Multi-layer co-extrusion heat-sealing type polypropylene film and preparation method thereof

A polypropylene film and multi-layer co-extrusion technology, which is applied in the field of multi-layer co-extrusion heat-sealing polypropylene film and its preparation, can solve the problems of poor gloss, haze, mechanical properties of heat-sealing strength, etc. The problem of increased dynamic friction factor and high static/dynamic friction factor can achieve the effect of not easy to whiten, prevent water vapor from passing through, and smooth packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

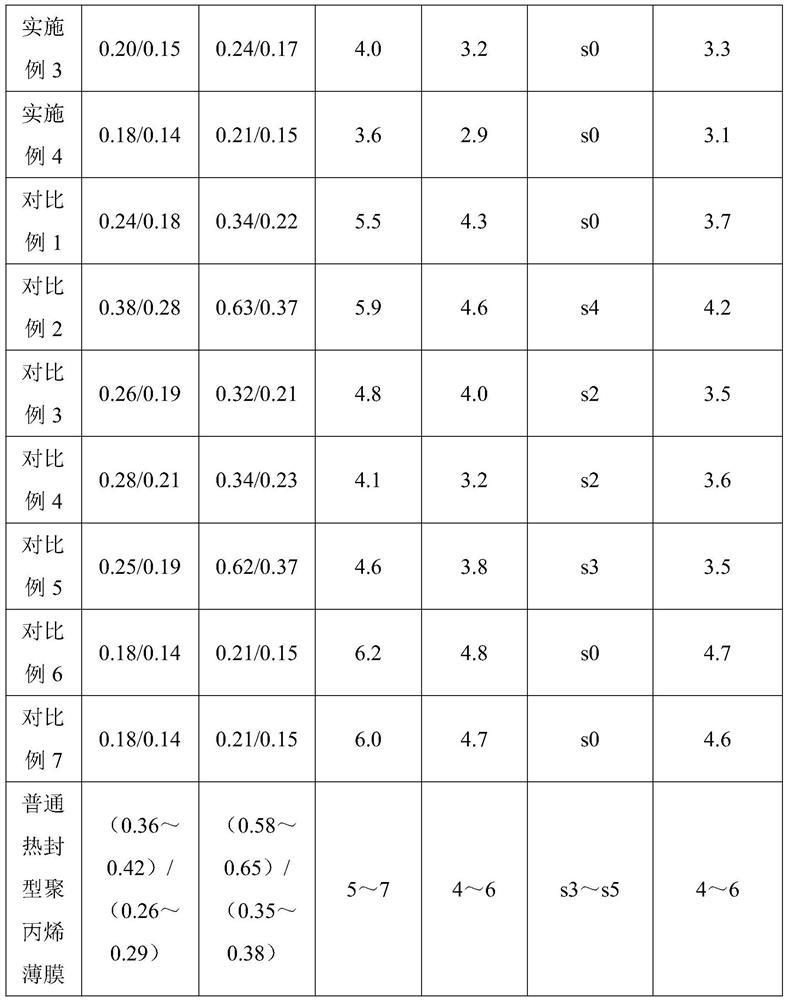

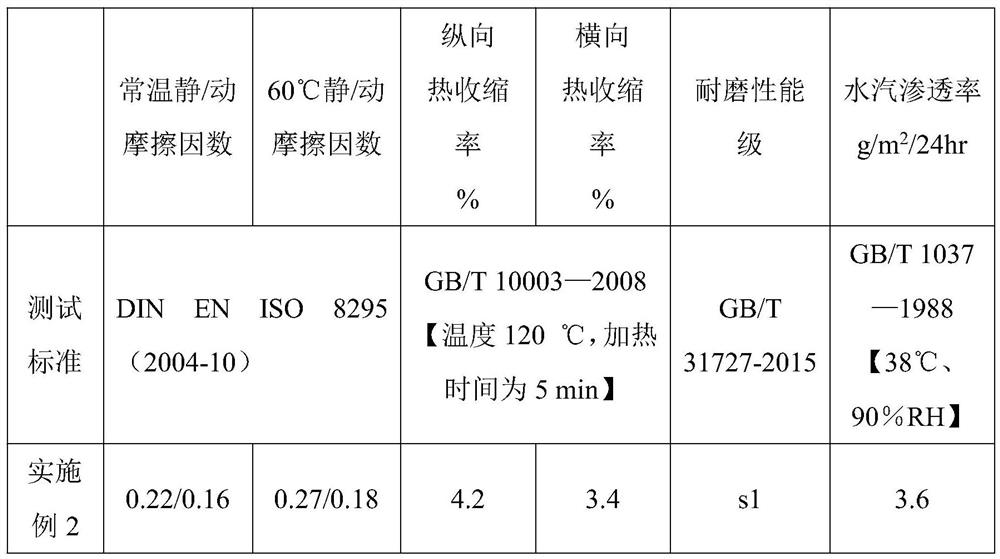

Examples

Embodiment 1

[0116] A multi-layer co-extruded heat-sealable polypropylene film, said multi-layer co-extruded heat-sealed polypropylene film is directly co-extruded from a surface layer, a core layer, and an inner layer three-layer structure;

[0117] Wherein, the surface layer is made of raw materials comprising the following parts by weight:

[0118] 70-80 parts of ethylene-propylene-butene terpolymer,

[0119] 12-15 parts of ethylene-butene copolymer,

[0120] 5-7 parts of oxidized polyethylene wax,

[0121] 13-17 parts of modified mesoporous silica,

[0122] 3-4.5 parts of polytetrafluoroethylene modified polyethylene wax powder;

[0123] The core layer is made of raw materials comprising the following parts by weight:

[0124] 75-85 parts of polypropylene,

[0125] 12-16 parts of colorless transparent epoxy resin,

[0126] 7-9 parts of polymers of 2,5-furandione, ethylene and 1-propylene,

[0127] 4-6 parts of oxidized polypropylene wax,

[0128] 3 to 4 parts of nano silicon di...

Embodiment 2

[0158] A multi-layer co-extruded heat-sealable polypropylene film, said multi-layer co-extruded heat-sealed polypropylene film is directly co-extruded from a surface layer, a core layer, and an inner layer three-layer structure;

[0159] Wherein, the surface layer is made of raw materials comprising the following parts by weight:

[0160] 70 parts of ethylene-propylene-butene terpolymer,

[0161] 12 parts of ethylene-butene copolymer,

[0162] 5 parts of oxidized polyethylene wax,

[0163] Modified mesoporous silica 13 parts,

[0164] 3 parts of polytetrafluoroethylene modified polyethylene wax powder;

[0165] The core layer is made of raw materials comprising the following parts by weight:

[0166] 75 parts of polypropylene,

[0167] 12 parts of colorless transparent epoxy resin,

[0168] 7 parts of polymers of 2,5-furandione, ethylene and 1-propylene,

[0169] 4 parts of oxidized polypropylene wax,

[0170] 3 parts of nano silicon dioxide;

[0171] The inner layer ...

Embodiment 3

[0197] A multi-layer co-extruded heat-sealable polypropylene film, said multi-layer co-extruded heat-sealed polypropylene film is directly co-extruded from a surface layer, a core layer, and an inner layer three-layer structure;

[0198] Wherein, the surface layer is made of raw materials comprising the following parts by weight:

[0199] 80 parts of ethylene-propylene-butene terpolymer,

[0200] 15 parts of ethylene-butene copolymer,

[0201] 7 parts of oxidized polyethylene wax,

[0202] Modified mesoporous silica 17 parts,

[0203] 4.5 parts of polytetrafluoroethylene modified polyethylene wax powder;

[0204] The core layer is made of raw materials comprising the following parts by weight:

[0205] 85 parts of polypropylene,

[0206] 16 parts of colorless transparent epoxy resin,

[0207] 9 parts of polymers of 2,5-furandione, ethylene and 1-propylene,

[0208] 6 parts of oxidized polypropylene wax,

[0209] 4 parts of nano silicon dioxide;

[0210] The inner laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com