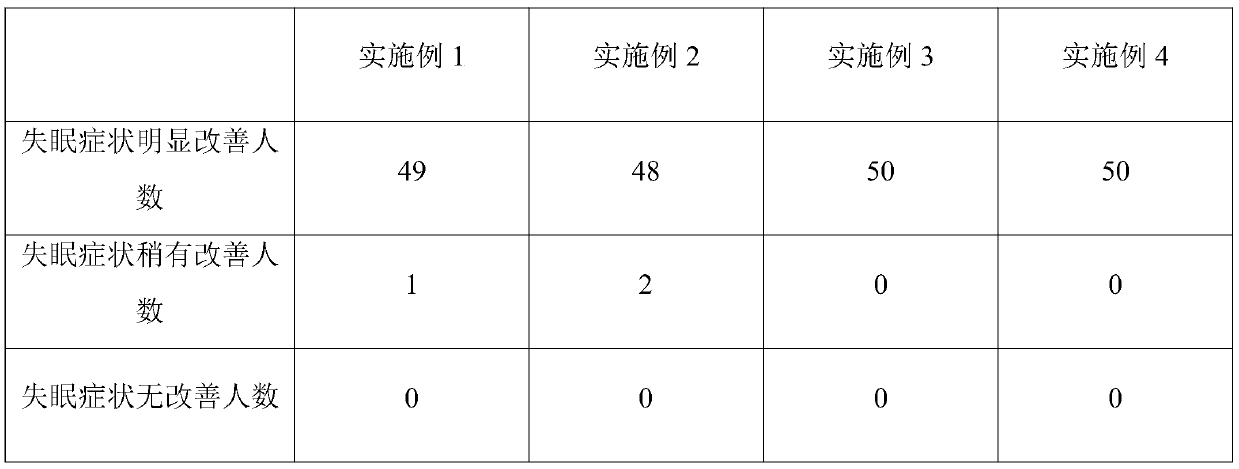

Formula of foot soaking herb bag and preparation method of herb bag with same

InactiveCN110101824ASimple processSimple and fast operationNervous disorderInanimate material medical ingredientsCodonopsis pilosulaTwig

The invention discloses a formula of a foot soaking herb bag. The formula comprises, by weight, 95-100 parts of folium artemisiae argyi, 0.8-1.2 parts of radix bupleuri, 1.8-2.2 parts of scutellaria baicalensis, 0.9-1.2 parts of pinellia ternata, 0.8-1.1 parts of codonopsis pilosula, 1.3-1.6 parts of poria cocos, 3-4 parts of calcined keel, 2.8-3.4 parts of calcined oyster, 2.5-3.2 parts of nacremother of pearl, 3.5-4.3 parts of cassia twig, 2-2.5 parts of radix curcumae, 2.5-3 parts of polygala root, 3.6-4.4 parts of rhizoma cyperi, 1.2-1.6 parts of radix rehmanniae and 8-13 parts of clove.By adopting the formula of the foot soaking her bag, the prepared foot soaking herb bag can improve sleep, has the effects of warming uterus, expelling wind coldness, preventing cold, promoting bloodcirculation, nourishing blood, expelling toxin, beautifying skin and the like, does not hurt the body and has no toxic or side effect.

Owner:浙江乾一生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com