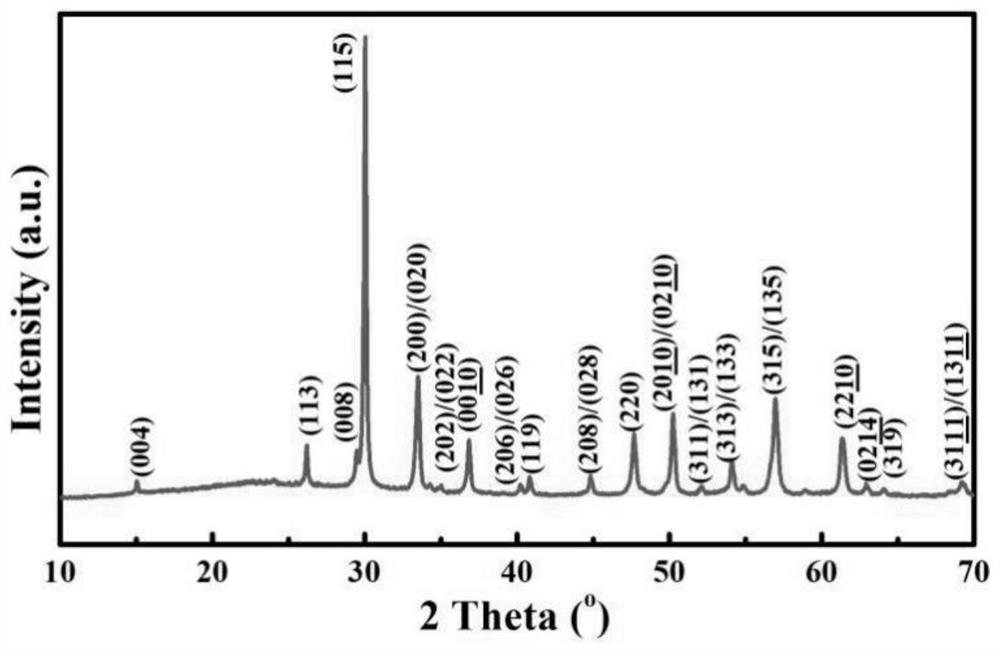

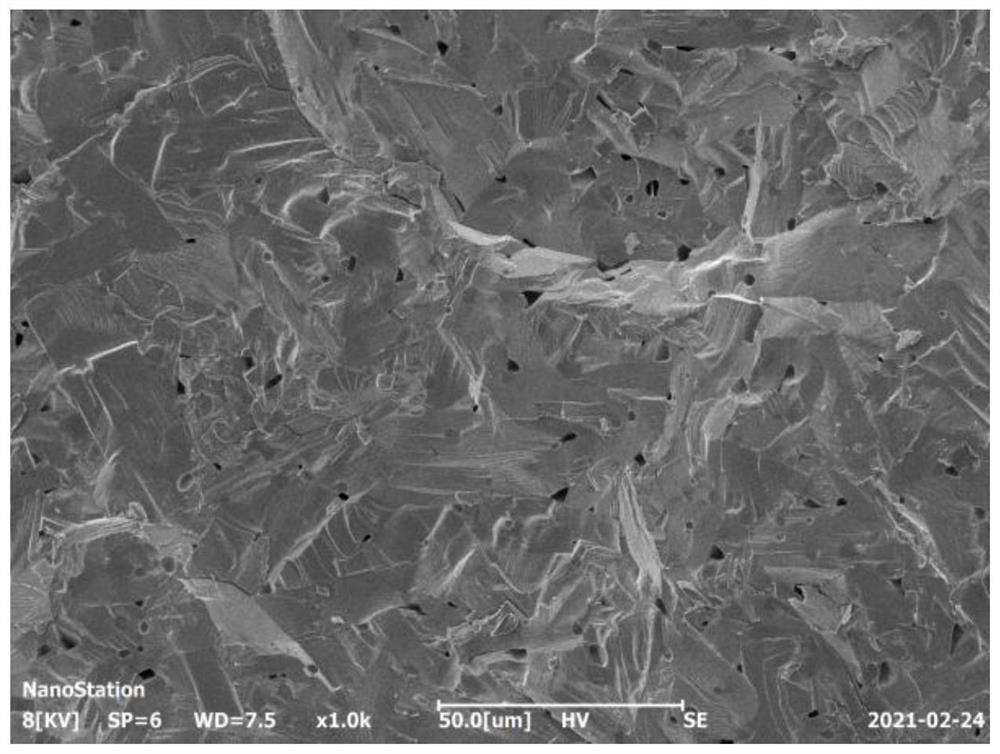

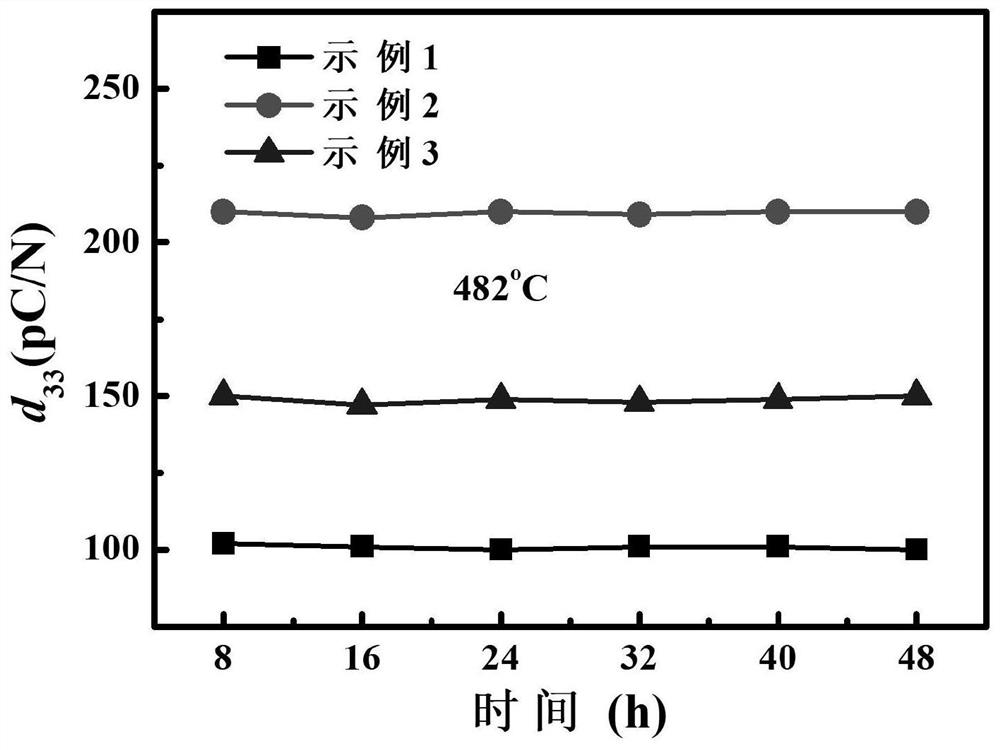

A preparation method for multilayer piezoelectric ceramics used in a high temperature environment of 482°C

A piezoelectric ceramics, high temperature environment technology, applied in the field of lead-free piezoelectric ceramics, can solve the problem of safe use temperature difficult to reach high temperature environment, etc., achieve the effect of stable piezoelectric performance, stable performance, and meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] S3, degreasing and sintering: degreasing and sintering the above-mentioned laminated diaphragms.

[0035] S4, polarization and aging: the sintered piezoelectric element is placed in an oil bath of 140-160 ° C, a voltage of 400-800V

[0037] In the S1, the particle size of the high-temperature piezoelectric powder is approximately normal distribution, and D50 is 0.1-0.2 μm.

[0043] In the S3, the sintering temperature is 850-1000 ° C.

[0046] The above slurry is formed into a film with a thickness of about 100 μm on a casting machine to print the film by screen printing.

[0048] The ceramic element was polarized for 30 min in an oil bath at 150°C and at a voltage of 600V, and then kept at 550°C after the polarization was completed.

[0052] Implementation Column 2

[0055] The above-mentioned device was heated to 600 °C at a heating rate of 1 °C / min to exclude organic matter, and then sintered at 1000 °C to obtain a

[0056] The ceramic element was polarized for 30 min in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com