Degradable disposable plastic film and preparation method thereof

A plastic film, disposable technology, applied in the field of plastic film products, can solve the problem of poor mechanical properties such as tensile strength, elongation at break, puncture resistance, etc. , can not be vigorously promoted and used, etc., to achieve the effect of improving the sameness, good heat resistance, and optimizing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A degradable single-use plastic film comprising a base layer and a top layer;

[0039] The bottom layer is made of the following raw materials in parts by weight: 45-55 parts of polyethylene terephthalate, 25-32 parts of polyethylene, 15-20 parts of maleic anhydride grafted polyethylene, 5-5 parts of lignocellulose 9 parts, 6-9 parts of hemp fiber, 3.4-4.5 parts of plasticizer, 16-22 parts of filler;

[0040] The surface layer is made of the following raw materials in parts by weight: 22-25 parts of polyethylene terephthalate, 50-55 parts of polyethylene, 14-17 parts of maleic anhydride grafted polyethylene, fluorinated plant fiber 10-15 parts, 8-12 parts of starch, 5-7 parts of nano titanium dioxide, 3.5-4.8 parts of plasticizer, 12-16 parts of filler.

[0041] Preferably, the bottom layer is made of raw materials including the following parts by weight: 50 parts of polyethylene terephthalate, 28.5 parts of polyethylene, 17.8 parts of maleic anhydride grafted polyethy...

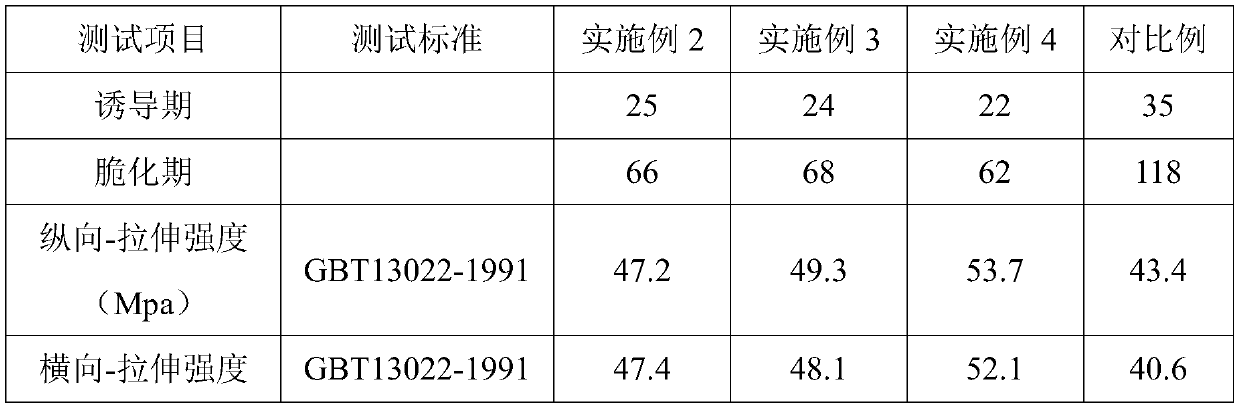

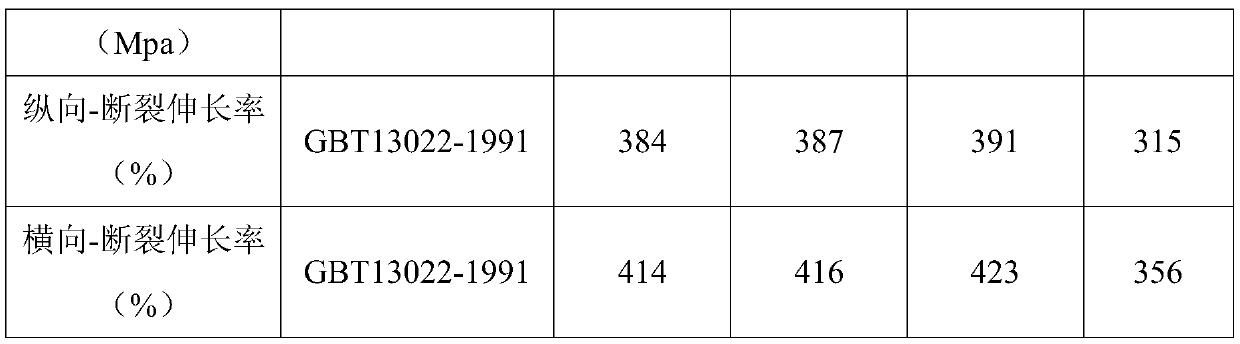

Embodiment 2

[0054] A degradable single-use plastic film comprising a base layer and a top layer;

[0055] The bottom layer is made of raw materials including the following parts by weight: 45 parts of polyethylene terephthalate, 25 parts of polyethylene, 15 parts of maleic anhydride grafted polyethylene, 5 parts of lignocellulose, 6 parts of hemp fiber, 3.4 parts of plasticizer, 16 parts of filler;

[0056] The surface layer is made of the following raw materials in parts by weight: 22 parts of polyethylene terephthalate, 50 parts of polyethylene, 14 parts of maleic anhydride grafted polyethylene, 10 parts of fluorinated plant fiber, and 8 parts of starch , 5 parts of nano-titanium dioxide, 3.5 parts of plasticizer, and 12 parts of filler.

[0057] In this embodiment, the raw materials of the bottom layer and the surface layer also include 2.5 parts of maleic anhydride grafted polyethylene wax.

[0058] In this embodiment, the plasticizer is tributyl citrate.

[0059] In this embodimen...

Embodiment 3

[0066] A degradable single-use plastic film comprising a base layer and a top layer;

[0067] The bottom layer is made of the following raw materials by weight: 55 parts of polyethylene terephthalate, 32 parts of polyethylene, 20 parts of maleic anhydride grafted polyethylene, 9 parts of lignocellulose, 9 parts of hemp fiber, 4.5 parts of plasticizer, 22 parts of filler;

[0068] The surface layer is made of the following raw materials in parts by weight: 25 parts of polyethylene terephthalate, 55 parts of polyethylene, 17 parts of maleic anhydride grafted polyethylene, 15 parts of fluorinated plant fiber, and 12 parts of starch , 7 parts of nano-titanium dioxide, 4.8 parts of plasticizer, and 16 parts of filler.

[0069] In this embodiment, the raw materials of the bottom layer and the surface layer also include 4.5 parts of maleic anhydride grafted polyethylene wax.

[0070] In this embodiment, the plasticizer is tributyl citrate.

[0071] In this embodiment, the filler i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com