Tear-resistant and wear-resistant fabric and preparation method thereof

A wear-resistant fabric and tear-resistant technology, applied in the field of textile fabrics, can solve the problems of poor tear resistance, poor wear resistance, and short service life, achieve excellent tear resistance and wear resistance, and improve tensile strength. Strength and elongation at break, the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

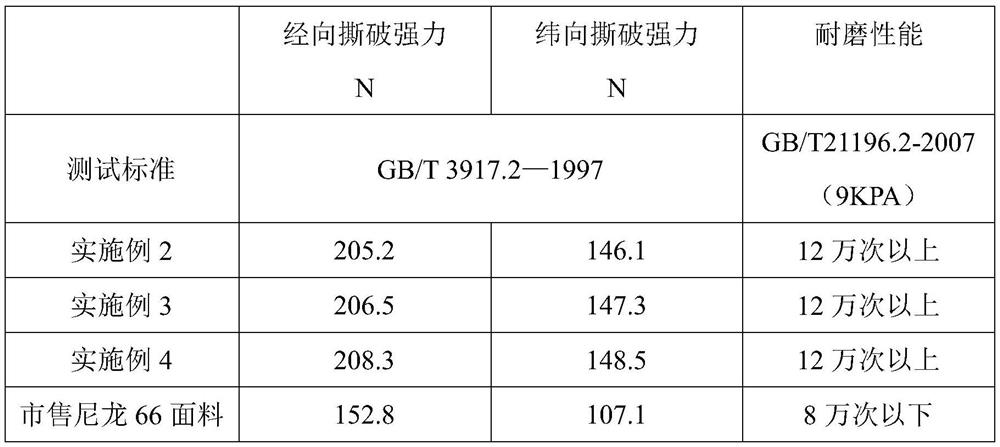

Examples

Embodiment 1

[0046] A tear-resistant and wear-resistant fabric, the tear-resistant wear-resistant fabric is made of high-performance composite fibers through knitting or weaving;

[0047] The high-performance composite fiber includes an inner layer and an outer layer;

[0048] The outer layer is coated on the outer surface of the inner layer, and the cross-sectional profile of the outer layer is circular;

[0049] The ratio of the cross-sectional area of the inner layer to the outer layer is 1: (0.55-0.65);

[0050]The inner layer is made of the following raw materials in parts by weight: 75-85 parts of polyhexamethylene adipamide, 18-23 parts of silicone-modified polyurethane elastomer, and 6-9 parts of filler;

[0051] The outer layer is made of the following raw materials in parts by weight: 55-65 parts of polyhexamethylene diamide, 30-37 parts of polypentamethylene adipate, 8-12 parts of phenylene ether silicone rubber, graphite 2-2.5 parts of vinyl fiber, 2.4-3 parts of glass fibe...

Embodiment 2

[0066] A tear-resistant and wear-resistant fabric, the tear-resistant wear-resistant fabric is made of high-performance composite fibers through knitting or weaving;

[0067] The high-performance composite fiber includes an inner layer and an outer layer;

[0068] The outer layer is coated on the outer surface of the inner layer, and the cross-sectional profile of the outer layer is circular;

[0069] The ratio of the cross-sectional area of the inner layer to the outer layer is 1:0.55;

[0070] The inner layer is made of the following raw materials in parts by weight: 75 parts of polyhexamethylene adipamide, 18 parts of silicone-modified polyurethane elastomer, and 6 parts of filler;

[0071] The outer layer is made of the following raw materials in parts by weight: 55 parts of polyhexamethylene diamide, 30 parts of polypentamethylene adipate, 8 parts of phenylene oxide silicone rubber, 2 parts of graphene fiber, glass 2.4 parts of fiber, 1.8 parts of nano silicon dioxide...

Embodiment 3

[0083] A tear-resistant and wear-resistant fabric, the tear-resistant wear-resistant fabric is made of high-performance composite fibers through knitting or weaving;

[0084] The high-performance composite fiber includes an inner layer and an outer layer;

[0085] The outer layer is coated on the outer surface of the inner layer, and the cross-sectional profile of the outer layer is circular;

[0086] The ratio of the cross-sectional area of the inner layer to the outer layer is 1:0.65;

[0087] The inner layer is made of the following raw materials in parts by weight: 85 parts of polyhexamethylene adipamide, 23 parts of silicone-modified polyurethane elastomer, and 9 parts of filler;

[0088] The outer layer is made of raw materials including the following parts by weight: 65 parts of polyhexamethylene diamide, 37 parts of polypentamethylene adipate, 12 parts of phenylene oxide silicone rubber, 2.5 parts of graphene fiber, glass 3 parts of fiber, 2.2 parts of nano silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com