Negative ion antibacterial ES composite fiber and preparation method thereof

An anion antibacterial and composite fiber technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of non-durability, hard texture, and no antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

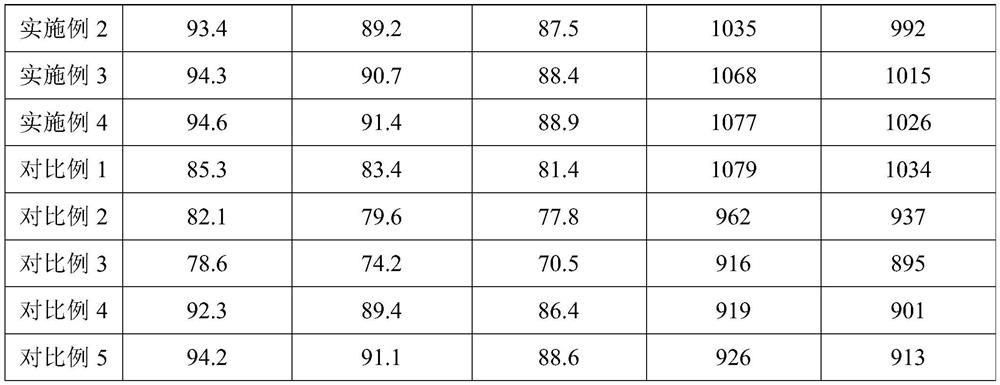

Examples

Embodiment 1

[0036] A negative ion antibacterial ES composite fiber, said negative ion antibacterial ES composite fiber has a skin-core structure, namely consisting of a core layer and a skin layer;

[0037] Wherein, the core layer includes the following raw materials in parts by weight: 80-90 parts of polypropylene, 8-11 parts of polyethylene, 12-16 parts of maleic anhydride grafted polypropylene;

[0038] The skin layer includes the following raw materials in parts by weight: 70-80 parts of polyethylene, 7-10 parts of ethylene-propylene copolymer, 6-8 parts of dibutyl maleate grafted polypropylene, 15-20 parts of ethylene-vinyl acetate copolymer 5-6.5 parts of crystal tourmaline powder, 2-2.6 parts of opal powder, and 1.5-2.0 parts of ivy powder.

[0039] In this embodiment, the core layer preferably includes the following raw materials in parts by weight: 85 parts of polypropylene, 9.5 parts of polyethylene, and 14 parts of maleic anhydride grafted polypropylene;

[0040] The cortex pr...

Embodiment 2

[0053] A negative ion antibacterial ES composite fiber, said negative ion antibacterial ES composite fiber has a skin-core structure, namely consisting of a core layer and a skin layer;

[0054] Wherein, the core layer includes the following raw materials in parts by weight: 80 parts of polypropylene, 8 parts of polyethylene, 12 parts of maleic anhydride grafted polypropylene;

[0055] The skin layer includes the following raw materials in parts by weight: 70 parts of polyethylene, 7 parts of ethylene-propylene copolymer, 6 parts of dibutyl maleate grafted polypropylene, 15 parts of ethylene-vinyl acetate copolymer, 5 parts of crystal tourmaline powder, Opal powder 2 parts, ivy powder 1.5 parts.

[0056] In this embodiment, the polyethylene is metallocene linear low density polyethylene.

[0057] In this embodiment, the maleic anhydride grafting ratio of the maleic anhydride grafted polypropylene is 3.8%.

[0058] In this embodiment, the dibutyl maleate grafting ratio of the...

Embodiment 3

[0068] A negative ion antibacterial ES composite fiber, said negative ion antibacterial ES composite fiber has a skin-core structure, namely consisting of a core layer and a skin layer;

[0069] Wherein, the core layer includes the following raw materials in parts by weight: 90 parts of polypropylene, 11 parts of polyethylene, 16 parts of maleic anhydride grafted polypropylene;

[0070] The skin layer includes the following raw materials in parts by weight: 80 parts of polyethylene, 10 parts of ethylene-propylene copolymer, 8 parts of dibutyl maleate grafted polypropylene, 20 parts of ethylene-vinyl acetate copolymer, 6.5 parts of crystal tourmaline powder, Opal powder 2.6 parts, ivy powder 2.0 parts.

[0071] In this embodiment, the polyethylene is metallocene linear low density polyethylene.

[0072] In this embodiment, the maleic anhydride grafting rate of the maleic anhydride grafted polypropylene is 4.5%.

[0073] In this embodiment, the dibutyl maleate grafting ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com