Solvent-free release silicone oil with medium and heavy release force and preparation method of solvent-free release silicone oil

A solvent-free, heavy-stripping technology, applied in directions such as no pigment coating, can solve the problems of small application range, environmental and personnel hazards, poor adaptability, etc., and achieve the effects of high residual rate, low stripping noise, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

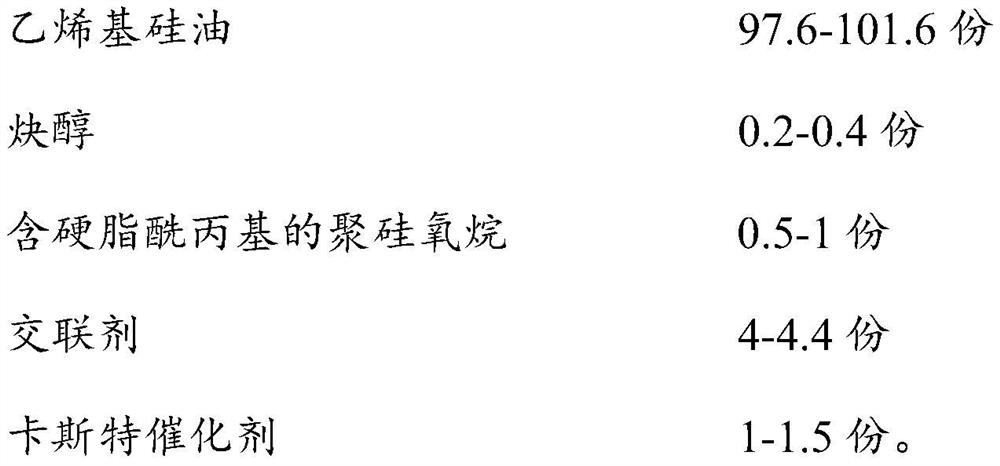

[0028] 99.8 parts of vinyl silicone oil, 0.2 parts of acetylenic alcohol, 0.5 parts of polysiloxane containing stearyl propyl group, 4.3 parts of crosslinking agent, and 1.5 parts of Castel catalyst.

[0029] In this example, vinyl silicone oil and acetylenic alcohol are the main ingredients of the solvent-free release silicone oil.

[0030] Wherein, the viscosity of vinyl silicone oil is 1000 mPa·s, and the mass fraction of vinyl is 1%.

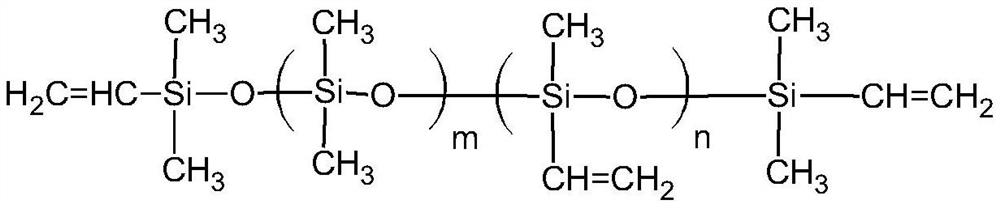

[0031] Among them, the structural formula of vinyl silicone oil is

[0032]

[0033] Wherein, m is 50≤m≤500, and n is 0≤n≤50.

[0034] Further, in this embodiment, the average structural formula of the vinyl silicone oil used is

[0035]

[0036] Among them, in the vinyl silicone oil, calculated according to parts by weight, the synthetic formula is: 1255.2 parts of octamethylcyclotetrasiloxane, 32.7 parts of tetramethyltetravinylcyclotetrasiloxane, 32.7 parts of tetramethyldivinyl disiloxane 12.1 parts of oxane, 7 parts of tetramet...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is:

[0052] 97.6 parts of vinyl silicone oil, 0.4 part of acetylenic alcohol, 1 part of polysiloxane containing stearyl propyl group, 4.4 parts of crosslinking agent, and 1 part of Castel catalyst.

[0053] Wherein, the viscosity of vinyl silicone oil is 800mPa·s, and the mass fraction of vinyl is 0.5%.

[0054] Among them, in the vinyl silicone oil, calculated according to parts by weight, the synthetic formula is: 1200 parts of octamethylcyclotetrasiloxane, 11 parts of tetramethyltetravinylcyclotetrasiloxane, 11 parts of tetramethyldivinyl disiloxane 10 parts of oxane, 5 parts of tetramethylammonium hydroxide alkali gum.

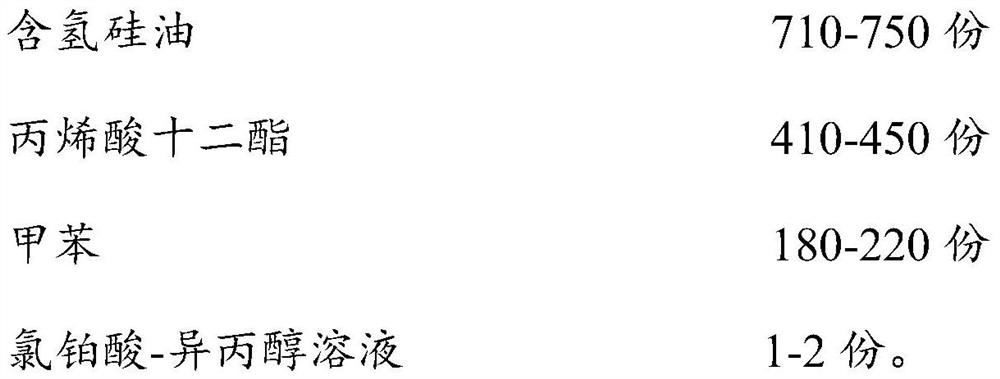

[0055] Among them, in the polysiloxane containing stearyl propyl group, the synthetic formula is calculated according to parts by weight: 710 parts of hydrogen-containing silicone oil, 410 parts of lauryl acrylate, 180 parts of toluene, chloroplatinic acid-isopropanol solution 2 servings.

...

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is:

[0059] 101.6 parts of vinyl silicone oil, 0.4 parts of acetylenic alcohol, 0.5 parts of polysiloxane containing stearyl propyl group, 4 parts of crosslinking agent, 1.5 parts of castor catalyst, and fluorine-containing hydrosiloxane.

[0060] Wherein, the viscosity of vinyl silicone oil is 1200mPa·s, and the mass fraction of vinyl is 2%.

[0061] Among them, in the vinyl silicone oil, calculated according to parts by weight, the synthetic formula is: 1300 parts of octamethylcyclotetrasiloxane, 85 parts of tetramethyltetravinylcyclotetrasiloxane, 85 parts of tetramethyldivinyl disiloxane 15 parts of oxane, 8 parts of tetramethylammonium hydroxide alkali gum.

[0062] Among them, in the polysiloxane containing stearyl propyl group, the synthetic formula is calculated according to parts by weight: 750 parts of hydrogen-containing silicone oil, 450 parts of lauryl acrylate, 220 parts of toluene, chloroplatinic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com