Antibacterial chitosan fabric and preparation method and product thereof

An antibacterial fabric and chitosan technology, applied in the field of textile fabrics, can solve the problems of affecting the mechanical properties of the fabric, poor antibacterial and antibacterial effects, and non-lasting antibacterial effects, and achieve the effects of simple operation, good antibacterial effect, and improved antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

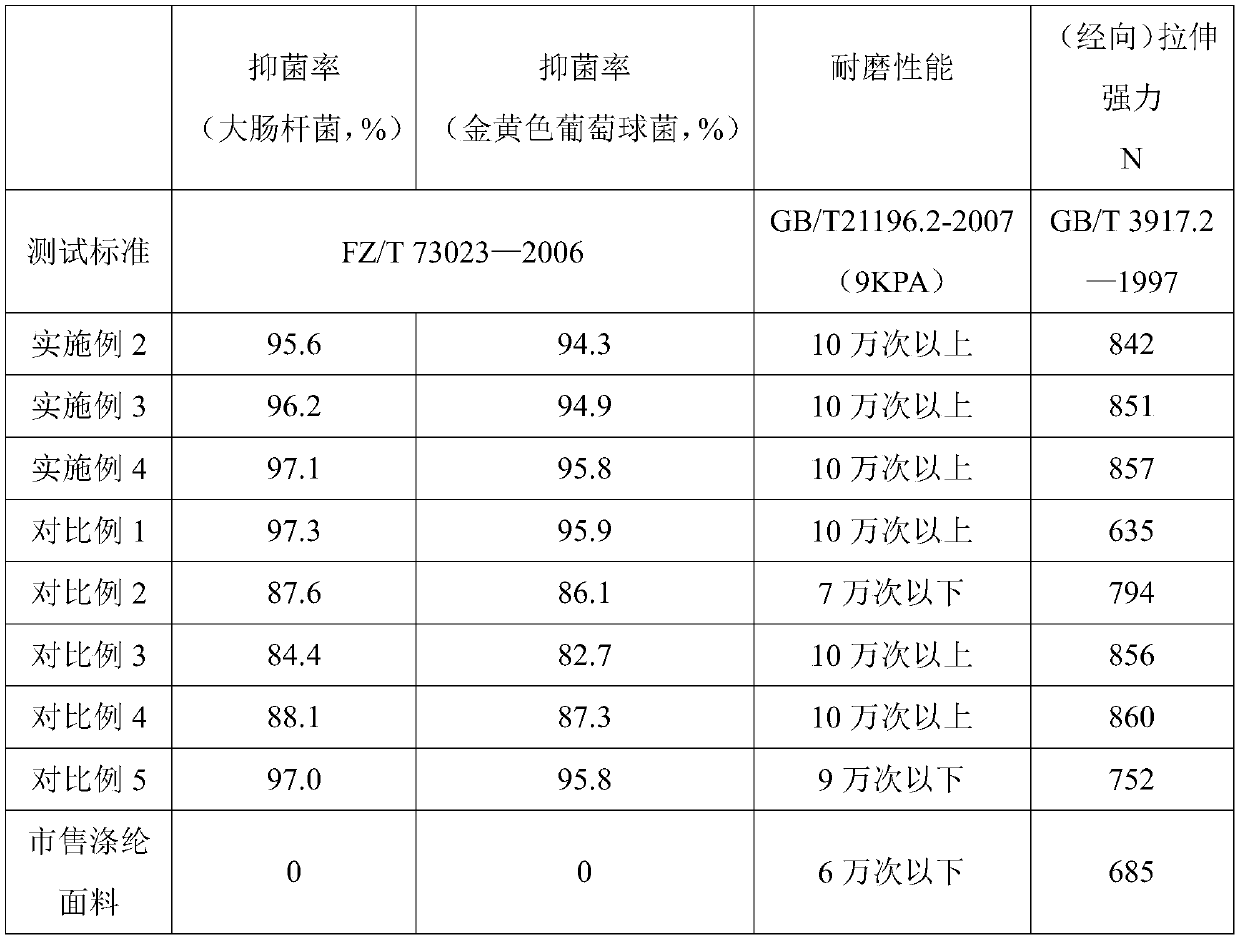

Examples

Embodiment 1

[0066] A kind of chitosan antibacterial fabric, described chitosan antibacterial fabric is made by knitting or weaving process by sheath-core composite filament;

[0067] The sheath-core composite filament includes a core layer and a skin layer;

[0068] The skin layer is coated on the outer surface of the core layer, and the cross-sectional profile of the skin layer is circular;

[0069] The ratio of the cross-sectional area of the core layer to the skin layer is 1: (0.7-0.8);

[0070]The core layer is made of raw materials comprising the following parts by weight:

[0071] 90-95 parts of polyethylene terephthalate,

[0072] 5-10 parts of polypentamethylene adipate;

[0073] The cortex is made of raw materials comprising the following parts by weight:

[0074] 4-8 parts of polyethylene terephthalate,

[0075] 86-92 parts of polypentamethylene adipate,

[0076] 1.6-2.0 parts of nano-graphene sheet,

[0077] 6-9 parts of chitosan,

[0078] 3 to 5 parts of diatomaceous...

Embodiment 2

[0106] A kind of chitosan antibacterial fabric, described chitosan antibacterial fabric is made by knitting or weaving process by sheath-core composite filament;

[0107] The sheath-core composite filament includes a core layer and a skin layer;

[0108] The skin layer is coated on the outer surface of the core layer, and the cross-sectional profile of the skin layer is circular;

[0109] The ratio of the cross-sectional area of the core layer to the skin layer is 1:0.7;

[0110] The core layer is made of raw materials comprising the following parts by weight:

[0111] 90 parts of polyethylene terephthalate,

[0112] 5 parts of polypentamethylene adipate;

[0113] The cortex is made of raw materials comprising the following parts by weight:

[0114] 4 parts polyethylene terephthalate,

[0115] 86 parts of polypentamethylene adipate,

[0116] 1.6 parts of nano-graphene sheets,

[0117] Chitosan 6 parts,

[0118] 3 parts diatomaceous earth,

[0119] Fumed silica 3 par...

Embodiment 3

[0134] A kind of chitosan antibacterial fabric, described chitosan antibacterial fabric is made by knitting or weaving process by sheath-core composite filament;

[0135] The sheath-core composite filament includes a core layer and a skin layer;

[0136] The skin layer is coated on the outer surface of the core layer, and the cross-sectional profile of the skin layer is circular;

[0137] The ratio of the cross-sectional area of the core layer to the skin layer is 1:0.8;

[0138] The core layer is made of raw materials comprising the following parts by weight:

[0139] 95 parts of polyethylene terephthalate,

[0140] 10 parts of polypentamethylene adipate;

[0141] The cortex is made of raw materials comprising the following parts by weight:

[0142] 8 parts of polyethylene terephthalate,

[0143] 92 parts of polypentamethylene adipate,

[0144] 2.0 parts of nano-graphene sheets,

[0145] Chitosan 9 parts,

[0146] 5 parts of diatomaceous earth,

[0147] Fumed silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com