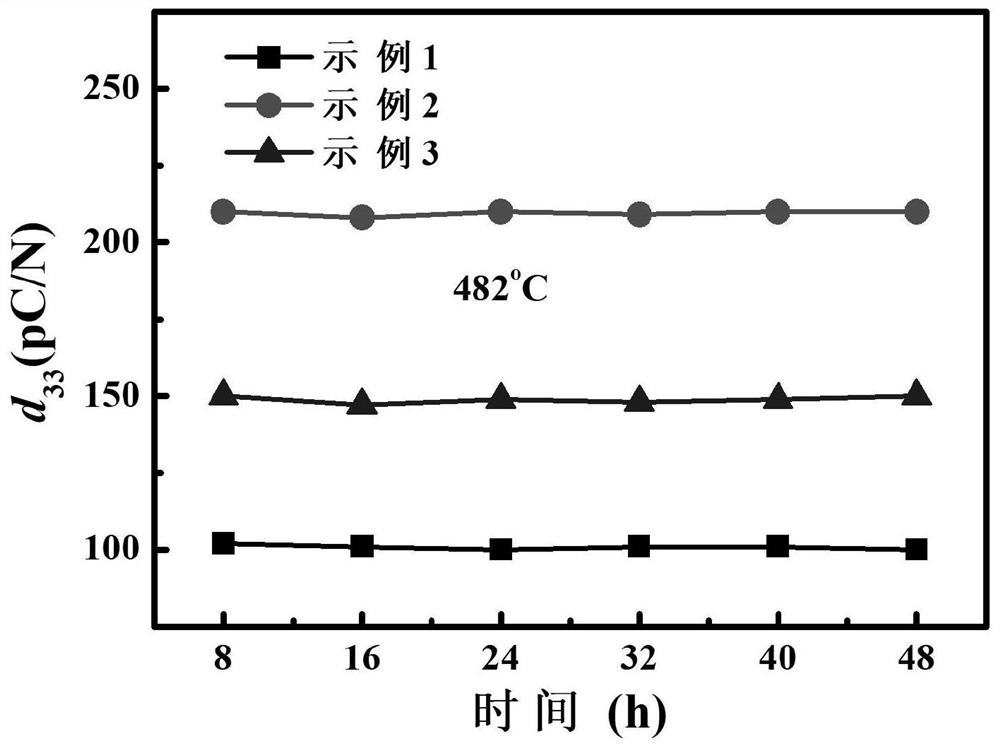

Preparation method of multilayer piezoelectric ceramic used in high-temperature environment of 482 DEG C

A technology of piezoelectric ceramics and high-temperature environment, which is applied in the field of lead-free piezoelectric ceramics, can solve the problem that the safe use temperature is difficult to reach high-temperature environments, and achieve stable piezoelectric performance, meet the use requirements, and good piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the preferred embodiments of the present invention will be described below in conjunction with specific examples, but this should not be construed as a limitation of this patent.

[0030] The test methods or test methods described in the following examples, unless otherwise specified, are conventional methods; the reagents and materials, unless otherwise specified, are obtained from conventional commercial channels or prepared by conventional methods.

[0031] A method for preparing a multilayer piezoelectric ceramic used in a high temperature environment of 482°C, characterized in that it comprises the following steps:

[0032] S1. Slurry preparation: Stir the high-temperature ceramic powder, solvent and dispersant with a stirrer at a low speed (200-500r / min) for 8-12 hours. After the stirring is completed, add a binder and a thickener and mix evenly with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com