A high-performance concrete piston seal material and its preparation process

A technology for concrete pistons and seals, which is applied in the field of high-performance concrete piston seal materials and preparation technology, and can solve the problems of short service life of concrete piston seals, short service life of concrete pistons, hydrolysis resistance, low temperature resistance and resilience Performance, compressive performance, dynamic fatigue performance, and poor comprehensive performance such as anti-friction performance, etc., to achieve the effects of improving service life, improving hydrolysis resistance, good consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

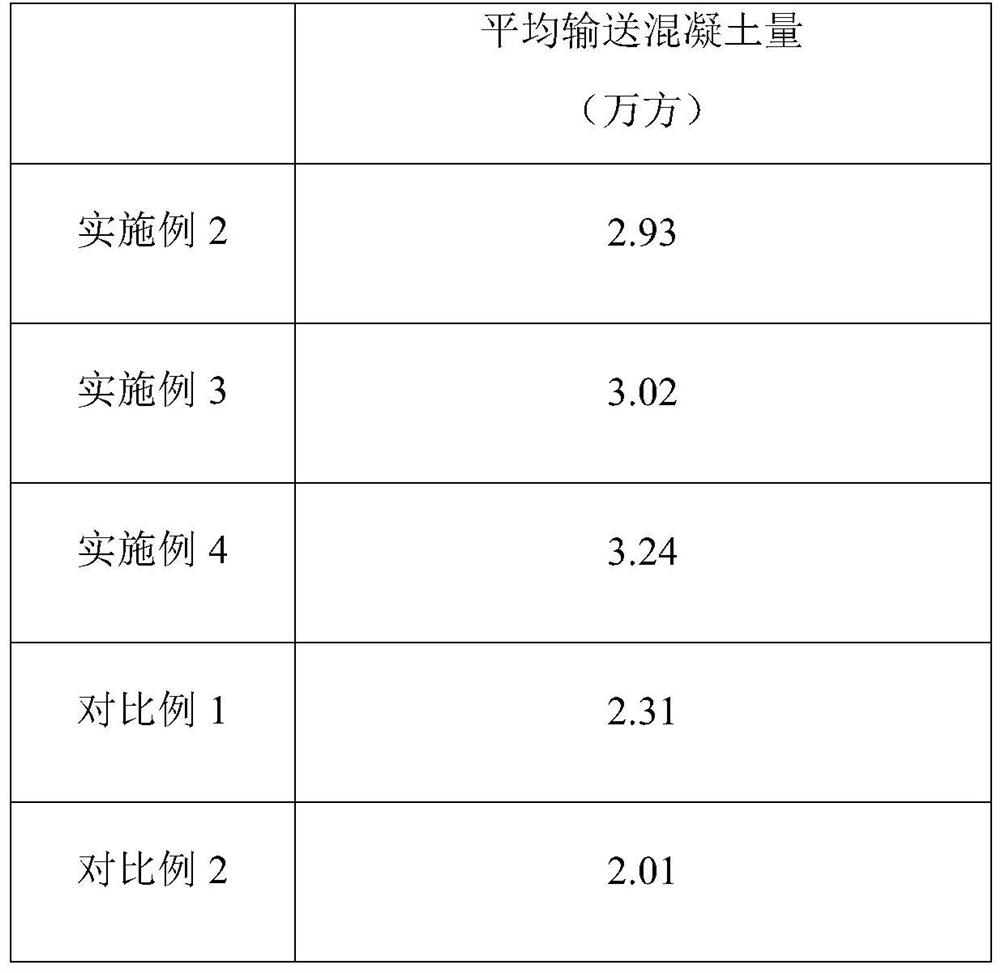

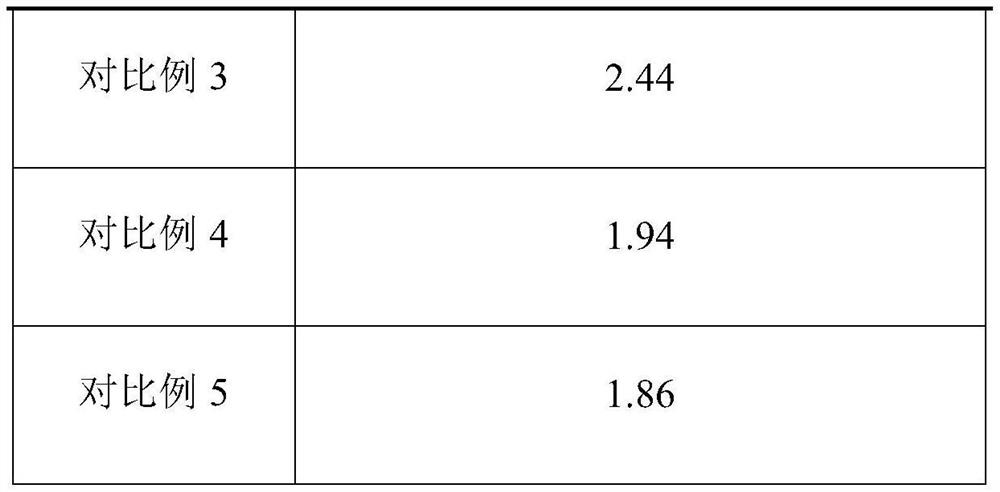

Examples

Embodiment 1

[0039] A high-performance concrete piston sealing material, which is made of the following raw materials in parts by weight: 15-19 parts of 2,4-diphenylmethane diisocyanate, 35-45 parts of polyether-type isocyanate prepolymer, polytetrafluoroethylene 16-24 parts of methylene ether glycol, 14-18 parts of polyoxyethylene polyol, 15-19 parts of ethylene glycol and benzenetriol mixture, 2.5-3.5 parts of antioxidant, 3-5 parts of filler; The mass ratio of ethylene glycol and benzenetriol in the mixture of diol and benzenetriol is 1:0.35-0.5.

[0040] Preferably, the high-performance concrete piston seal material is made of the following raw materials in parts by weight: 17 parts of 2,4-diphenylmethane diisocyanate, 41.5 parts of polyether type isocyanate prepolymer, polytetramethylene 19.5 parts of base ether diols, 16.7 parts of polyoxyethylene polyols, 17.5 parts of ethylene glycol and benzenetriol mixtures, 3.1 parts of antioxidants, 4.6 parts of fillers; The mass ratio of alcoho...

Embodiment 2

[0059] A high-performance concrete piston sealing material, which is made of the following raw materials in parts by weight: 15 parts of 2,4-diphenylmethane diisocyanate, 35 parts of polyether type isocyanate prepolymer, polytetramethylene ether 16 parts of glycols, 14 parts of polyoxyethylene polyols, 15 parts of ethylene glycol and benzenetriol mixtures, 2.5 parts of antioxidants, 3 parts of fillers; The mass ratio is 1:0.35.

[0060] In this embodiment, the polyether type isocyanate prepolymer includes the following raw materials in parts by weight: 35 parts of 2,4-diphenylmethane diisocyanate, 55 parts of polyoxyethylene polyol with a number average molecular weight of 1500, 3 parts of tripropylene glycol diacrylate.

[0061] In the present embodiment, the preparation method of the polyether type isocyanate prepolymer is as follows:

[0062] Add polyoxyethylene polyol and tripropylene glycol diacrylate into the reaction kettle, use 2000rpm high-speed stirring and vacuumi...

Embodiment 3

[0078] A high-performance concrete piston sealing material, which is made of the following raw materials in parts by weight: 19 parts of 2,4-diphenylmethane diisocyanate, 45 parts of polyether type isocyanate prepolymer, polytetramethylene ether 24 parts of glycols, 18 parts of polyoxyethylene polyols, 19 parts of ethylene glycol and benzenetriol mixtures, 3.5 parts of antioxidants, 5 parts of fillers; The mass ratio is 1:0.5.

[0079] In this embodiment, the polyether type isocyanate prepolymer includes the following raw materials in parts by weight: 45 parts of 2,4-diphenylmethane diisocyanate, 65 parts of polyoxyethylene polyol with a number average molecular weight of 3000, 5 parts of tripropylene glycol diacrylate.

[0080] In the present embodiment, the preparation method of the polyether type isocyanate prepolymer is as follows:

[0081] Add polyoxyethylene polyol and tripropylene glycol diacrylate into the reaction kettle, stir at a high speed of 3000rpm and vacuumiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com