A kind of degradable disposable plastic film and its manufacturing method

A plastic film, disposable technology, applied in the field of plastic film products, can solve the problem of poor mechanical properties such as tensile strength, elongation at break and puncture resistance, and poor mechanical properties such as tensile strength and elongation at break , can not be vigorously promoted and used, etc., to achieve the effect of improving the sameness, good heat resistance, and optimizing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

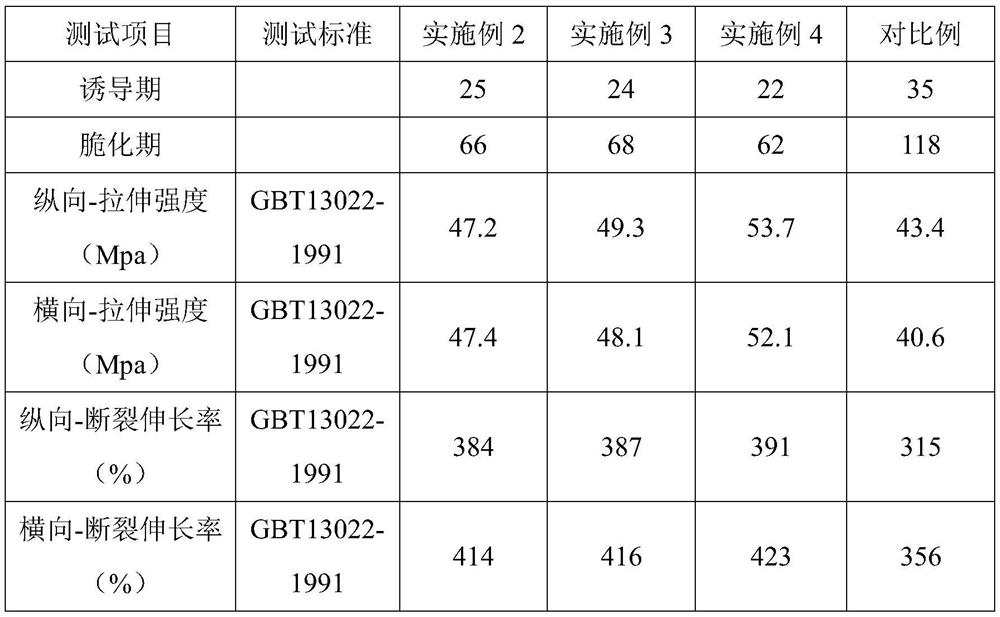

Examples

Embodiment 1

[0038] A degradable single-use plastic film comprising a base layer and a top layer;

[0039] The bottom layer includes the following raw materials in parts by weight: 45-55 parts of polyethylene terephthalate, 25-32 parts of polyethylene, 15-20 parts of maleic anhydride grafted polyethylene, 5-9 parts of lignocellulose, 6-9 parts of hemp fiber, 3.4-4.5 parts of plasticizer, 16-22 parts of filler;

[0040] The surface layer includes the following raw materials in parts by weight: 22-25 parts of polyethylene terephthalate, 50-55 parts of polyethylene, 14-17 parts of maleic anhydride grafted polyethylene, 10-15 parts of fluorinated plant fiber 8-12 parts of starch, 5-7 parts of nano-titanium dioxide, 3.5-4.8 parts of plasticizer, and 12-16 parts of filler.

[0041] Preferably, the bottom layer includes the following raw materials in parts by weight: 50 parts of polyethylene terephthalate, 28.5 parts of polyethylene, 17.8 parts of maleic anhydride grafted polyethylene, 7.7 parts...

Embodiment 2

[0054] A degradable single-use plastic film comprising a base layer and a top layer;

[0055] The bottom layer includes the following raw materials in parts by weight: 45 parts of polyethylene terephthalate, 25 parts of polyethylene, 15 parts of maleic anhydride grafted polyethylene, 5 parts of lignocellulose, 6 parts of hemp fiber, plasticizer 3.4 parts, 16 parts of filler;

[0056] The surface layer includes the following raw materials in parts by weight: 22 parts of polyethylene terephthalate, 50 parts of polyethylene, 14 parts of maleic anhydride grafted polyethylene, 10 parts of fluorinated plant fiber, 8 parts of starch, nano titanium dioxide 5 parts, plasticizer 3.5 parts, filler 12 parts.

[0057] In this embodiment, the raw materials of the bottom layer and the surface layer also include 2.5 parts of maleic anhydride grafted polyethylene wax.

[0058] In this embodiment, the plasticizer is tributyl citrate.

[0059] In this embodiment, the filler is calcium carbona...

Embodiment 3

[0066] A degradable single-use plastic film comprising a base layer and a top layer;

[0067] The bottom layer includes the following raw materials in parts by weight: 55 parts of polyethylene terephthalate, 32 parts of polyethylene, 20 parts of maleic anhydride grafted polyethylene, 9 parts of lignocellulose, 9 parts of hemp fiber, plasticizer 4.5 parts, 22 parts of filler;

[0068] The surface layer includes the following raw materials in parts by weight: 25 parts of polyethylene terephthalate, 55 parts of polyethylene, 17 parts of maleic anhydride grafted polyethylene, 15 parts of fluorinated plant fiber, 12 parts of starch, nano titanium dioxide 7 parts, 4.8 parts of plasticizer, 16 parts of filler.

[0069] In this embodiment, the raw materials of the bottom layer and the surface layer also include 4.5 parts of maleic anhydride grafted polyethylene wax.

[0070] In this embodiment, the plasticizer is tributyl citrate.

[0071] In this embodiment, the filler is calcium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com