Formula and preparation process for low-temperature-resistant high-elasticity polyurethane used for sealing

A technology with low temperature resistance and high elasticity, which is applied in the field of polyurethane materials, can solve the problems of low temperature resistance and elasticity, poor elasticity, etc., and achieve the effect of expanding the use temperature range, stable performance, and expanding the temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

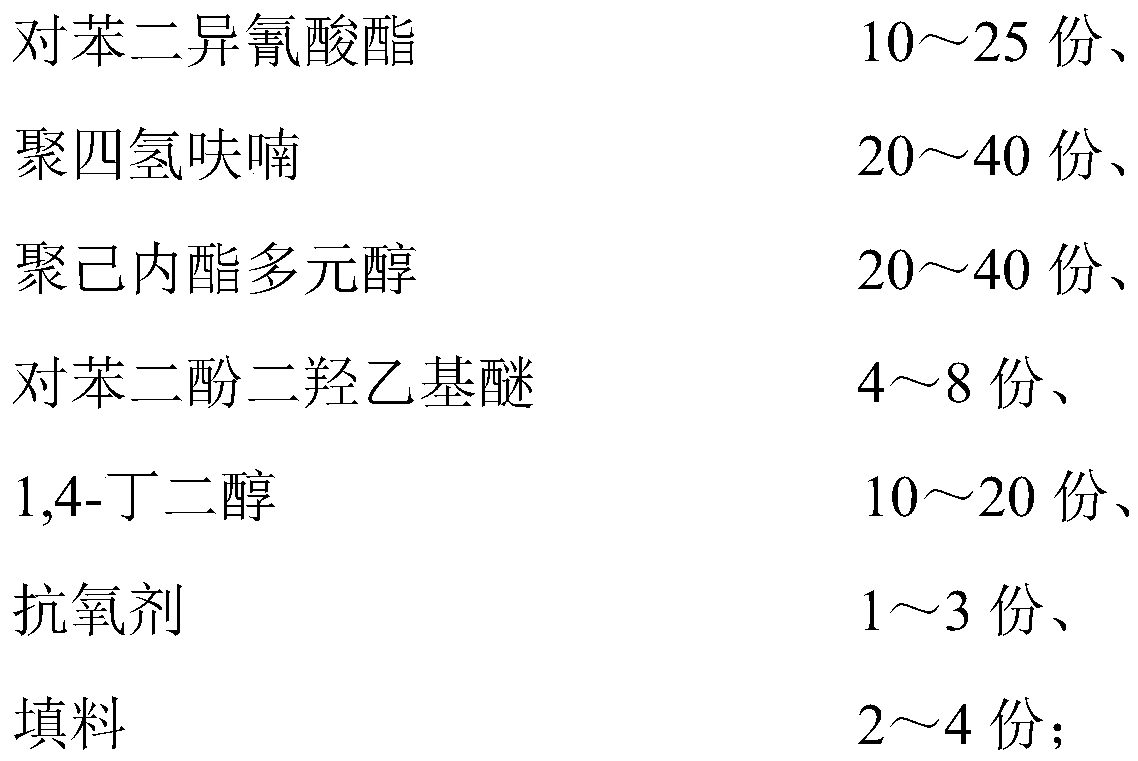

[0049] A low-temperature-resistant high-elastic polyurethane formula for sealing, comprising the following raw materials in parts by weight:

[0050]

[0051] The relative molecular mass of the polytetrahydrofuran is 1400-2000; the relative molecular mass of the polycaprolactone polyol is 1800-2200.

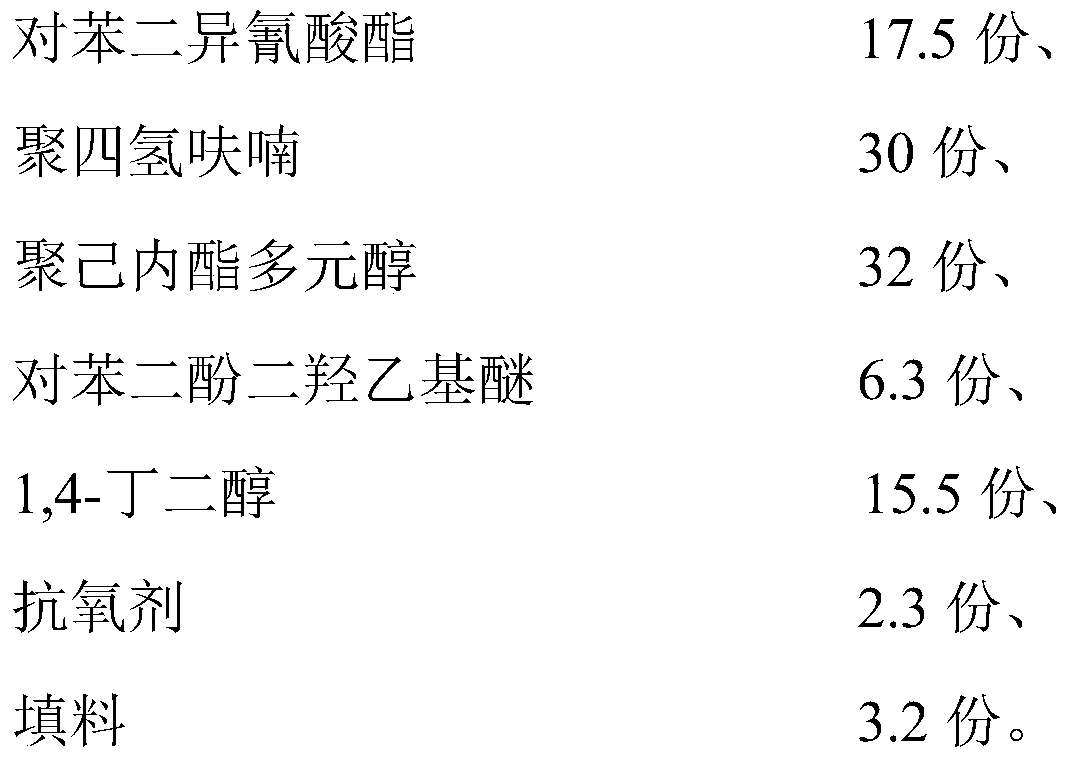

[0052] Preferably, the low-temperature-resistant high-elastic polyurethane formula for sealing includes the following raw materials in parts by weight:

[0053]

[0054]

[0055] The present invention also provides a preparation process of the low-temperature-resistant high-elasticity polyurethane for sealing comprising the following steps:

[0056] A. Take by weight: p-phenylene diisocyanate, polytetrahydrofuran, polycaprolactone polyol, hydroquinone dihydroxyethyl ether, 1,4-butanediol, antioxidant and filler;

[0057] B. Add polytetrahydrofuran and polycaprolactone polyol into the reaction kettle, stir at a medium speed of 500-800rpm, and control the temperature in t...

Embodiment 2

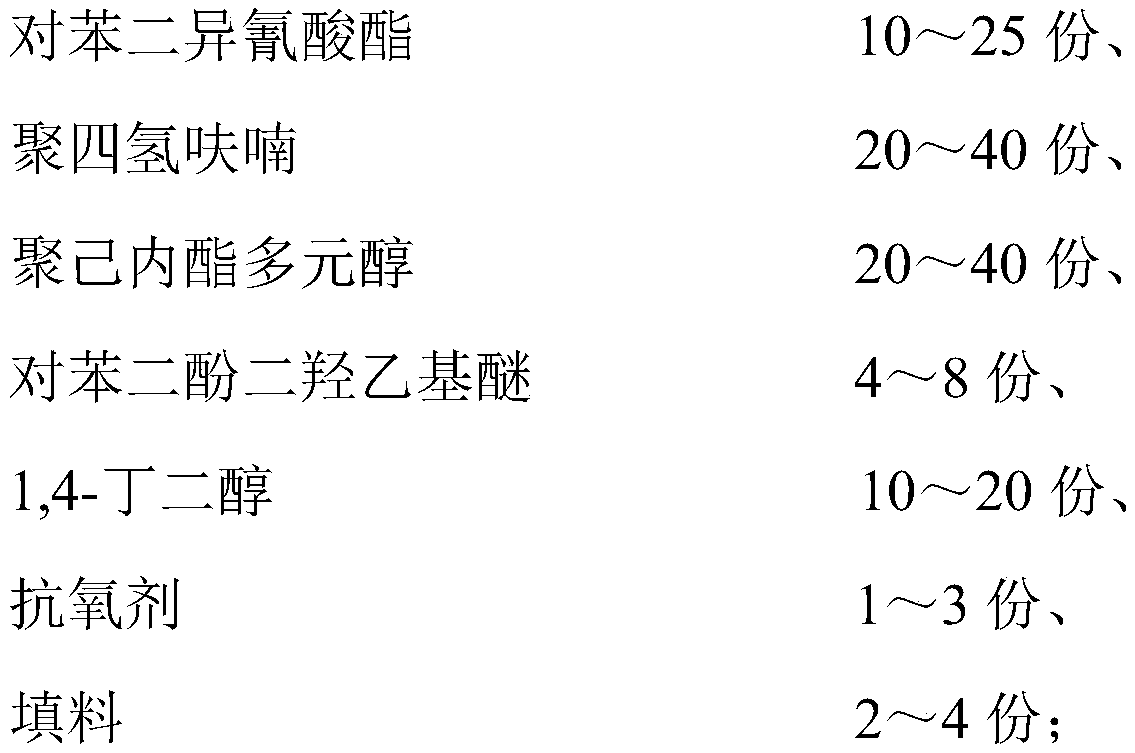

[0070] A low-temperature-resistant high-elastic polyurethane formula for sealing, comprising the following raw materials in parts by weight:

[0071]

[0072] The relative molecular mass of the polytetrahydrofuran is 1400; the relative molecular mass of the polycaprolactone polyol is 1800.

[0073] In this embodiment, the preparation process of the low-temperature-resistant high-elastic polyurethane for sealing includes the following steps:

[0074] A. Take by weight: p-phenylene diisocyanate, polytetrahydrofuran, polycaprolactone polyol, hydroquinone dihydroxyethyl ether, 1,4-butanediol, antioxidant and filler;

[0075] B. Add polytetrahydrofuran and polycaprolactone polyol into the reaction kettle, stir at a medium speed of 500rpm, and control the temperature in the reaction kettle at 102°C;

[0076] C, add antioxidant and filler again, adopt 2100rpm high-speed stirring and vacuumize, the temperature in the described reactor is controlled at 110 ℃;

[0077] D. After 1 h...

Embodiment 3

[0086] A low-temperature-resistant high-elastic polyurethane formula for sealing, comprising the following raw materials in parts by weight:

[0087]

[0088] The relative molecular mass of the polytetrahydrofuran is 2000; the relative molecular mass of the polycaprolactone polyol is 2200.

[0089] In this embodiment, the preparation process of the low-temperature-resistant high-elastic polyurethane for sealing includes the following steps:

[0090] A. Take by weight: p-phenylene diisocyanate, polytetrahydrofuran, polycaprolactone polyol, hydroquinone dihydroxyethyl ether, 1,4-butanediol, antioxidant and filler;

[0091] B. Add polytetrahydrofuran and polycaprolactone polyol into the reaction kettle, stir at a medium speed of 800rpm, and control the temperature in the reaction kettle at 98°C;

[0092] C, add antioxidant and filler again, adopt 2200rpm high-speed stirring and vacuumize, the temperature in the described reactor is controlled at 100 ℃;

[0093] D. After 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com